Georgia: Logistics Sweet Spot

Many elements make The Peach State appealing to site selection teams. But the seeds of its success are firmly planted in its logistics assets.

Ray Charles may have put Georgia on everyone’s mind, but when it comes to manufacturing and distribution site selection, it is the state’s ships, planes, trains, and trucks that keep Georgia top of mind.

“Georgia is so fortunate to have tremendous logistical advantages—combined with a central geographic location, highly skilled workforce, and business-friendly environment,” said Chris Carr when he was named commissioner of Georgia’sDepartment of Economic Development in 2013. “In the three years since Governor Nathan Deal took office, Georgia successfully attracted more than 75,000 new jobs and $14 billion in investment to the state. As the old saying goes: ‘If it ain’t broke, don’t fix it.'”

While there may be nothing to fix, somehow the state still finds new ways to solidify and improve its position of logistics leadership.

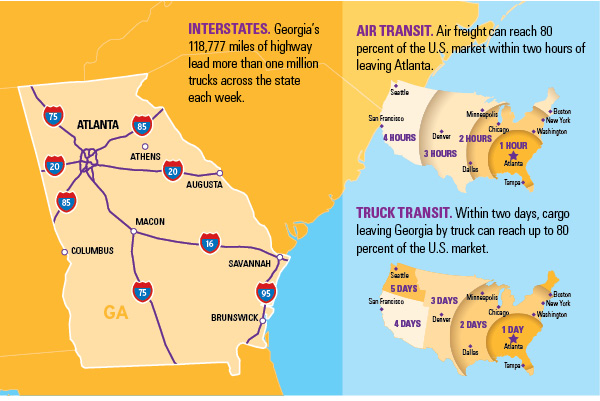

Third-party logistics (3PL) providers and transportation companies in Georgia gain competitive efficiencies and strategic business advantages by operating in the transportation “super hub” of the Southeast. Locating operations at the crossroads of north-south and east-west travel in North America enables them to move products quickly and easily via air, road, rail, and sea to global markets in the Americas, Europe, and Asia.

Four of the top 10 warehouse providers in North America are headquartered in Georgia, and 90 percent of the top 25 global 3PLs maintain operations in the state. Tier 1 companies leverage Georgia’s 4,700 miles of railway, 118,777 miles of top-ranked public highways, the world’s busiest and most efficient airport, and two deepwater seaports to connect with customers.

This built-in logistics ecosystem fuels competitiveness throughout the state, and provides a solid foundation for sustainable growth. Businesses save time and money by seamlessly connecting airports and seaports with rail and roads, enabling companies to compress shipping and delivery cycles.

PROGRESS AT THE PORTS

Central to Georgia’s role as a logistics leader are the activities of the Georgia Ports Authority (GPA). The organization is committed to maintaining the state’s competitive edge by developing leading-edge technology, marketing, and operations to move cargo faster. In addition, the GPA works to identify what must be done today to sustain growth, performance, and security tomorrow.

“Since 1945, Georgia’s ports have served as magnets for international trade and investment, enriching the state’s economy,” says GPA Executive Director Curtis Foltz. “The Georgia Ports Authority is dedicated to providing customers with the most efficient, productive port facilities in the nation, and to creating jobs and business opportunities to benefit more than 9.1 million Georgians.”

GATEWAYS TO THE WORLD

Georgia’s deepwater ports in Savannah and Brunswick—together with inland barge operations in Bainbridge and Columbus—are the state’s gateways to the world. “Ports are the critical conduits through which raw materials and finished products flow to and from destinations around the globe,” Foltz says.

As a quasi-state agency, GPA activities are governed by a 13-member board of directors appointed by the governor to serve staggered four-year terms. As chief executive, Foltz implements policy directives, administrative duties, and managerial controls.

One of the state’s largest public employers, the GPA directly employs nearly 1,000 trained logistics professionals. GPA operations—together with private sector, port-related operations—account for some 352,000 jobs statewide, $66.9 billion in sales, and income exceeding $18.5 billion annually.

Georgia’s port operations include:

-

- The Port of Savannah. Two modern, deepwater terminals—Garden City Terminal and Ocean Terminal—comprise the Port of Savannah. Together, these facilities exemplify the GPA’s exacting efficiency and productivity standards.

At 1,200 acres, the Garden City Terminal is the nation’s largest container facility. Because the entire terminal is owner-operated, the port’s operations are streamlined to serve shippers and carriers.

At some other ports, for example, truckers must check in to one shipping line’s leased terminal to drop off an export box, then repeat that check-in process at another line’s terminal to pick up an import box. At Garden City Terminal, however, truckers check in once, navigate to drop-off and pick-up points, and enjoy much quicker turn times.

