Reshaping the Supply Chain: How New Strategies, Goals & Technologies are Altering Supply Chain Operations

Picture trucking in the United States minus interstate highways. Global trade without shipping containers. Supply chain management with no internet.

Businesses once managed without those innovations, but it’s hard now to understand how they did it. That kind of evolution never stops. Today’s novelties in logistics technology and strategy will soon become tomorrow’s commonplace tools of the trade. Here are some examples.

Practical Tips for Supply Chain Digitization

Uber-like Platforms for Freight?

1. More Freight, Less Waste

Some paradigm shifts will involve optimizing transportation assets to reduce waste in the supply chain.

When trucks drive deadhead miles, or drivers sit around waiting for loads, or tractor-trailers crawl in heavy urban traffic, those underused assets create waste in the supply chain.

Waste hurts the bottom line.

That’s why some upcoming paradigm shifts involve ways to make better use of transportation assets.

At Class I railroad Kansas City Southern (KCS), for instance, strategists expect to see self-driving trucks form platoons to haul intermodal containers from rail terminals to large distribution centers or industrial parks. In this vision, perhaps four autonomous trucks will follow one rig driven by a human.

“You have one driver, but five loads,” says Brian Hancock, executive vice president and chief innovation officer at KCS in Kansas City, Missouri. That increases efficiency right off the bat, reducing the number of scarce and costly resources—drivers—needed to deliver five containers.

Platoons would travel late at night, taking better advantage of another resource: highway capacity. “One of the most underutilized assets in the country is the freeway system around our big urban populations between 10 p.m. and 5 a.m.,” says Hancock.

Drivers would no longer struggle with rush hour traffic and construction slowdowns. Instead, multi-truck platoons would zip along nearly empty lanes overnight, completing deliveries faster.

So why use a driver at all? When autonomous trucks hit the market, couldn’t a platoon’s lead truck drive itself, just like the other four?

“We’re not big into having that much freight out there without a driver,” Hancock says. It takes a human to manage liability for the platoon and keep the shipment secure.

Of course, this strategy works only if trains arrive at terminals in time for platoons to pick up containers and deliver them as promised. That didn’t seem possible in the past. But with the advent of precision scheduling, railroads have been improving their on-time performance, making overnight platooning feasible.

If this innovation can take thousands of trucks off the road during peak traffic hours, cut transportation costs by using fewer drivers, and speed containers to their destinations, then intermodal becomes more attractive, Hancock says. That would add a further efficiency: letting more shippers enjoy the cost benefits of intermodal transportation.

DRAYAGE GETS SMART

New drayage technology minimizes driver wait time, gets trucks in and out of the port faster, and increases freight visibility for shippers.”

For international shipments, much of the waste occurs when trucks arrive at ports to retrieve containers. It takes a lot of manual labor, with many visits to a port’s website, to learn when a container is ready for pickup.

Lacking good visibility, a drayage driver may spend hours waiting at the port for a container that’s sitting at the bottom of a stack, with no container handling equipment nearby. Or a container might sit in the yard waiting for the assigned driver to arrive.

“As containers sit in the port for longer than the free time a shipper has with the ocean carrier, costs go up,” says Ed Summers, senior product manager at New York-based Loadsmart. Summers leads the team responsible for a new product from Loadsmart called Smart Drayage, which seeks to change the paradigm for container pickups.

Today, when a company with 20 inbound containers on the same ship arranges for drayage, each driver is assigned a particular container. If that box isn’t ready when the truck arrives, the driver waits in the terminal.

Under the Smart Drayage model, the company tenders the shipment to Loadsmart, which dispatches carriers to the port. When drivers reach the gate, instead of saying they are there for a specific container, they say they are there to pick up one of the containers in the group.

“The port knows where all their containers and equipment are, thanks to the terminal operating systems that provide high levels of visibility,” Summers says. Through an interface to that logistics technology, the Smart Drayage platform determines which containers are easily available for pickup.

“For example, we know that container CDE is at the top of the stack, and it’s 50 feet away from a crane that can service it,” Summers says. The driver goes to that location, quickly retrieves the container, and gets back on the road. Consignees get their freight faster, and shippers are less likely to incur storage charges at the port.

To sweeten the deal for carriers, Loadsmart has arranged for a dedicated Smart Drayage gate at the terminal. Because the system gets them in and out of the port faster, truckers also gain the chance to make more runs in a single day.

Thanks to integration with the terminal system and with several brands of electronic logging devices, Loadsmart increases visibility for shippers, providing updates on the status of their containers, both in the yard and in transit.

