TAKEAWAYS: Shaping the Future of the Global Supply Chain

What does the current landscape of corporate sustainability efforts look like? Here’s a glimpse at top challenges for emissions reduction initiatives and other supply chain trending topics.

Sky Miles

We’re one step closer to the future after Alef, a startup developing a flying car, was recently granted Special Airworthiness Certification by the Federal Aviation Administration.

Alef’s all-electric Model A can drive on roads and also vertically take off and land. It has a driving range of 200 miles and a flight range of 110 miles. The gimbaled cabin of the vehicle remains steady and stable during flight since it’s mounted to a rigid frame that allows it to pivot. The propellers are enclosed within the frame to enhance safety and cut down on noise.

The Model A currently is designed to accommodate one to two passengers, but the company says it is developing a Model Z four-person sedan with increased range. As testing continues, Alef says it remains on track to deliver the first Model A vehicles by the fourth quarter of 2025. The Model Z will have to wait until 2035.

Oh, the price? A mere $300,000.

Don’t Get Held Up for Ransom

To avoid supply chain ransomware attacks, follow this advice from Adam Scamihorn, product director, InterVision:

1. Deploy proactive cybersecurity defense measures. The only way to prevent an attack—or curtail its impact on business continuity—is to enact a ransomware protection strategy.

2. Include zero-trust security in your cyber-defense practices. Zero-trust systems require robust and frequent user authentication through multi-factor authentication and single sign-on protocols, regardless of where the user is geographically located.

3. Work with a cybersecurity partner, either through an internal position like head of cybersecurity, a third-party vendor, or both.

4. Procure a ransomware response strategy. Evaluate and test the response strategy with both desktop exercises and disaster recovery testing that utilizes a secure gapped recovery site with immutable data repositories.

5. Consider a cyber insurance plan. Cyber insurance covers some losses associated with a ransomware breach, including direct damages stemming from encryption or data loss.

6. Evaluate your suppliers’ cybersecurity practices. Consult with suppliers to ensure full visibility into their ransomware response plan and general cybersecurity measures.

7. If breached, note the damage and file a report. Pinpoint all affected devices and categorize impacted data. Work with legal counsel to determine the scope of legal and regulatory concerns based on the data impacted. This will inform the next appropriate steps to take.

8. When necessary, address ransomware appropriately. It is never wise to pay a ransom. Instead, focus on restoring device functionality expeditiously.

9. Inform stakeholders if a breach occurs. Work with legal counsel and develop an appropriate communication strategy. Be clear and upfront when informing top stakeholders of the damage and its possible ramifications.

10. Review internal processes and make improvements after a breach. Identify where the ransomware entered and fortify that gap. Invite outside parties to review security protocols and ensure that future ransomware attacks fail.

The full article is here.

Ryder Rides AI Wave

To prepare for the coming artificial intelligence (AI) wave, Ryder Systems has established Baton, A Ryder Technology Lab, based in Silicon Valley.

Baton’s mission is to pioneer customer-facing technologies to revolutionize how Ryder customers interact with their transportation and supply chain networks. These technologies will digitize and optimize networks at a level not currently available in the industry.

Leading Ryder’s innovation lab are Andrew Berberick and Nate Robert, co-chief product and technology officers for Ryder. The two founded San Francisco-based startup Baton, which was known for the development of a proprietary logistics technology focused on optimizing transportation networks. Ryder acquired the startup in 2022.

Baton’s first challenge is to create a first-of-its-kind, AI-powered digital platform and optimization engine that facilitates a new, integrated approach to managing transportation networks for customers where seasonality and fluctuating demand inhibit the continuous use of resources.

Ryder’s Nate Robert (left) and Andrew Berberick at Baton. (Photo: Business Wire)

Tech Adoption on the Rise

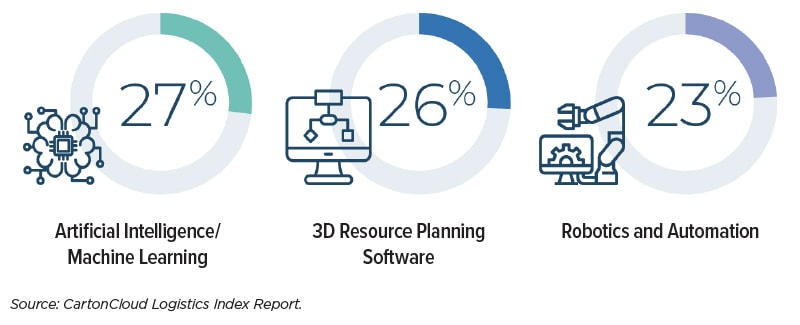

Innovative technology is on the rise and companies are ready to invest. The top technologies for investment in the near future are artificial intelligence/machine learning and 3D resource planning software, coming in ahead of electric vehicles, robotics, and new WMS/TMS software, according to the latest CartonCloud Logistics Index Report.