By the same token, Garden City features nearly 10,000 feet of berth space that is offered on a first-come, first-served basis. Ships don’t have to wait on a limited number of berths leased to a specific company. As a result, both maritime and landside port users can get cargo moving more quickly and efficiently.

Savannah’s dedicated breakbulk and roll-on/roll-off facility, Ocean Terminal, covers 208 acres and provides customers with more than 1.3 million square feet of covered, versatile storage.

- The Port of Brunswick. Composed of three GPA-owned deepwater terminals, the Port of Brunswick is one of the fastest-growing auto and heavy machinery ports in North America. More than 20 major auto manufacturers, supported by five auto processors, use the Colonel’s Island Terminal, which is also home to the Southeast’s fastest-growing bulk export/import operation. Agri-products from Georgia and the U.S. grain belt, as well as import products, flow smoothly across the Colonel’s Island docks.

The Port of Brunswick’s Mayor’s Point Terminal facilitates exporting Georgia’s valuable forest products, while Marine Port Terminal specializes in handling breakbulk and bulk commodities. - Port Bainbridge and Port Columbus. Georgia’s inland terminal operations provide a strategic advantage for bulk commodities moving to and from the southeastern United States.

An important facet of the GPA’s success is Georgia’s geographical advantage. “The Port of Savannah’s location makes it a hub for the export of American-made products from cities such as Atlanta, Birmingham, Memphis, Louisville, and Charlotte,” explains Foltz.

Another location-related advantage: room to grow. “While Georgia’s ports currently handle about three million 20-foot equivalent container units (TEUs) annually, the GPA’s strategic plans will allow us to handle 6.5 million TEUs without increasing our physical footprint on terminal,” Foltz says. “Off terminal, a wealth of industrial real estate near the port and major interstates is available for development.”

Further competitive assets include interstate access, two Class I rail lines, and the largest portfolio of containership services in the U.S. Southeast. Immediate access from the Port of Savannah to I-16 heading east-west, and I-95 stretching north-south, means motor carriers can reach key cities and manufacturing points throughout the U.S. Southeast and Midwest within a one- to two-day drive.

Thanks to on-terminal rail yards, cargo shipped by rail is not limited by highway weight restrictions. Service from both Norfolk Southern and CSX Transportation delivers more choices for reaching the hinterlands.

With 5.4 million people in the Metro Atlanta area, and a state population of 9.9 million, Georgia is more than a formidable singular market. Its transportation infrastructure makes it a springboard to reach the entire U.S. Southeast.

SHIP TO RAIL

Rail connectivity from the Port of Savannah means cargo owners enjoy daily service to every major destination east of the Mississippi. GPA’s Network Georgia provides the fastest rail connections of any East Coast port to Alabama, Tennessee, Louisiana, and Texas, as well as overnight service to Atlanta, Charlotte, Jacksonville, and Charleston.

“The Port of Savannah is 100 miles closer to Atlanta than any other port,” Foltz notes. “This is significant because Atlanta serves as a major hub for rail and truck traffic.”

As the only East Coast port featuring two Class I rail providers on a single terminal, Savannah offers two-day service to Birmingham and Huntsville, Ala.; Miami, Orlando, and Tampa, Fla.; and Memphis and Nashville, Tenn. Norfolk Southern and CSX service at the Port of Savannah’s Garden City Terminal averages 18 inbound and 18 outbound trains weekly, delivering more choices to reach inland markets.

“Our two on-terminal intermodal facilities also mean shippers don’t have to haul their goods to remote rail yards, and can get cargo to DCs or other destinations more quickly,” Foltz says. “What’s more, fewer truck miles mean shorter transit times, resulting in improved speed to market and lower storage costs.”

Superior infrastructure at the GPA is matched by more flexible service. “In the past, many shippers equated intermodal directly to rail. But today, the GPA focuses on how intermodal moves fit into the port’s overall efficiency,” says Griff Lynch, the GPA’s chief operating officer. “The current view encompasses the whole process from ship to destination, and beyond. It includes establishing routes before a container is even shipped.”

The 30 employees who coordinate the movement of cargo to and from GPA rail yards are now also part of a larger and more flexible group that includes all of operations. Developed over the past few years, this operations strategy allows the GPA to absorb increased volume in different sections of the terminal, with the flexibility to move skilled workers to where they are most required at the time.

“Savannah serves as the Southeast’s hub for intermodal moves,” says John Trent, the GPA’s senior director of strategic operations and safety. “The port is working with its two Class I railroads to strengthen its position, and make Georgia the dominant hub for East Coast rail traffic.”

An inland port agreement signed by the governor, the GPA, and rail access provider Cordele Intermodal Services extends the international reach of businesses in Southeast Georgia and adjacent regions of Florida and Alabama by ensuring a direct 200-mile rail route to and from GPA’s Garden City Terminal in Savannah.

