Top 20 AI Applications in the Supply Chain

Artificial intelligence can help with everyday supply chain tasks—say filling out customs paperwork—as well as guide supply chain planning and decision-making, enabling demand-driven responsiveness.

For small to mid-sized businesses and global corporations alike, artificial intelligence (AI) has far-ranging supply chain applications. AI-enabled solutions can ingest vast reserves of supply chain data, spot patterns, and generate human-sounding advice. And they can learn on the job—integrating with other technologies to sharpen their capabilities over time.

Here is a snapshot of how AI is currently being developed in supply chains:

1. Enabling supply chain visibility.

AI can work with Internet-of-Things (IoT) sensor inputs to provide visibility into supply chains. For example, Roambee’s AI-powered platform combines real-time IoT sensor information with data streams from carriers, ports, airport operations, rail lines, traffic reports, and weather forecasts.

The platform then transforms this data into predictive and contextual business signals, insights, and forecasts, such as replenishment triggers and quality compliance predictions.

2. Sourcing materials for manufacturing.

Companies can source parts faster at a competitive price with AI-powered supply management platforms, such as LevaData, which helps companies including Bose make data-based decisions about their direct materials sourcing.

LevaData provides manufacturer lead times in several commodity areas, letting companies identify alternative suppliers to ensure supply continuity. Via its dashboard, it breaks down spend data and provides recommendations so supply chain teams can detect patterns and savings opportunities.

3. Demand forecasting and planning.

AI can power forecasting engines thanks to its ability to process massive amounts of data and generate predictions based on this information.

For example, freight technology provider Loadsmart embedded a generative AI tool in its freight management platform ShipperGuide. Called CoPilot, the enhancement allows companies to generate reports, maps, and charts based on their shipping data. Shippers interact with the platform by stating questions.

One shipper reporting benefits from AI is American Tire Distributors (ATD), which supplies tires, wheels, and tools to the automotive market. The company deployed ToolsGroup Service Optimizer 99+ (SO99+), which has an AI-powered probabilistic forecasting engine, to gain insights into demand behavior.

The forecasting engine let ATD move from fixed forecast intervals to dynamic planning. The solution increases forecast collaboration with its suppliers and end retailers so the ATD team can make more demand-responsive decisions.

4. Managing inventory.

The demand forecasting capabilities of AI come in handy for optimizing inventory turns and reducing stockouts, enabling retailers and manufacturers to understand the seasonality of stock-keeping units.

For instance, Gaviota, an automated sun protection and shutter maker, deployed the SO99+ solution from ToolsGroup and achieved a 43% reduction in stock levels, slashing inventory from 61 to 35 days.

The SO99+ software defined the optimal mix of inventory across the manufacturer’s supply chain to achieve service level targets.

Gather AI is another AI-powered inventory management solution. It deploys drones that fly through warehouses to photograph inventory stored in pallet locations.

The AI reads barcodes, text, and other information in the images and automatically compares it with what’s in the warehouse management system (WMS), providing warehouse managers with real-time inventory data via a dashboard.

5. Identifying shipment delays.

Generative artificial intelligence can make it easier for companies to keep tabs on their shipments and stay on top of potential delays.

For instance, shippers can track cargo from container loading to store door delivery with Maersk’s AI-enabled reefer visibility assistant Captain Peter, which works with its remote container management system.

Additionally, project44, a supply chain visibility platform, is using its dataset gathered from tracking 1 billion shipments representing $1 trillion in customer inventory to enable Movement GPT, its new AI within its Movement platform, to respond to shipper queries.

Shippers can ask Movement GPT: “Which of my shipments are impacted by weather in northern Europe?” and “Do I have more reliable routing options for my next shipment?”

6. Predicting production bottlenecks and disruptions.

AI can predict raw material shortages years in advance. “AI can help companies prevent production bottlenecks by monitoring current and future availability levels of raw materials based on news, weather, and other available data,” says Jason Hehman, client partner at TXI, a provider of digitalization products.