Smart Drayage currently operates at the Port of New York and New Jersey. Loadsmart hopes to bring it to other ports as well, Summers says.

SUSTAINABLE SUPPLY CHAINS

For many companies, delivering value to customers includes a commitment to protect the earth.

The paradigm of profit over everything else has started to shift in the business world, according to some corporate leaders. In August 2019, 181 CEOs of major U.S. corporations, members of a group called the Business Roundtable, signed a statement declaring that rather than simply maximizing profits, American businesses should aim to invest in employees, deliver value to customers, deal ethically with suppliers, and support outside communities, according to a CNBC report.

For many firms, delivering value to customers includes a commitment to protect the earth. Eighty-one percent of people responding to a 2019 Nielsen global survey say they feel strongly that companies should help to improve the environment (see chart below).

In response, business leaders have promised to make reforms, such as reducing their use of non-recycled plastics. “A lot of the filings by most of these companies have clearly stated sustainability goals and measured against those goals,” says Madhav Durbha, group vice president of industry strategy at supply chain software company LLamasoft in Ann Arbor, Michigan.

Some sustainability initiatives involve relatively simple changes in supply chain strategies, such as optimizing freight routes to reduce empty miles, postponing production to better match demand and avoid throwing out excess inventory, and shipping products in smaller packages. Other steps require longer-range planning.

For example, Costco has switched from round to square-shaped containers for products such as nuts, letting it pack more units in a truck. “That requires collaboration between research and development and the logistics organization to make sure the packaging can take the load,” Durbha says.

Procter & Gamble (P&G) has launched a product line called DS3, which reduces hand soap, laundry detergent, and other cleaners to small, dry swatches that foam up when the user adds water. By minimizing water in the product, P&G vastly reduces the bulk it must ship, thus cutting the number of trucks it puts on the road. “It provides a ton of efficiencies, reducing not just the carbon footprint but also the water footprint,” Durbha says.

Some LLamasoft customers use the company’s supply chain planning software to promote sustainability along with other business goals. “Instead of modeling to optimize profit, revenue, service, or inventory, companies can explicitly model their carbon footprint optimization,” Durbha says.

Full Circle

Making products from recycled materials is just a Band-Aid. The real problem is disposability and single use.

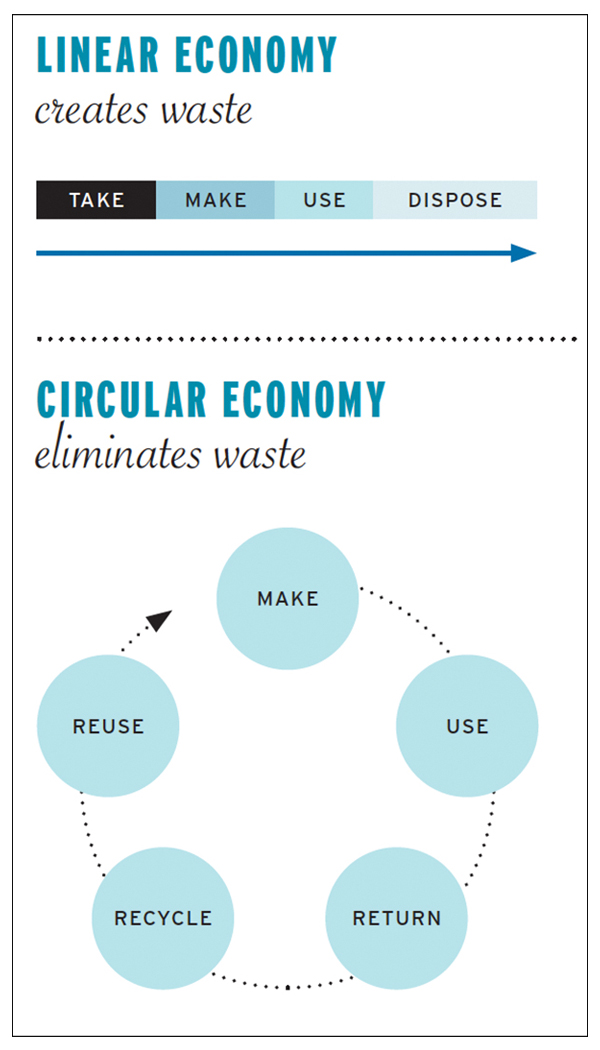

The shape of things to come in supply chain responsibility is round, according to business advisory company Gartner. By 2029, today’s linear economy will transform into a circular one, which will “encourage the continuous reuse of materials to minimize waste and demand for additional natural resource consumption,” the company says.