The Port of Savannah forms a distribution center hub, with more than four million square feet of warehouse space available. “Attracting DCs to the port will generate vessel calls to serve those facilities,” says Foltz. “In turn, those calls guarantee more empty container deliveries to support the region’s export market.”

The Port of Savannah has garnered keen interest among many national 3PLs, prompting them to establish facilities to help serve shippers more efficiently.

“Adding to that momentum was a change in the business model of large retailers,” says Stacy Watson, the GPA’s general manager of economic and industrial development. “To concentrate on their core business, many big-box retailers outsourced logistics operations.”

As big-box retailers locate distribution centers in Georgia, they bring their 3PLs with them. This development created a boom in Savannah’s 3PL market, and gave the GPA access to shippers served by 3PLs in other cities.

A key factor in 3PLs selecting the Port of Savannah is the volume of ocean shipping services—which gives shippers more solutions to meet their logistics needs.

“Georgia’s growth and prosperity are inextricably linked to the success of its ports, and to the state’s ability to complement them with the best surface logistics network in the nation.”—Jay Shaw, Chairman, State Transportation Board

“Savannah has more weekly container services than any other port on the East Coast except for New York,” says Chris Logan, the GPA’s senior director for trade development. “The number of ocean services offers 3PL customers more choices for reaching world markets.”

The Georgia Ports Authority is also making significant investments in terminal improvements to increase capacity and boost efficiency—further establishing Georgia as the gateway for trade to the southeast United States. Among the GPA’s growth initiatives:

New cranes. Four new ship-to-shore cranes at the Port of Savannah’s Garden City Terminal bring the number of electric-powered container cranes to 27—the most at any single terminal in the United States. “These new super post-Panamax cranes further enhance the terminal’s cargo handling efficiency,” says Foltz.

The new cranes help prepare Savannah to better accommodate larger container vessels, expected to increase in number after the expanded Panama Canal opens in 2015.

New roads. Also aiding faster cargo movement is the Jimmy Deloach Parkway extension, which will provide a direct link between Interstate 95 and the Port of Savannah. The Georgia Department of Transportation has broken ground on the project, and expects to complete the 3.1-mile, $72.8-million connector in May 2016. The project will cut 11 minutes from the drive time for vehicles traveling State Road 21 and the Jimmy Deloach Connector.

“The Deloach Connector illustrates the unprecedented level of cooperation and collaboration between Governor Deal, the Transportation and Ports Authority boards, and the Georgia Department of Transportation,” says State Transportation Board Chairman Jay Shaw. “Georgia’s growth and prosperity are inextricably linked to the success of its ports, and to the state’s ability to complement them with the best surface logistics network in the nation.”

A recently completed overpass on Georgia Highway 307—the main truck route into Garden City Terminal—will also provide better connections for surface transport. The overpass is one of the final steps in a cargo beltway linking the Port of Savannah to the Southeast by way of interstates I-16 and I-95.

The overpass will expedite traffic into the GPA’s Garden City Terminal, which handles nearly 8,000 truck moves a day. Through its road and rail connections, the Port of Savannah serves 18 major retail distribution centers, encompassing more than 15 million square feet of space.

“This $22.5-million investment shows the state’s commitment to improved cargo movement beyond the terminal gates,” Foltz says.

Rail improvements. The Highway 307 overpass complements a $6.5-million six-track rail yard expansion. Norfolk Southern, the Georgia Department of Transportation, and the GPA worked in tandem on the overpass and rail expansion projects to boost efficiency for both truck and rail transport. The overpass routes trucks above the one previous rail line and the six expanded tracks at the Port of Savannah’s Mason Intermodal Container Transfer Facility.

CSX Transportation has also made significant investments to improve efficiency at Garden City Terminal, including a $5-million track upgrade, which expedites container movement in and out of the facility.

“Combined with other recent improvements, this expansion will reduce Savannah-Atlanta round-trip rail transit by six hours,” says Lynch. “The efficiency gains for each container will save money for port customers.”

Deeper water. The infrastructure upgrade with the greatest impact, however, is the Savannah Harbor Expansion Project, which recently garnered full federal approval. The project will increase harbor depth from 42 feet to 47 feet.

Post-Panamax vessels more efficiently served by a deeper harbor in Savannah will lower shipping costs for containerized trade by $213 million per year over the next 50 years, for a total economic benefit of $10.7 billion during that span, according to U.S. Army Corps of Engineers studies. Reduced costs per container will lower the bottom line for the more than 21,000 U.S. businesses, and thousands of international organizations, shipping via the Port of Savannah.

The Port of Savannah has already positioned itself as the busiest gateway for commerce to the Southeast, notes GPA Board Chairman Robert Jepson.