“For example, say there’s a historic drought in the Southeastern United States. That won’t impact the timber supply for two or three years, but AI could leverage rainfall data to flag that crimp in advance,” he notes.

In short, AI-enabled tools can provide a roadmap to navigate uncertainty.

“By flagging product movement trends, creating heatmaps, and monitoring for broader supply chain disruptions, the AI can serve as a personal copilot and make users more effective in their jobs,” says Mike Sigler, senior director of customer success at the Nexer Group, an information technology services consultancy.

“For example, Copilot (editor’s note: not to be confused with Loadsmart’s CoPilot) in the Microsoft Supply Chain Center can identify potential supply chain disruptions like natural disasters, civil unrest or geopolitical clashes, or lagging economic indicators. From there, Copilot can automatically flag these events, show the users which customers are impacted, and create email messages to reroute purchase orders or check-in on customer contacts,” notes Sigler.

7. Improving responses to cargo theft.

Cargo theft prevention efforts will get a major boost from AI, which can help improve incident response times.

For example, Overhaul, a supply chain visibility, risk, compliance, and insurance solution, launched an AI feature called RiskGPT in its platform to allow users to quickly respond to in-transit shipment risk.

Because RiskGPT’s model is trained on Overhaul’s data, shippers can get an answer with details and contextual accuracy when they ask RiskGPT how to respond to a specific event. They can manage and mitigate a greater volume of risks with the tool.

Says one Overhaul client, Kok Ee Lian, global supply chain director at Dyson: “RiskGPT could be a game-changer with the potential to significantly improve our ability to manage risk with real-time response and corrective action—enabling us to better ensure the safety and security of our cargo.”

8. Selecting and managing suppliers.

The request-for-proposal process can be streamlined with AI. For instance, Verusen’s Trusted Supply application can improve the match rate for materials requested by manufacturers and other companies, enabling suppliers to respond promptly through its natural-language interface.

Another solution that harnesses AI is Procureship, an e-procurement platform for buyers of marine equipment, services, and solutions. It recommends suppliers through its machine learning algorithm and marketplace of service providers to make the purchasing process faster and more streamlined.

“When managed properly, artificial intelligence can improve supplier relationships through real-time data visibility,” says Spencer Shute, principal consultant at Proxima. “AI can allow companies and their suppliers to work in harmony, reducing the risk of supply and demand inaccuracies and offering a transparency that is difficult to achieve with competing priorities.”

9. Streamlining inbound logistics.

AI can help logistics service providers (LSPs) optimize assets for the movement of shippers’ materials or components from suppliers or vendors to their facilities.

For example, a major auto manufacturer is piloting nuVizz’s RoboDispatch Solution in its inbound logistics operations. In this pilot program, RoboDispatch automates the dispatch process for the movement of full and empty trailers from parts supplier locations to its manufacturing plants.

Leveraging AI and machine learning, the RoboDispatch Solution matches delivery assets to delivery demand in real time. The solution provides a portal for LSP customers to enter orders. It then automatically assigns customer orders to the most suitable contract or fleet driver to pick up and deliver the order on time.

10. Load planning.

AI can help companies plan loads and create a more balanced transportation plan so they can work with preferred carriers and ensure adequate storage space and labor availability across their sites.

For instance, the LevelLoad solution from ProvisionAI analyzes shipment patterns and identifies spikes in demand over the next 30 days. The system can then adjust by shipping some products early or holding less-needed items a day or two.

One LevelLoad customer is Kimberly-Clark, where the solution is run nightly, says Dr. Jeffrey Schutt, chief scientist at ProvisionAI. The solution helps the consumer products giant even out loads and “has resulted in substantially higher tender acceptance by their preferred carriers, significantly reduced transportation costs, and more efficient operations at their distribution facilities,” Dr. Schutt says.

AI-enabled short-range transportation planning helps optimize loads and increase efficiencies. “Using reinforcement learning, we can construct realistic candidate loads very quickly that know that bricks can’t be stacked on eggs and have excellent weight/cube mixes of products to ‘max out’ the loads,” says Dr. Schutt. The solution then creates the required signal for the TMS (transportation management system) to perform early tendering.