Of nearly 2,000 respondents surveyed, 27% say their business is likely to invest in artificial intelligence/machine learning in the coming months. This was closely followed by 3D resource planning software at 26%, and robotics and automation at 23%.

Anticipated Volume Growth Lifts Intermodal Outlook

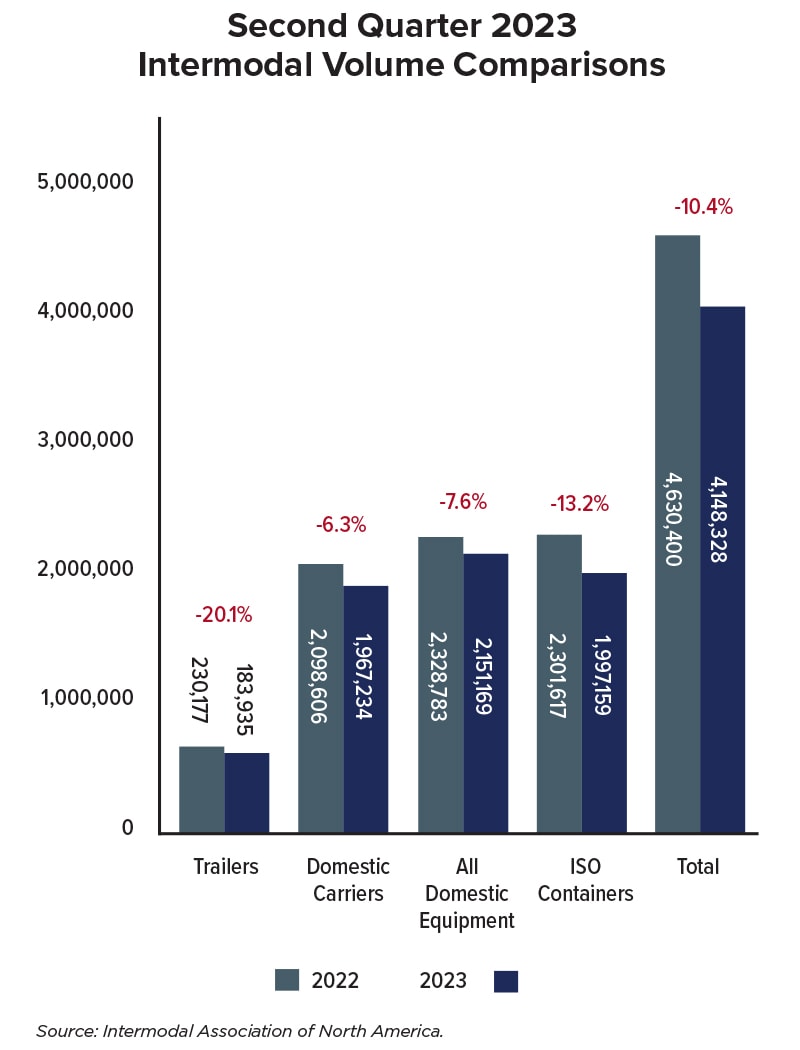

Total intermodal volumes fell 10.4% year-over-year in the second quarter of 2023, according to the Intermodal Association of North America (IANA). All segments showed declines: domestic containers, 6.3%; international containers, 13.2%; and trailers, 20.1%.

“Slower year-over-year demand for goods and a competitive freight environment have taken its toll for a second quarter,” says Joni Casey, president and CEO of IANA. “On the other hand, the numbers suggest a later peak this year and an improved picture for the second half of 2023.”

The seven highest-density trade corridors, which collectively handled more than 60% of total volume, were all down in the second quarter. Total intermodal marketing company volume fell 31.9% year-over-year in Q2, with intermodal traffic down 16.5% and highway loads down 39.7%.

CEOs Set Supply Chain Priorities

A majority of CEOs are spending more time on supply chain issues, finds the 2023 Supply Chain Barometer from procurement and supply chain consultancy Proxima.

The research also reveals that:

- Supply chain issues remain a headache. More than half (52.6%) of CEOs say they expect to spend more time on supply chain issues in the coming 12 months.