“Georgia’s ports have become leaders because their superb landside infrastructure, geographic proximity to high demographic density, and overall service efficiency enables cargo to move to inland destinations more quickly and cost effectively than other ports through our direct road and rail connections,” Jepson says. “The last remaining piece of the logistical puzzle that must be improved is deeper water. With a deeper harbor, the Port of Savannah will improve its service times for the larger and more heavily laden vessels that are the future of global trade.”

INFRASTRUCTURE RULES

Every year, it seems, Georgia takes another giant leap in its quest for logistics leadership. But the starting blocks remain its infrastructure and location.

“Georgia has been rated the best state for doing business, and a lot of that has to do with its supply chain and logistics infrastructure,” says Page Siplon, executive director of the Georgia Center of Innovation for Logistics, the state’s leading resource for fueling logistics sector growth and global competitiveness.

Siplon and his team are charged with helping Georgia maintain and enhance its dominance in the logistics marketplace. The Georgia Department of Economic Development operates six Centers of Innovation focused on strategic industries: aerospace, agribusiness, energy, life sciences and IT, logistics, and manufacturing. In addition to running the logistics center, Siplon also serves as program director for the entire team.

Under Siplon’s leadership, the Center of Innovation for Logistics created and now hosts the annual Georgia Logistics Summit, the only industry-driven, state-led event of its kind and size in the nation. The Center also produces multiple publications, including a detailed industry report and a monthly Logistics Market Snapshot that serves as a valuable resource for professionals around the world.

The Center directly helps companies overcome challenges and capitalize on opportunities related to freight movement. “We provide focused technical expertise, industry-specific data, connections to state resources, and an extensive cross-sector industry network,” Siplon explains.

Siplon and his team are mindful that Georgia’s inherent location and infrastructure advantages are not enough to ensure the state remains the leader of the pack in the digital age.

“Consumers are changing the way they buy products, and the timeline in which they demand delivery,” Siplon says. “The Centers of Innovation focus on how industries are evolving, and how businesses must adapt.

“E-commerce is flourishing in Georgia,” he adds, citing a Home Depot fulfillment center in the Atlanta suburb of Locust Grove, and an Academy Sports + Outdoors fulfillment center in Macon. “We’re having exciting discussions about leveraging Georgia as an e-commerce fulfillment springboard.”

That phenomenon requires companies to constantly question their strategies. “Businesses analyze how they can keep up with shifting paradigms,” Siplon says. “Many markets are changing, and the Centers of Innovation help companies find ways to adapt so they can connect, compete, and grow.”

PARTNERS IN PROGRESS

Driving Georgia’s progress in the logistics sector are companies that are themselves leaders in the field. Many of these businesses were present at the 2014 Georgia Foreign Trade Conference to ensure they did not miss a single milestone in Georgia’s race to the top.

“Great things are going on in Georgia,” says Bill Stankiewicz, senior vice president of HWC Logistics “The state continues to be a catalyst for our company’s growth.”

Founded by CEO Mike Owens as a courier company operating one vehicle in 1981, Forest Park, Ga.-based HWC is now a single-source provider of distribution, warehousing, transportation, and import and export services.

“HWC helps shippers eliminate confusion, because our services are tied together,” Stankiewicz says. “Shippers get the experience and dedication of a single team with an integrated service platform that is committed to helping them grow their business.”

Georgia’s logistics advantages support that mission, says Stankiewicz, citing the state’s expanding air cargo business, outstanding highway system, deepwater developments, intermodal shipments, and rail superiority.

“All those elements add up to an excellent location,” he says. “The infrastructure exists for real growth.”

The companies that will share in that prosperity are those willing to invest in order to take full advantage of it, Stankiewicz says—and HWC is doing just that. “We have invested more than $2 million in assets and equipment to prepare for expansion,” he notes.

HWC’s leaders are excited about the prospects of capitalizing on an improving economy, coupled with the strategic position of the company’s warehouse facilities in Atlanta, Savannah, and Charlotte.

HWC’s transportation division—which provides full truckload, regional, local cartage, container drayage, and expedited services—recently acquired 20 new Freightliner and Mack sleepers and day cabs.

The company also upgraded its technology platforms with the addition of a new transportation management system that enables mobile data connections with drivers, allowing HWC to provide shippers with supply chain visibility.

HWC’S WAREHOUSE FOOTPRINT

In total, HWC Logistics maintains a 900,000-square-foot footprint driven by an integrated warehouse management system. The company’s Savannah facility—which sits seven miles from the port, and offers 227,500 square feet of space—continues to benefit from the port’s dynamic growth. HWC Savannah provides distribution, transload, crossdock, and import /export services, as well as heavy lift, oversize, and out-of-gauge cargo capabilities.

HWC also invests in its workforce to ensure superior service. “Training never stops at HWC,” says Stankiewicz. “People are our greatest assets, and we support worker education.”

