The End of Cost-Plus: A Legacy Pricing Model in a High-Performance Supply Chain

A Case for Performance-Based Pricing

For years, the dominant pricing structure in third-party logistics contracts has been the cost-plus model. Under this approach, customers pay for labor and overhead, plus a fixed margin. It’s straightforward and familiar—but is it still the best tool for today’s supply chain?

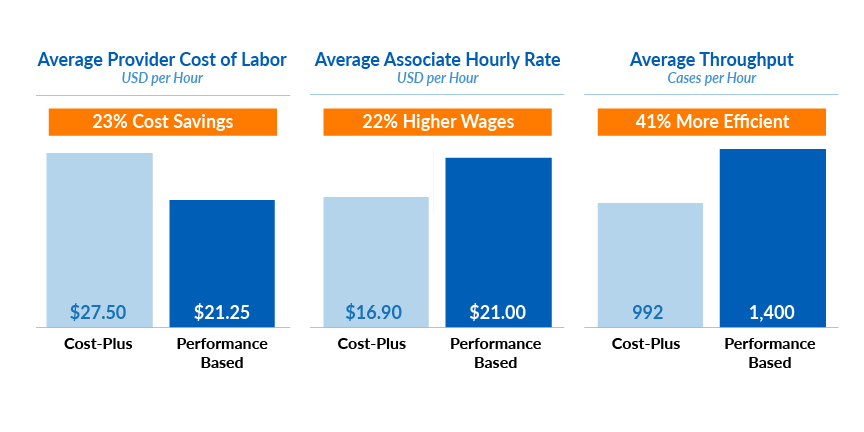

When it comes to 3PL contracts, not all pricing models deliver the same results. And as supply chains evolve with the times, so should the commercial models that underpin them. Increasingly, logistics leaders are turning to pay-for-performance or activity-based pricing as a more effective way to align incentives, reduce waste, and drive continuous improvement.

A performance-paid or activity-based pricing model aligns your costs directly with your throughput: cases picked, pallets moved, trailers loaded. Your costs are structured around work performed rather than hourly estimates. That simple difference can transform your cost structure and your bottom line.

Cost-Plus: Familiar, But Flawed

Cost-plus, often implemented as an “open-book” agreement, may offer transparency—but it rarely guarantees efficiency. Because costs are largely fixed, the model lacks built-in motivation for productivity gains. If volumes dip, costs don’t necessarily follow. And if performance suffers, the customer often absorbs the risk.

In a cost-plus environment, labor inefficiencies, absenteeism, or even poor process design can go unaddressed because the financial incentives don’t push toward improvement. That can be a costly blind spot, especially in operations where demand is variable or margins are tight.

Pay-for-Performance: Aligned and Accountable

By contrast, a pay-for-performance model, often called cost per unit or activity-based costing, shifts the focus from inputs to outcomes. Customers pay a pre-agreed rate per activity—per case picked, pallet moved, or trailer loaded—tying costs directly to throughput, so labor costs flex with your volume. Labor is compensated based on output, not attendance, and performance is measured using engineered standards.

This structure builds accountability from the ground up. When workers are paid based on how much they produce, efficiency becomes a shared priority. From the floor to the management team, everyone is incentivized to hit targets, reduce errors, and continuously improve.

Real-World Advantages

In environments that have transitioned from hourly labor to activity-based compensation, the improvements are often dramatic. Companies have reported reductions in overtime, better order accuracy, and measurable decreases in product damage.

Perhaps even more importantly, performance-based models bring agility. As demand fluctuates due to seasonal peaks, promotions, or market shifts, activity-based pricing automatically scales with volume. This flexibility reduces the need for overstaffing during slow periods and mitigates the chaos of last-minute hiring during surges.

Choosing the Right Model

Gartner’s research echoes this: while cost-plus and closed-book models work for steady, predictable volumes, variable and activity-based pricing unlock real value for dynamic operations. In an environment where every dollar matters, paying for productivity drives structural cost reduction and continuous improvement.

When to Consider a Pay-for-Performance Model

Pay-for-performance isn’t a fit for every operation. It works best where:

- Volume is variable and throughput is measurable

- Clear performance standards can be defined

- Data systems can support real-time tracking

- All parties are aligned on shared goals

For operations seeking greater cost control, improved service levels, and a culture of accountability, pay for performance offers a compelling alternative to legacy pricing structures.

Rethinking the 3PL Relationship

Ultimately, a pay-for-performance model isn’t just about pricing; it’s about partnership. It turns the customer-provider relationship into a joint pursuit of operational excellence. When incentives are aligned and results are measured, performance becomes a mutual priority—not just a contractual obligation.

In today’s high-stakes supply chain, that alignment can make all the difference.

From performance-driven labor solutions to warehouse management, high-touch transportation, and last-mile fulfillment, Capstone Logistics offers a fully integrated suite of solutions underpinned by a best-in-class technology and operating platform. Learn more at www.capstonelogistics.com