11. Supporting automation.

AI-enabled warehouse robotics technology can help warehouse operators increase the efficiency of picking operations.

“AI will help make voice picking technology more possible and prevalent. Through a headset microphone, a user can receive instant audio updates on inventory levels, supplier constraints, and order status,” says Sigler.

For example, Symbotic, a provider of AI-enabled robotics technology for the supply chain, offers robotic case pick capabilities that can help distributors serve retail customers.

Symbotic is implementing its robotic warehouse automation technology in Associated Food Stores’ Utah distribution center.

Associated Food Stores, a provider of groceries and other goods and services to independent retailers in nine Intermountain states, is deploying the AI-powered system to improve retail-facing operations, including picking and delivering products to stores.

12. Optimizing warehouse management systems.

Artificial intelligence can sit on top of a WMS and make it more responsive to an organization’s needs.

AutoScheduler.AI is one WMS accelerator that optimizes resources to improve operations. The software shows who is doing what, where, and when, and draws up plans to help facilities minimize travel, reduce touches, ship on time/in full, and drive labor efficiency.

Its dynamic warehouse plans are injected into the WMS to optimize activities based on constraints and enable sites to run optimally.

The AutoScheduler.AI platform was developed with P&G and implemented at P&G, Unilever, General Mills, and other companies.

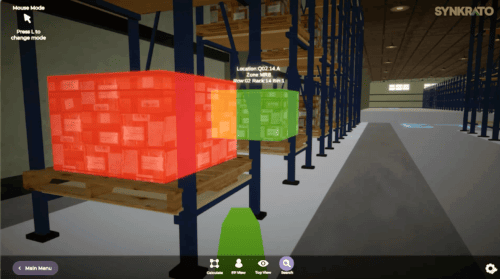

AI also supports advanced warehouse digital twin solutions such as Synkrato. The Synkrato Digital Twin integrates with the WMS, constantly ingesting data from multiple sources to create a real-time 3D representation of the warehouse.

13. Helping with quality control.

AI tools can monitor product quality throughout the supply chain. For example, Spinframe offers vehicle-inspection systems based on AI, computer vision, and machine learning technologies, that create digital twins for vehicles throughout the supply chain and detect anomalies from the assembly line to the dealership and end customer.

The Spinframe solution uses AI to identify defects and external damage. The platform can oversee a large number of vehicles without human intervention in various locations, such as ports, logistics hubs, parking lots, and service centers.

AI can also be trained to flag damaged products during the fulfillment process. Amazon has deployed AI at two fulfillment centers, with plans to add it to 10 more locations, to isolate faulty products before they are shipped to consumers, reports The Wall Street Journal.

The AI is integrated with imaging stations at Amazon’s fulfillment centers. Trained on product photos, the AI identifies any damaged items and diverts them to workers who will then double-check the products. With the damage rate estimated at fewer than one in 1,000 items, the AI solution allows workers to focus on their primary job of picking and packing orders.

14. Reducing equipment downtime.

AI’s ability to spot the rare, but costly, anomaly also applies to equipment used in the supply chain, from materials handling systems to tractor-trailers to railcars.

For instance, the Railcar Inspection Portal (RIP) solution from Duos Technologies, a provider of machine vision and AI that analyzes fast moving vehicles, rolled out its latest railcar AI detection model.

Leveraging this new algorithm, the RIP system can detect when a cushion unit head, which is similar to a shock absorber, is damaged or missing, so that it can be replaced before greater damage occurs, preventing potential derailments.

“AI will help with predictive maintenance. A generative AI assistant will keep tabs on equipment monitoring sensors and will give alerts when breakdowns will occur. It will also generate charts to show real-time equipment status and even contact technicians to schedule any larger repairs,” says Sigler.

15. Improving customer service.

The interactive, natural-language interface of AI is a fit for customer service.

“Using large language models (LLMs) allows sales reps to quickly learn more about shippers’ and carriers’ unique needs by identifying characteristics of their business,” says Alex Schwarm, head of data at Arrive Logistics. “These LLMs have vastly improved conversational interfaces, allowing less technical users to quickly get answers to basic questions, letting the data team focus on more complex work such as enhancing or developing new performance metrics to enable us to better serve customer needs.”