The company’s core values support its dedication to not only keep pace with Georgia’s leadership role in logistics, but also help set that pace. The values focus on facilitating problem-solving, being easy to do business with, striving for excellence, and retaining customers by fulfilling all their supply chain needs.

PAYING IT FORWARD

Partners in progress can be found all along the supply chain. Another Georgia innovator is freight process outsourcing specialist DDC FPO.

Freight process outsourcing, or FPO, refers to digitizing, capturing, and processing bills of lading, invoices, and other documents critical to motor carriers. With a hybrid model of onshore project management and offshore production, DDC FPO chose Atlanta as home for its U.S. headquarters and project management team. The company currently processes 20 percent of all less-than-truckload (LTL) bills in America.

DDC FPO is a division of The DDC Group, which has been designing and implementing business process outsourcing solutions since 1989. With operations across North America, Europe, and Asia-Pacific, DDC’s 3,500-person staff delivers services in more than 20 languages.

In February 2014, the American Trucking Associations (ATA) named DDC FPO to its list of Featured Business Solutions for a second consecutive year. In 2013, ATA recognized DDC’s remote freight bill entry; most recently, the spotlight is on its intelligent data capture technology, iCapture.

DDC FPO lists Georgia’s central location in the Southeast, the proximity it offers to its clients, and Atlanta’s role as a hub for many of today’s Fortune 500 companies as primary reasons that logistics plays a critical role in the region.

“A diverse and strong allied community supports the trucking industry,” says ATA President and CEO Bill Graves. “Companies such as DDC FPO help ATA’s carrier members move America’s freight more efficiently and safely than ever before.”

Georgia’s booming business environment provides DDC FPO with a wealth of potential clients. “The state’s extensive logistics infrastructure attracts major freight players to establish significant operations in the state,” says Chad Crotty, DDC FPO’s vice president of sales.

The company’s Georgia location also helps it stay connected to customers. “We leverage the proximity of our project management center to the Atlanta airport to offer nearshore, face-to-face support for all our clients,” Crotty says. “Even those who aren’t headquartered in Georgia have major hubs here, and are able to reach us easily when they want to see their dedicated project managers.”

Crotty cites the Georgia Center of Innovation for Logistics as a key industry resource. “We lean on the Center for up-to-date research on the freight industry so we can anticipate the challenges our customers may face, and serve them better in the future,” he says.

The company also finds Georgia’s talent pool an important asset. “The DDC project management team requires a specific, high-level skill set,” says Tammie Schell, DDC’s director of U.S. operations. “In addition to a background in supply chain, logistics, or freight business processes—which many Georgia universities are now offering degrees in—we also need team members who will offer our clients organizational structure, clear and consistent communication, and time management. Our project managers are the links between several parties, including the client, IT staff, offshore production, and executive teams.

“Our project management team also must have quick and effective problem-solving skills,” Schell adds. “Unexpected challenges arise on every project, and can be detrimental if not mitigated correctly. Georgia’s talent pool has what we, and our clients, are looking for in a strategic, strong, and intelligent nearshore support system.”

JUST THE FACTS

For Duane Newman, director of operational excellence at Augusta-based 3PL RBW Logistics, business success in Georgia is a simple matter of fact.

“You cannot deny the statistics,” he says. “There is no question our advantages directly relate to our location and infrastructure. Georgia has thousands of miles of federal and state highways, thousands of miles of railroad track, six world-class intermodal facilities, and the largest intermodal facility on the East Coast.

“The Garden City Terminal in Savannah is the fourth-largest and fastest-growing container port in the nation, and the Port of Brunswick is the third-busiest port for auto imports,” Newman adds. “Additionally, Georgia ranks fifth in the nation for logistics and supply chain employment.”

The stats add up to the perfect environment for logistics innovation. RBW Logistics, a fourth-generation, family-owned business, is celebrating its 60th anniversary in 2014. The company provides supply chain solutions including warehousing and distribution, transportation, brokerage, packaging, sub-assembly manufacturing, and contract labor management.

“We support our customers in developing a smarter supply chain,” Newman says. “Helping them effectively manage their cash flow while increasing speed to market is key. We use our assets to continuously improve product flows and increase responsiveness to customer demand. The game is constantly changing, so we have to be flexible and adapt quickly by effectively balancing component sourcing, packaging, production, transportation, and inventory.

“We are not just a warehouse, trucking company, or transloader,” headds. “Those definitions come with too many limitations, and lack the creativity required to effectively manage today’s supply chain.

“What we do is something more. We are problem-solvers—forward thinkers with leading logistics strategies designed to increase flexibility, lower costs, and improve customer satisfaction,” Newman says. “Whether our clients are looking for basic logistics functions, vendor managed inventory strategies, or integrated just-in-time materials delivery to the manufacturing line, we find creative solutions to improve the way they do business.”

