Reducing Customer Costs Through Strategic Inventory Movements

The supply chain presents a considerable, albeit unavoidable, cost to companies. Efficient operations with a proactive logistics partner are vital in allowing companies to maintain a balance between this expense and the final cost of product.

At Taylored, customer Quarterly Business Reviews outline current performance and identify areas of opportunity through case studies. In this case study, our customer is a parent company and two of its subsidiaries that sell both direct to consumer and wholesale.

Traditionally, one-third of total spend is on inventory costs. Having risen above that threshold, our customer care team took actions to evaluate and provide recommendations. After analyzing the current operation, the team determined both pallet consolidation and strategic inventory movement changes would significantly reduce costs.

Although the two subsidiaries operate independently, inventory is often cross-transferred. These transfers are done based on exact inventory demand, prompting moves of partial cases between physical locations. These movements involve multiple touch points after initial warehousing because it is common to transfer the same product multiple times. In addition to repeated inventory movement costs, there is a significant reduction in location efficiency. The customer care team found that solely by consolidating pallets, the company would free 587 locations with a weekly cost savings of $2,348.

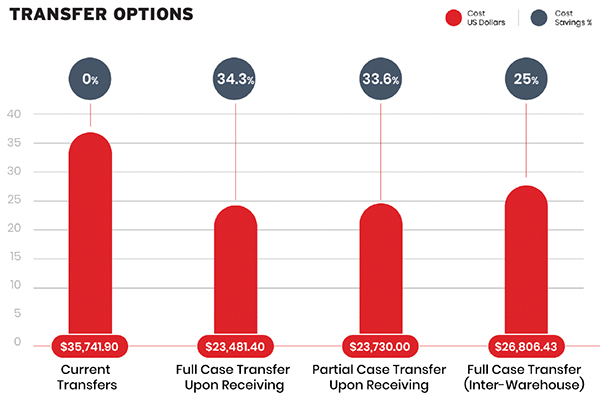

The team also presented the customer with three options to better strategize their inventory transfers. The most desirable solution involved transferring inventory at the full case level upon receipt into the facility. Instead of warehousing product and transferring at a later date, inventory would go directly to the new location and reduce customer spend by 34.3%. A second possibility is transferring partial cases upon receipt. This option allows the customer more flexibility to respond to exact inventory demands, but decreases the cost savings to 33.61%.

A final potential solution presented to the customer was less impactful, but implied fewer changes to their current operation. Transferring only full cases between companies, instead of partial cases, resulted in a cost savings of 25% in comparison with their current strategy. The team also recommended the company analyze the possibility of arranging these transfers internally before arrival at the warehouse facility as a viable option for further cost reduction.

This case study is an excellent example of Taylored’s commitment to customer success. Our Customer Care team is experienced in both operations and sales, giving them a unique perspective and ability to bridge different challenges that customers face. Their unique approach allows them to develop independent processes designed to drive the success of their customers through increased operational transparency and strategy.

tayloredservices.com

732-750-9000

[email protected]