AI tools can also foster self-service. For instance, import shippers, especially smaller companies, can use a new, free AI tool from tech company eezyimport to identify import goods classification codes. The AI tool can convert text into the harmonized tariff schedule (HTS) code and provide tiered classification data based on suggestion algorithms. Users can enter specific product descriptions to improve accuracy; meanwhile, machine learning models continuously improve the algorithms.

16. Streamlining Customs clearance.

Aside from helping companies fill out customs paperwork, AI solutions can also streamline customs clearance processes.

For example, KlearNow.AI, a provider of customs clearance and drayage software, launched an artificial intelligence-powered platform, Customs Engine, to enable companies to move goods efficiently and compliantly through customs and ports.

The new software platform, targeted at importers, customs brokers, and forwarders, leverages five years of deep learning from its AI and machine learning data ingestion tool which created data sets for submission to customs authorities.

Customs Engine’s automated data extraction and document digitization capabilities can eliminate manual data entries and related errors. It generates Importer Security Filings and transmits them to customs authorities.

17. Processing ecommerce returns.

AI can attack reverse logistics challenges from multiple fronts. Using machine learning algorithms, companies can glean insights from their returns data and identify patterns and underlying causes.

Retailers can then make the adjustments needed—from revising product information on their website to tweaking packaging to changing shipping methods—that could lower the return rate.

In addition, AI can reduce product return rates by analyzing customer data and making personalized product recommendations.

Chatbots and virtual assistants can also help ecommerce customers through the returns process, taking on a large volume of customer inquiries and allowing human workers to focus on higher-value tasks.

Chatbots can learn from customer interactions, honing their responses to improve the efficiency of returns processes.

Lastly, machine algorithms could help companies determine the most efficient and cost-effective way to handle returns, taking into account brick-and-mortar locations, warehouses, shipping routes, and carrier performance.

18. Supporting sustainability initiatives.

AI-powered tools can cleanse and integrate data from disparate sources to facilitate carbon emission measurement and reporting.

One AI-enabled solution is BlueNode, which measures carbon and Scope 3 emissions from ports, terminal operators, maritime and rail carriers, shippers, and trade authorities.

Everstream Analytics recently acquired BlueNode to expand its intermodal analytics solutions and let users make data-based decisions on maritime carbon mitigation—balancing costs, shipping time, and environmental impact.

AI-based solutions can also enable more energy-efficient sea voyages, a recent trial found. Maritime technology company Yara Marine Technologies, AI application developer Molflow, and Chalmers University of Technology and social science specialists from Halmstad University and Gothenburg University in Sweden collaborated for more than three years to develop and trial an AI-based semi-autonomous voyage planning system.

The project showed how AI and machine learning can enable more energy-efficient voyage planning for ship operators. The results demonstrated successful energy efficiency optimization based on estimated time of arrival.

19. Increasing last-mile efficiencies.

“AI can help solve the famed last-mile problem with smart sensors on delivery vehicles, manual driver input, or location-based tracking,” says Hehman from TXI.

Its ability to process data and reduce human error can translate into huge opportunities for efficiency improvements in the last-mile space.

“Since moving products from a regional hub to a point of usage is usually the most expensive and challenging part of a supply chain, AI-enabled gains go a long way,” Hehman says. “By analyzing weather data, traffic patterns, and other environmental factors, an AI system can use data from smart sensors to ensure materials are delivered properly while optimizing the experience for the delivery person.”

20. Helping ensure worker safety.

By creating optimal routes, increasing efficiencies, and taking care of mundane tasks such as customs paperwork, AI can help boost worker satisfaction.

It can also flag potentially dangerous situations for human workers.

“AI can supplement human decision-making to ensure organizations are ensuring the health and safety of their employees,” says Hehman. “For example, a system can automatically send a message recalling delivery drivers when temperatures reach extreme highs or when environmental factors indicate tornadoes could form in the area.”