RBW works closely with state government agencies to enhance Georgia’s logistics advantages. “We are honored and privileged to have strong support from our state government agencies, including the Center of Innovation for Logistics, the Georgia Ports Authority, the Georgia Chamber, and the economic development and transportation departments,” Newman says.

Based in the Atlanta suburb of Johns Creek, Saia Inc.. is another transportation and logistics provider taking advantage of Georgia’s assets. The company’s network of 147 terminals covers 34 states.

Through its network of partners, Saia serves the balance of the United States, including Alaska and Hawaii, plus Canada, Puerto Rico, and Mexico. With revenues of $1.1 billion, Saia employs 8,400 people nationwide through three operating service groups—Saia LTL Freight, Saia Truckload Plus, and Saia Logistics Services.

Sally Buchholz, the company’s vice president of marketing and customer service, cites a plentiful, professional workforce; typically fair weather; and easy access points to highways as Georgia’s greatest advantages. Additionally, Atlanta’s world-class airport offers direct service to all major metro areas, making travel easy.

“Our workforce consists of hard-working, highly qualified employees,” Buchholz says, adding that the state’s quality of life and relatively low cost of living make it easy to attract out-of-state candidates.

“It benefits us to be able to hire from a pool of talented candidates living and working in the area, as well as attract folks who are willing to relocate here,” she says.

In addition to its headquarters in Johns Creek, one of Saia’s largest facilities is located in Ellenwood, Ga., 20 minutes from Atlanta. The company also operates four other terminals in the state. “Because of Georgia’s highway system, we are able to efficiently move freight into and out of the state,” Buchholz notes.

“Saia is proud to call Georgia home,” she adds. “And we employ 1,000 workers around the state, which provides Georgia a tremendous economic boost.”

HERE TO THERE

Logistics operations are all about getting products from Point A to Point B, according to logistics provider a2b Fulfillment, based in Greensboro, Ga., located on Interstate 20, about 80 miles east of Atlanta.

“Our location means we have access to the metro area’s infrastructure, but our costs are lower because we’re in a small town,” says Ayal Latz, a2b’s president and founder.

In the true Georgia spirit of solving problems rather than complaining about them, Latz created a2b to fill a need.

“My small, family-owned toy company needed quality, affordable fulfillment services,” he explains. “After several unsatisfactory attempts at outsourcing, I decided that we—as well as other companies out there—deserved better, and set out to create a cost-effective, service-oriented third-party logistics solution that would help small and medium-sized businesses compete and succeed.”

Established in 2001, a2b began by serving just a few toy manufacturers from a 2,000-square-foot room. “Today we serve more than 100 companies of all sizes, across many industries and product categories,” Latz says. “Our 450,000 square feet of space is outfitted with the latest distribution technology and handling equipment, and our people are the best and most talented logistics professionals.”

One of a2b Fulfillment’s best decisions was locating the company’s headquarters in Georgia, Latz says.

“Georgia enjoys a logistical advantage because of its mature infrastructure, including road, air, sea, and rail; business-friendly tax climate with initiatives such as free trade zones; and geographical proximity to the majority of the United States,” he says. “We chose Georgia as headquarters for all those reasons. Leveraging these benefits allows our clients to provide their customers with a great experience by delivering orders quickly, while simultaneously improving bottom lines by sourcing the least-expensive shipping method.”

The company offers numerous back-end support solutions, as well as value-added services such as kitting and assembly, returns management, and product refurbishment.

Although it is a small town with 3,000 residents, Greensboro is close to some of the biggest logistics assets anywhere in the world, which works in a2b’s favor.

“In addition to our proximity to Atlanta, we’re also located just three hours from the Port of Savannah,” Latz notes. “We receive containers quickly at a reasonable dray cost, then the goods are positioned closer to the next leg in the supply chain, whether that’s for local or national delivery.

“Because our costs are low, we can offer storage, handling, and value-added services at lower rates than our competitors in Atlanta and even Savannah,” he adds.

As a third-party fulfillment services provider, a2b handles large volumes of parcel and LTL shipments. “Most of our clients use a2b as their sole fulfillment facility because it eliminates the complexity of staging inventory in multiple locations,” Latz says. “It is often not worth the headache for them when we can reach the majority of the population quickly and cost-effectively.

“Additionally, our proximity to the world’s busiest airport allows us to support clients with expedited import/export needs,” he adds.

a2b works closely with the Department of Economic Development, the Greensboro Chamber of Commerce, and the Center of Innovation for Logistics to help promote Georgia and offer support to companies considering moving there. “All these agencies are forward thinking and solicit our feedback,” Latz says.

WHERE THE HEART IS

Bruce Heuer, CEO and president of forklift fleet management company CJK Services Inc.., has called several places home during his years in the forklift business. Today, he is happy that CJK’s home is the Peach State.