That circular metaphor clearly resonates with TerraCycle, a Trenton, New Jersey-based firm that chose the name “Loop” for a new enterprise to promote reusable packaging.

TerraCycle began its business by collecting and recycling materials—such as flexible plastics and cigarette butts—for which municipal recycling programs don’t have markets. It then started retrieving discarded plastic from beaches for companies to turn into packaging. P&G, for instance, works with TerraCycle to make Head & Shoulders shampoo bottles from beach plastic.

TerraCycle has gotten Colgate, Tide, Häagen-Dazs, Hellmann’s, and many other brands to produce special reusable containers for Loop. Consumers order products from those brands through Loop’s e-commerce site. UPS delivers a customer’s order in a Loop-branded tote. The customer uses the products and then tucks the empties into the tote for shipment back to Loop.

“Loop receives those dirty, empty packages and cleans and sanitizes them,” says Tony Rossi, vice president, global business development at Loop. “Then we send them back to the brand to be refilled and re-enter inventory.”

Starting in 2020, customers will also be able to buy Loop products at Kroger and Walgreens stores and return the packaging there.

In the United States, Loop operates in 10 Northeastern states. The company also runs the service in parts of Europe.

Loop was born after TerraCycle CEO Tom Szaky concluded that making products from recycled materials won’t, on its own, solve the sustainability challenge. “While that’s important, it’s just a Band-Aid,” Rossi says. “The real problem is disposability and single use. Materials become waste too quickly. We have to stop items from becoming waste to begin with.”

2. Digital Transformation

Some of the biggest shifts in the supply chain world are emerging from advanced digital technologies. Thanks to artificial intelligence (AI), data analytics, the Internet of Things (IoT), blockchain, and other innovations, companies are using digitization to gain business insights that were never available before, and to collaborate at a level that wasn’t possible in the past.

Companies are using digitization to gain business insights that were never available before.

For example, in November 2019, Walmart Canada announced a new blockchain solution that lets it share data and collaborate with 70 trucking carriers.

Customers of Aera Technology use AI to automate what used to be largely manual processes and to augment their ability to make supply chain decisions. Drawing data from an order management system, a warehouse management system, and others, Aera’s solution can, for example, prioritize fulfillment for hundreds of thousands of orders, based on established rules.

When setting priorities, this logistics technology considers much more than which are the biggest customers. “It also looks at volumes you need to ship, profitability, current inventory, service, and fines you would have to pay versus the cost you incur to provide that service to that client,” says Kaushal Dave, executive vice president and global head of digital supply chain products and customer engagement at Aera in Mountain View, California.

The system can also respond to exceptions, recommending changes in the fulfillment sequence while avoiding risks such as out-of-stocks and back orders.

“It has to look at hundreds of different data points, which is not humanly possible for the people who were doing this,” says Dave. Besides making recommendations based on current conditions, the system looks ahead to make sure that a decision in the present won’t cause problems in the future.

For instance, “It constantly predicts the volatility of orders for the next six months based on demand,” he says.

LiveSource, a technology provider based in Atlanta, uses AI in its supplier management solution. For instance, a LiveSource customer might use this tool to analyze thousands of transactions with thousands of contract manufacturers, looking for patterns that indicate incipient problems.

Irregularities such as quality issues or incomplete deliveries might fly under the radar if a company does only a little business with a particular supplier, says Bo Hagler, CEO at LiveSource. But with greater volume, those issues might become significant. Better insight into trends could dissuade you from awarding that supplier more business.

“You cannot reach that decision by just taking a snapshot of the performance based on the way you evaluate it,” Hagler says. “You have to look at what’s happening across multiple categories.”

IoT devices can provide new sources of data for making those decisions. Some manufacturers that work with LiveSource attach sensors to industrial molds—large machines worth upward of $500,000 that they own, but their suppliers operate.

“Putting IoT devices on that technology enables them to see when the equipment ran and how often,” says Hagler. “They can see, based on how much it ran, how many parts it could have produced versus how many they actually received.”

Applying analytics to that data, a company might identify problems with efficiency or wasted materials, or even learn that the supplier is using the mold to produce product for other customers.

3. Brilliant Collaboration

Advanced digital technologies such as AI, blockchain, and IoT play starring roles in the IBM Sterling Supply Chain Suite, a new solution IBM introduced in October 2019. The suite lets companies collaborate with trading partners on the 800,000-member Sterling B2B Network while gaining views into their operations that weren’t possible without digitization.

