VERTICAL FOCUS: Electric Vehicles

Is the transition to an EV fleet right for your firm? Plus, the ABCs of electric vehicle batteries and delivery companies embrace EVs.

4 Tips to Transition to an EV Fleet

By: Jeff Wood, Senior Vice President, Operations, Wesco

By: Jeff Wood, Senior Vice President, Operations, Wesco

Supply chain professionals face several daunting challenges as they prepare to electrify their transportation fleet—from production delays to the development of charging hardware, vehicle load capacity considerations, vehicle range limits, and implementation of charging infrastructure.

As fleet managers look to navigate these challenges, here are four practical tips to support a seamless transition to electric vehicles.

1. Consolidate all operational data. Before starting out, make sure you have a full understanding of your fleet’s operational data. How much do you spend per month on fuel and maintenance? How many vehicles are nearing the end of their lifecycle? How many miles do your vehicles travel in a typical shift, and how many stops do they make? What kinds of jobs are they performing? Having all this data in one place tells a comprehensive story to isolate where and when EVs are the best option for your business and your customers.

2. Analyze sustainability goals and budget. How many vehicles will be cycled out annually and how much will this cost? What role will the total cost of ownership play? While EVs are generally more expensive, reduced spending on fuel and maintenance over time can outweigh the higher initial purchase cost. There are also tax credits or other government incentives on many EV models that could factor into budgeting decisions.

At the same time, analyze your company’s sustainability goals to determine how much of an impact this will make toward achieving those goals—and if the associated costs of doing so warrants the budget required to get there. It’s also important to factor in how new laws, such as California’s carbon emissions reporting legislation, might factor into the decisionmaking process.

3. Keep communication lines open among key stakeholders during the transition period. There is always a learning curve when an organization decides to implement EVs. It’s important to involve key stakeholders throughout the process to get buy-in and understand how operations may be impacted. Once deployed, fleet managers should keep in close contact with drivers, maintenance, and operations to understand how EVs are performing relative to initial goals.

4. Consider strategic partners to execute the transition process. Many fleet managers may not have the in-house resources to effectively manage the initial transition to EV fleets, especially if that requires adding charging infrastructure. External partners can provide value by helping fleet managers understand the full scope of the project, as well as any other needs that they may not have considered.

50,000+

Number of Tesla superchargers worldwide

15 minutes

Time it takes to recharge up to 200 miles

Need a Cab? Look Up

In October 2023, Boeing’s electric flying taxi company, Wisk Aero, became the first air taxi company to hold public electric vertical takeoff and landing (eVTOL) demonstration flights at the Long Beach Airport.

The demo, using Wisk’s 5th gen eVTOL, allowed the company to run an autonomous flight alongside other passenger airlines in a complex, real-life situation.

ABCs of EV Batteries

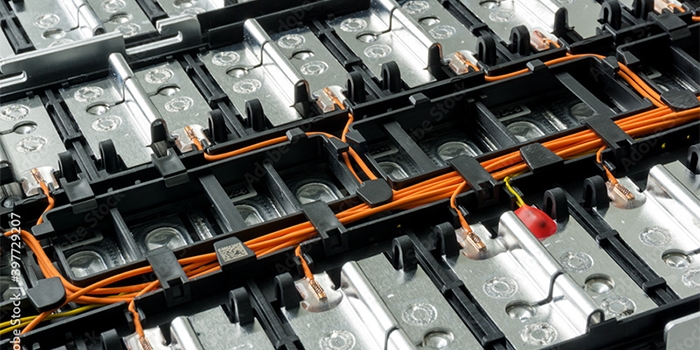

Electric vehicle (EV) batteries power electric cars the same way gas powers internal combustion engined cars. Electric vehicles get all their power directly from a pack of batteries, typically placed under the floor in the center of the vehicle. Rather than a single battery, EV batteries use a pack comprised of thousands of individual Li-ion cells that work together.

Unlike batteries in most vehicles, which are primarily used to run accessories or start the engine, EV batteries run everything. They need to be powerful and long-lasting enough to take drivers to their destination while keeping the need to recharge to a minimum.

How do EV batteries work? When a truck or car is charging, electrical energy is routed to the battery system, resulting in chemical changes inside the battery pack that effectively store that energy for subsequent use.

While someone drives an EV, however, these chemical changes are reversed in order to release an electrical current to power the motors in the EV’s wheels. When a driver steps on the accelerator, the EV immediately feeds power to the motors, which gradually consume the power in the batteries.

How are EV batteries made? EV batteries are made using a combination of base metals and rare earth elements such as lithium, manganese, nickel, cobalt, aluminum, iron, and other elements including carbon or graphite. These elements are combined with electrolytes to produce an electric current that each cell of the battery systems generates.

Battery cells are wired together to generate the necessary voltage and amperage to power the vehicle’s motors and generate motion.

Approximately 80% of the components are recyclable, so when batteries reach the end of their lifecycle, they can be stripped down and their parts can be reused.

Transport Companies Charge Ahead

Transportation and logistics companies continue to incorporate electric trucks into their fleets for several reasons: to reduce their environmental impact and meet increasing customer demand for sustainable transportation, and reduce fuel and maintenance costs.

Among the leading transportation companies to implement electric trucks are:

- Amazon has partnered with Rivian to develop and deploy electric delivery vans. The company has already begun to take delivery of these vans and plans to have 100,000 electric vans in its fleet by 2030.

- FedEx has partnered with BrightDrop, a subsidiary of General Motors, to develop and deploy electric delivery vans. The company has already taken delivery of 150 BrightDrop Zevo 600 vans and plans to have 2,500 electric vans in its fleet by 2025.

- UPS has partnered with Arrival to develop and deploy electric delivery vans. The company has already placed an order for 10,000 Arrival vans and plans to have 25,000 electric vans in its fleet by 2025.

- BrightDrop is a subsidiary of General Motors that is developing and deploying electric delivery vans and trucks. The company has already partnered with FedEx and Walmart to deploy its vehicles.

- DHL has partnered with a number of companies to develop and deploy electric trucks and vans. The company has already deployed thousands of electric vehicles and plans to have 80,000 electric vehicles in its fleet by 2030.