“Georgia is a favorable place to build a business,” the New Jersey native says, citing the state’s favorable taxes, low cost of living, and mild climate. “Our business model is not dependent on geographical location, but it would take a bazooka to get us out of here.”

Started in 1992, CJK Services is located in the Metro Atlanta city of Lawrenceville. The unique business Heuer launched from his Georgia basement became fully incorporated in 1999, and now functions as a “cradle-to-grave” forklift fleet management company offering forklift repair analysis, forklift information management, and customized reporting services.

“We are a client advocate,” Heuer explains. “Companies are in the forklift business by default, not by design. We provide the expertise to measure their forklift fleet’s effectiveness and efficiency. And because we are an advocate, we are supplier- and manufacturer-agnostic. We provide the information the client requires to maximize that asset at the lowest possible cost.”

CJK’s team evaluates repair bills, monitors equipment performance, and suggests ways to improve the fleet. “Our team has decades of experience in generating maximum uptime and financial efficiency from forklifts in every type of industry,” Heuer says.

“We employ an effective combination of experienced analysts, professional and dedicated client team specialists, and a state-of-the-art database that generates winning results for our clients,” he adds. “By scrutinizing repairs and component failure rates, the CJK Services team ensures our clients receive the best value for each maintenance dollar they spend.”

CJK specialists convert raw data into usable information clients need to maximize their forklift fleets at the lowest possible cost. And that is a good deal anywhere on the map.

HITTING THE SPOT

Having the right spot helps, however. “Logistics is about location, location, location,” says Ben Goldberg, president of JIT Warehousing & Logistics. “Savannah is the Southeast hub of the population explosion.”

JIT Warehousing & Logistics operates throughout the United States, handling numerous commodities, steel products, and palletized cargo. Located about one half-mile from the Port of Savannah’s Ocean Terminal, JIT offers crane service and direct discharge from the port. With more than two decades of experience in the import/export industry, JIT provides warehousing, trucking, shipside delivery, port pickup, container draying, stripping, stuffing, and crossdocking.

In 2013, JIT opened a facility on the CSX rail line. The new facility joins the company’s 75,000-square-foot warehouse, opened in September 2010 on the Norfolk Southern line. JIT also operates three previously established locations in Savannah.

While Goldberg joins in the excitement of post-Panamax vessels making their way to the Port of Savannah, he believes Georgia’s record of attracting new businesses and residents is just as important.

“Big ships coming in is not the only new development on the horizon,” he says. “The area’s population growth is also significant.”

So is the increase in cargo coming in—and, for that matter, going out. The Port of Savannah’s logistics advantages work for both imports and exports.

IT’S ALL ABOUT TEAMWORK

Goldberg credits much of Georgia’s logistics growth—and his business’ success—to the agency governing the ports. “The Georgia Ports Authority is in touch with us daily about potential business,” he says. “We work as a team. If it weren’t for the GPA’s support, we wouldn’t be here.”

Goldberg’s daughter, Evelyn Goldberg-Davis, serves as JIT’s vice president, and tracks the company’s recent success. “JIT has grown 10 to 20 percent over the past three years, with 30-percent growth in 2013,” she notes.

Proximity to the Port of Savannah also represents a major advantage for Atlanta-based Nordic Logistics and Warehousing, the second-largest cold storage operator in the Southeast, and the eighth-largest in North America. Nordic specializes in providing cold storage and distribution services to major food producers, distributors, retailers, and other blue-chip customers. The company operates 13 facilities in Georgia, Alabama, Mississippi, and North Carolina, which together comprise more than 80 million cubic feet of temperature-controlled storage.

Nordic’s Savannah facility opened in April 2013 in response to customer demand for lower logistics costs for Africa, Asia, the Middle East, and Russia exports. With more than 10 million cubic feet of convertible temperature-controlled storage space, the facility is located just six miles from the Savannah port, and provides shippers convenient access to the port, dual rail/intermodal services, and major interstate highways.

In late 2013, Nordic received approval to ship to Russia and the European Union from the company’s new Savannah facility. “Now our customers have the option to ship heavyweight containers to Russian and EU markets,” says Bill Crotty, senior vice president, sales and logistics.

“Nordic can load maximum product weight in containers for export, and receive maximum weights on imports,” says Don Schoenl, president and CEO of Nordic. “Our associates, transportation services, and technology offer shippers the most expeditious means of getting products to consumers.”

The Savannah facility offers blast freezing for all protein commodities, refrigerated product storage, drayage in and out of port, and product identification and recall services.

Nordic works closely with several Georgia government agencies—particularly the Georgia Ports Authority, Department of Economic Development, Georgia Centers for Innovation, and the Savannah Economic Development Authority—to enhance the state’s logistics advantages, says Ross Maple, director of business strategy at Nordic.

