VERTICAL FOCUS | Automotive

On the Road to Sustainable Mobility

Mercedes-Benz, working with Circulor, a startup specializing in blockchain technology, is conducting a pilot project dubbed Ambition 2039 that aims for a carbon-neutral new passenger car fleet in less than 20 years. This transformation will require detailed knowledge of all climate-relevant processes associated with the entire vehicle value chain.

In a first step, Mercedes-Benz is creating transparency of carbon dioxideemissions and using secondary material in the supply chain. The project partners will first focus on cobalt, which enters the supply chain from recycling facilities. A blockchain-based system maps the production flow of the materials as well as the associated carbonemissions.

In the long term, Mercedes-Benz is pursuing the goal of a circular economy and is working to close material cycles. For this purpose, the mapping of the material flow also records the amount of recycled material in the supply chain.

The network also displays whether Mercedes-Benz’s sustainability requirements in terms of working conditions, human rights, environmental protection, safety, business ethics, and compliance are passed on to all companies involved. The automaker calls on its direct suppliers to comply with these standards, as well as carry the provisions into upstream value chains and monitor their compliance.

Recalling the Need for Better Supply Chain Management

Product recalls are an emerging risk for auto original equipment manufacturers (OEMs), compounded by the complexity of global decentralized supply chains, stringent government safety mandates, and increasing cost pressure for suppliers.

Global auto companies source components from numerous manufacturers worldwide. Managing this complex global supply chain is an increasingly difficult challenge for OEMs. The January 2020 recall of 63 million Takata air bags reveals major gaps in the auto industry’s supplier relationship management practices.

Most supplier programs are built only for Tier 1 suppliers; more than 70% of OEMs have zero visibility of their Tier 2 and 3 suppliers, finds Research and Markets’ latest report. The immediate need is for auto companies to develop robust, responsible relationships with suppliers to reduce the risk of recalls.

A strong OEM-supplier governance mechanism will also ensure socially responsible recalls and quicker recovery from a recall crisis. Strategic supply chain management, supported by supply chain analytics and software systems for supplier tracking and management, is crucial. Especially against the backdrop of the commercialization of autonomous and smart cars, the focus on "zero-defect" manufacturing should gain more significance.

Auto OEMs also need to move from reactive firefighting to recall prevention by stepping up quality-management strategies from single quality processes to integrated quality systems, the report concludes.

Shifting to Smart Factories

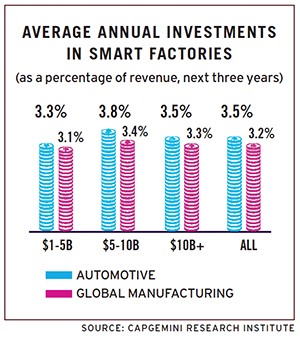

The auto industry is motoring ahead in smart factory adoption, and is set to increase investment by more than 60% in the next three years, resulting in productivity gains of more than $160 billion, according to a new report from theCapgemini Research Institute.

Key points of the report include:

- The automotive industry has exceeded previous expectations on smart-factory development.

- Automotive is moving faster than other industries to convert factories into smart facilities.

Projected investment levels and productivity gains related to smart factories are significant, the report finds, but only 10% of auto firms are ready to take advantage through deployment.

The industry has set stiff performance targets for smart factories, but these are a long way from being fulfilled: Of the 35% productivity improvement target, just 15% has been achieved. Only an 11% gain occurred in overall equipment effectiveness and reduced stocks/work in process, compared to targets of 38% and 37%, respectively. Many initiatives are yet to be scaled fully.