Parts & Parcel

Driven by an increase in e-commerce, global parcel volume grew from 74.4 billion shipments in 2017 to 87 billion last year. On average, 23 parcels per person were shipped globally, and 2,760 parcels were shipped every second, according to the Pitney Bowes Parcel Shipping Index. Collectively, China, the United States, and Japan lead the global […]

Read More

The Death of Your Profession?

In a few short years you won’t be employed. That’s right, if you work in the supply chain management field, and have a decade or so until you retire, it’s time to dust off your resume and consider other career paths. That’s according to commentary authors Allan Lyall, Pierre Mercier, and Stefan Gstettner in a […]

Read More

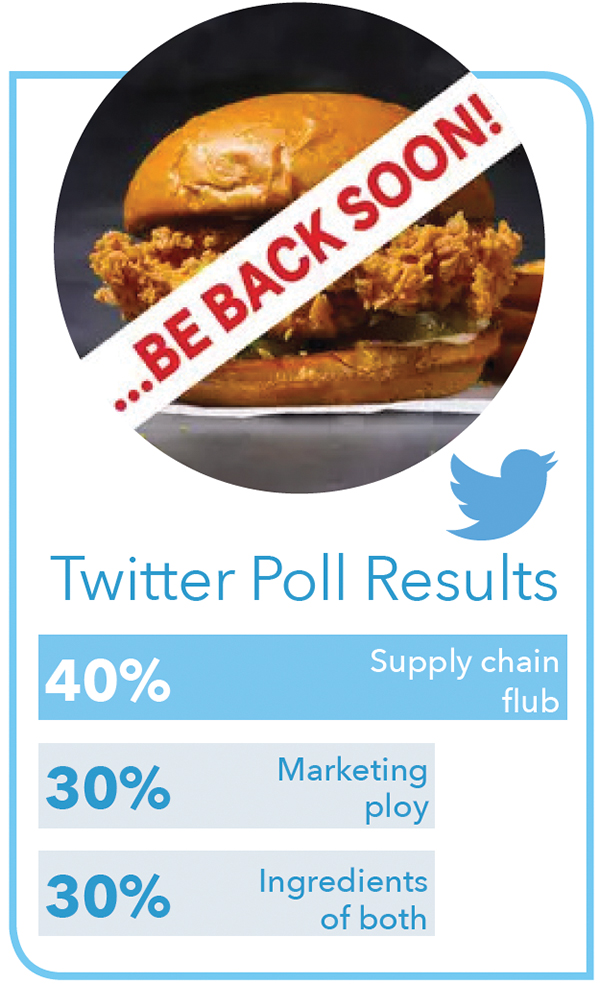

GOOD QUESTION | Popeyes chicken sandwich shortage: Supply chain fail or marketing savvy?

All marketing strategy in my humble opinion. Like a limited release of Jordan sneakers and then a re-release at a later date. Milton O’Quinn III National Operations Manager, RPM It’s a great lesson—companies should do more data analytics to better understand how consumers respond to social media marketing and build up supply chain agility and […]

Read More

Drilling Deeper Into Your Supply Chain

Data analytics is the science of examining raw data to help draw conclusions about information. When applied to the supply chain, it allows companies to drive insight, make better business decisions, and verify or disprove existing models or theories. Data analytics breaks out into the following categories: Descriptive analytics. In supply chain, descriptive analytics helps […]

Read More

Using Real-Time Tech to Mitigate Risk

Mitigating risk is one of the most challenging aspects of managing shipping logistics. The good news: Help is available.

Read More

3PLs Add Value

Increasing consumer expectations, market uncertainty, and other recent trends, have only enhanced the value 3PLs bring to shippers. From technology innovations to process insights, here are the ways 3PLs unlock and increase supply chain efficiencies.

Read MorePushing the Speed Limit: Increasing Operational Efficiencies with Digital Payments

Logistics is an industry that depends on speed, efficiency and accuracy for virtually every aspect of its business but one – payments. Up and down supply chains, paper checks remain the dominant form of payment, requiring manual data entry that slows every stage of the process, particularly when it comes to towing and warehouse operations. […]

Read More

Tech Can Turn Your Supply Chain Into a Well-Oiled Green Machine

The majority of your customers want to make their consumption habits more sustainable and their loyalty will only go so far if your brand doesn’t adapt. Despite growing demand for sustainable products, and consumers who value green practices over the green in their wallets, CPG brands are falling short. If they want to succeed, smart […]

Read More

Supply Chain Conferences Complement Logistics Job Training and Education

The optimal way to understand the intricacies of today’s supply chain environment is to participate in an educationally focused transportation conference.

Read More

How Smarter, Stronger Supply Chains Improve the Customer Experience

Companies today are increasingly leveraging digital technologies like artificial intelligence (AI), deep learning, and machine learning (ML) to build smarter supply chain operations. They are turning “big supply chain data” into real insights that improve efficiency, bring products and services to market faster, and deliver differentiating customer value, all key to remaining competitive in the […]

Read More