Artificial intelligence capabilities can reveal imbalances between demand and supply before they cause problems.

For example, for manufacturers that build to order rather than to stock, Sterling’s AI capabilities can reveal imbalances between demand and supply before they cause problems. “Any risk or variation to inbound supply could be incredibly disruptive to production and meeting sales orders,” says Jeanette Barlow, vice president, product management, supply chain at IBM Sterling in Boston.

A system driven by AI can detect small anomalies in the inbound flow of materials or components, perhaps a weather delay or a hiccup at customs. It can predict how those events will affect production and order fulfillment days in advance and then recommend mitigation strategies, such as adjusting order fulfillment plans or tapping alternative sources for materials.

Blockchain creates a ledger where many parties involved in a supply chain—including trading partners and service providers—can access a common pool of data, providing one shared source of truth and ensuring that everyone who needs certain information will receive it. Access is based on permissions, so each participant sees only the data needed to perform its role.

Data in the blockchain could include IoT sensor data. Data from documents tells participants where cargo is supposed to be; sensor data tells where it really is; and, in a temperature-controlled shipment, temperature sensors report on the load’s condition.

“You can get an incredibly powerful view of your supply chain shared among your key participants,” Barlow says. Then, if an exception occurs, AI will detect it and alert everyone concerned to the possible consequences.

Innovations of this sort may stand on the cutting edge of supply chain practice right now. But in a few years, it could be hard to understand how anyone did business without them.

Practical Tips for Supply Chain Digitization

As you launch an initiative to transform your supply chain operations through digitization, here’s some advice to keep in mind:

Standardize your data, advises Bo Hagler, CEO at LiveSource, an Atlanta-based firm that provides a cloud-based supplier management system.

Too often, companies store essential data in disparate systems and spreadsheets, with many inconsistencies and redundancies. Enforce standards, and you can start making apples-to-apples comparisons.

“Then you can start getting some amazing things from artificial intelligence (AI),” Hagler says.

“Start small and build on success,” he adds . Don’t try to use data analytics to embrace all your opportunities for improvement at once. Rather, define the minimum data you need to support a specific solution, create and test that solution, and then move on to the next thing.

Try to solve one problem at the outset—or maybe three, but no more, says Jeanette Barlow, vice president, product management, supply chain at IBM Sterling in Boston.

Don’t deploy AI or another advanced technology for its own sake; use it as a tool toward a specific business goal. “It’s critical that the technology is rooted in a business outcome that is meaningful and measurable,” Barlow says.

Change your processes, not your underlying IT systems, says Kaushal Dave, executive vice president and global head of digital supply chain products and customer engagement at Aera Technology in Mountain View, California.

Replacing your WMS, TMS, ERP, or other systems can take years, cost a fortune, and not really change the way you do things. Better to implement advanced technologies on top of those systems.

Then, for example, instead of prioritizing orders by customer, you can make decisions based on data pulled from several systems. “It’s looking at customers, volumes, lead times, service, inventory, costs, fines—everything you did not look at before,” Dave says.

Uber-like Platforms for Freight?

What if finding a trucker to move your freight could be as simple as summoning a ride share?

Ride-hailing market leader Uber is among the growing number of companies to introduce automated online marketplaces for truck freight: It launched its Uber Freight business, based in Chicago, in 2017. A competing service, Seattle-based Convoy, recently added $400 million to its funding, bringing the company’s valuation to $2.75 billion.

Others are also vying to attract shippers and carriers to their freight matching platforms. One is Loadsmart, which offers shippers capacity for full truckload shipments. Using application programming interfaces, Loadsmart feeds its listings into a shipper’s transportation management system.

“Rather than having to call each carrier to find out if they’re available, and if they’ll take the load for a price, we show availability and a real-time price that’s instantly bookable,” explains Zach Fredericks, business development executive at Loadsmart.

Carriers go through a vetting process before joining Loadsmart’s network. Shippers can also tailor the assortment of carriers they see through the logistics technology platform. “If there are certain specifications they’re after, we can accommodate that,” Fredericks says.

New York-based Transfix is a tech-enabled full truckload broker that lets shippers secure capacity on the spot market, but also helps match shippers and carriers for long-term contracts for dedicated service. Its technology includes a set of pricing algorithms designed to keep carriers and shippers happy with the rates they agree on over the term of their relationship.

“We use millions of data points to constantly input and refine what we believe our contract pricing will be,” says Marissa Ash, head of sales at Transfix. “Our shippers have confidence that they’re getting the most market-competitive price, and that we’ll hold that for the time they need us to.”