News & Trends Impacting the Auto Supply Chain

Auto Tariffs: U.S. Pays The Price

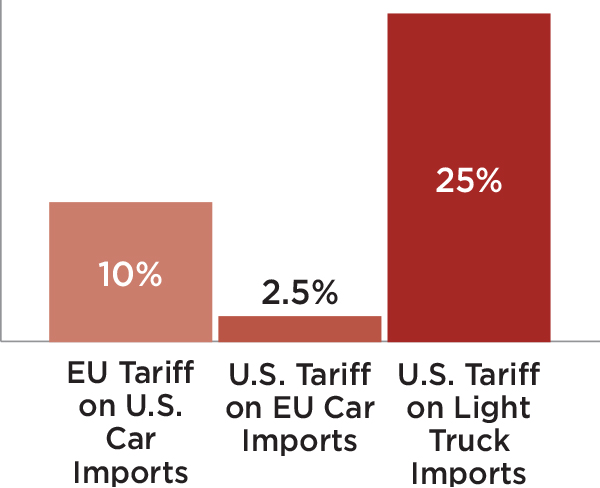

Citing a “big trade imbalance,” President Trump has threatened to place a tax on vehicles imported into the United States from Europe. In fact, such a tax already exists—a relic from a trade war fought in the 1950s. Consumers already absorb a 2.5-percent tariff on cars and a whopping 25-percent tariff on light trucks imported into the United States.

Spotting A Fake

German automotive products companies are using a cloud-based, track-and-trace solution from Honeywell to detect counterfeit products globally.

Honeywell collaborated with automotive aftermarket provider TecAlliance to develop the oneIDentity+ service platform, which authenticates and tracks individual components for major auto parts manufacturers. The platform assigns each component a specific digital ID label that users can track with a mobile device from at any point—whether it is loaded onto a truck, unloaded at a distribution center, or shipped to an end user.

“No One Wins A Trade War”

“More tariffs won’t help American businesses or families. Tariffs are taxes, and the result will be more expensive vehicles—effectively erasing any positive change Americans saw from the 2018 tax reform bill. Auto sales, which are already slowing, will be hamstrung by these tariffs. America’s 2,500 European branded dealerships and their 175,000 employees will be less competitive. The resulting trade war will undoubtedly spread to include other industries, including American agriculture. No one wins a trade war.”

— American International Automobile Dealers

Association President and CEO Cody Lusk

regarding a brewing trade conflict

with the European Union

Inbound Supply Best Practices

Automotive suppliers should have in place the following critical supply chain capabilities and activities to comply with customer contract requirements and execute perfect supply fulfillment:

- Lean manufacturing and logistics practices.

- Replenishment processes, procedures, and policies that ensure high-quality, low-cost, on-time deliveries throughout the extended supply chain.

- Electronic communication between suppliers and customers (zero latency preferred).

- Demand analytics around EDI transaction sets 830, 862, 866, as well as any web-based electronic communication.

- Real time collaborative communication throughout the supply chain to address potential issues in meeting demand requirements.

- Ability to react to weekly schedule variation, comparing demand to capacity.

- Ship according to a latest set of transportation routing instructions.

- Real-time response to alerts, issues, and exceptions.

- Repeatable processes that minimize human intervention including continuous process measurement and reporting.

- Weekly or monthly identification and measurement of key trending metrics, with corrective action planning to address metrics that don’t meet goals.

— One Network Enterprises