- Human rights issues are a key concern. More than two-thirds of CEOs (70.3%) say they are concerned about the potential for human or labor rights issues in their supply chain.

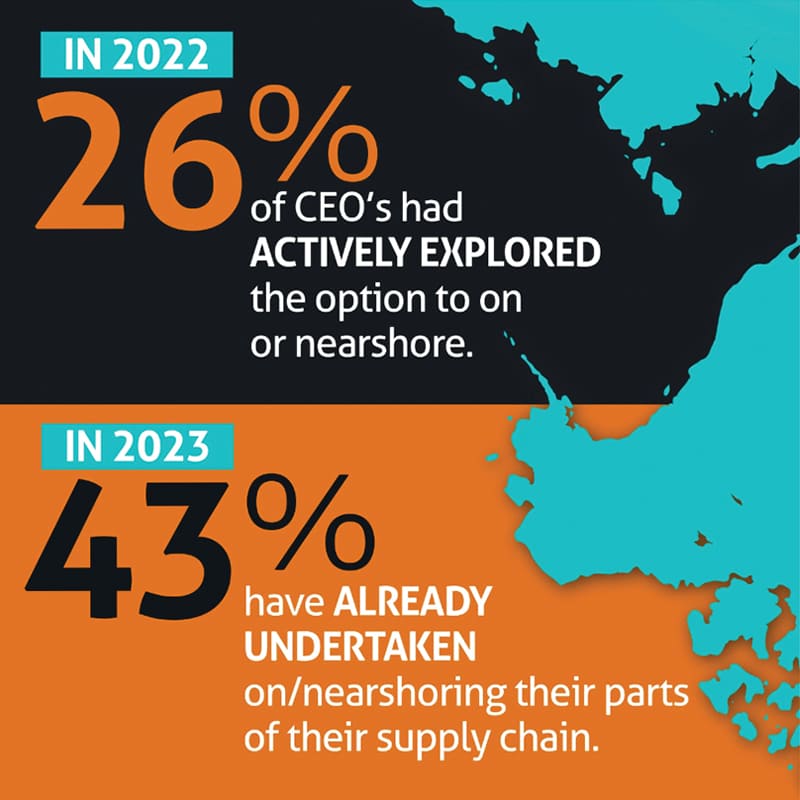

- Global supply chains are being rewired. In last year’s Supply Chain Barometer, just over one-quarter (26%) of CEOs said they had actively looked at on- or nearshoring some or all of their supply chains. This year’s results find that 4 in 10 (44.6%) CEOs in the United States who have a resilience problem are already either onshoring or considering it as an option, and a similar ratio (39%) are looking seriously at nearshoring.

- Progress is slow on decarbonization. The research shows that just over one-third of U.S. CEOs (34%) say they have a formal business plan for decarbonization, and 34% have begun strategic collaboration conversations with their suppliers.

Weaving CO2 Into Yarn

Walmart is teaming up with a California startup to test technology that removes carbon dioxide from its supply chain, with plans to eventually turn that CO2 into yarn for clothing.

As part of a pilot project with San Leandro-based Rubi Laboratories, Walmart will identify factories in its supply chain where carbon dioxide in waste gases can be captured using Rubi’s reactor systems.

The majority of the world’s captured CO2 is currently used for oil extraction, according to the Global CCS Institute, but Rubi’s system uses biochemical processes to convert the gas to cellulose, the main substance in the walls of plant cells. It’s a technique inspired by the way trees use carbon dioxide to grow.

That cellulose is used to produce lyocell yarn, which can be made into textiles. After performance testing, Walmart and Rubi plan to develop a prototype apparel collection. The pilot project runs through the end of 2024.

Top 3 Emissions Challenges and Priorities

What does the current landscape of corporate sustainability efforts look like? According to Optera’s 2023 trend report, Corporate Emissions in 2023: Large Organizations’ Top Challenges & Priorities, key trends include:

1. Emission reduction and regulatory compliance are top priorities. One-third of respondents report emissions reduction project implementation as the most pressing task this year. Compliance with regulations and verification comes close behind, with 25% of respondents citing it as their top priority.

2. Emission inventory processes are on the rise. The study reveals that 72% of organizations have undergone at least one emission inventory process.

3. Sustainability leaders are concerned about inaccurate emissions data. Fewer than 30% of respondents use tools that address the most common data issues. Incomplete and inaccurate data is holding back sustainability leaders from comprehensive, high-fidelity emissions data collection and analysis.