In the Atlanta market, the company operates three multi-customer distribution centers: one near Hartsfield-Jackson International Airport, one in northeastern Atlanta, and one northwest of the city. Together, these facilities have provided flexible solutions for shippers by offering warehouse and transportation services for retail, foodservice, and export businesses for more than 70 years.

Another company finding Georgia an ideal home for growth is Outsource Logistics. Founded in 2000 in a small warehouse with one delivery van,Outsource Logisticshas become a leader in total supply chain solutions in the Southeast, with growing national influence.

Located in Valdosta, Ga.—halfway between Atlanta and Orlando—Outsource Logistics operates three distinct divisions and maintains more than 750,000 square feet of third-party and dedicated warehouse space, along with turnkey logistics solutions.

Outsource Logistics provides a full range of warehousing services, a trucking fleet, and total LTL and FTL brokerage solutions for a seamless distribution package for dry freight, hazardous materials, and food-grade items.

Offering an Internet-based LTL transportation management system—along with van, flatbed, refrigerated, intermodal, and freight pooling services in one seamless system—makes Outsource Logistics a “total” distribution package.

Its location in South Georgia on Interstate 75 allows Outsource Logistics to provide next-day service to Florida, Georgia, Alabama, Mississippi, Tennessee, South Carolina, and North Carolina. The company’s ability to put freight in customers’ hands in 24 hours makes this a prime distribution location.

The bustling Atlanta metropolitan area is an attractive place to locate a business—especially one providing top-tier logistics services.

“Georgia is the center of our Southeastern network,” says Jeff Rudy, president of supply chain for Unisource Worldwide, based just outside Atlanta in Norcross, Ga. “The quality of life in the area is also beneficial when we are trying to recruit and attract top-notch talent to our organization.”

Unisource helps enterprise-level companies improve bottom-line performance by providing sustainable and efficient solutions across the lifecycle of core business operations, including product packaging and fulfillment, paper and print management, general supply chain and logistics, and facility solutions.

With offices and operations in key locations around the world, Unisource is currently ranked as one of the largest privately held companies in the United States. Maintaining a global workforce of more than 4,300, and millions of square feet of supply chain capacity in 90 warehouses across North America, Unisource is a partner to many of today’s leading global organizations.

“Our two offices in Norcross serve as the center of the supply chain function for the entire organization,” Rudy says. “In addition, one of Unisource’s largest warehouses in the country is located here.”

Unisource was founded in 1968 when industrial products manufacturer Alco Standard Corporation formed a distribution company that became known as Unisource Worldwide Inc. By 1986, the company was the country’s leading distributor of paper and office products.

Unisource eventually split from Alco. It then experienced rapid growth, fueled by the acquisition of several top-rated local and regional distribution companies in North America. Georgia-Pacific Corporation, now owned by Koch Industries, later acquired Unisource. Bain Capital then gained a 60-percent ownership in Unisource, and Georgia-Pacific retained 40-percent ownership.

Today, Unisource offers a comprehensive suite of customer solutions. Capabilities include engineered packaging design, e-business technologies, logistical expertise, paper procurement services, and optimized facilities management.

“We are one of North America’s largest independent distributors and marketers of more than 150,000 national and private-label products—including commercial printing and business imaging papers, facility solutions and equipment, and packaging materials and equipment,” Rudy says.

The key to Unisource’s continued growth lies in expanding its offerings. “We consistently challenge ourselves to move up the value chain by adding more services,” Rudy explains. “Today, logistics involves a lot more than simply moving pallets of product to customers. We partner with shippers to provide solutions that help them run more efficiently. And we work with them to apply our logistics expertise to formulate a world-class plan—then take ownership of the end-to-end execution.”

Rudy echoes his colleagues’ enthusiasm for the quality of Georgia’s workforce. “The primary advantage Georgia offers is the large number of well-qualified supply chain professionals who are attracted to the Atlanta area,” he says. “The region’s universities have excellent supply chain programs. We routinely hire graduatesfrom the University of Tennessee, Georgia Southern, Auburn, and Georgia Tech, and we are always impressed with the work skills these young people bring to the company. They have a sense of enthusiasm that enhances the organization’s energy, making this a great place to work.”

WHERE TO WAREHOUSE

Companies seeking warehouse space in Georgia have no shortage of options. TakeAtlanta Bonded Warehouse (ABW), for example.

“We serve businesses that need regional warehousing, as well as transportation and co-packaging/repackaging services,” says Hal Justice, vice president of sales and operations for ABW. “We’re able to provide those services because of the distinct advantages that Georgia offers.”

ABW’s perspective on Georgia reflects its long and storied history in the state. The company was organized in 1948 by a Peter Paul candy broker seeking to provide protective warehousing to the confectionery industry. The company operated under the name Acme Bonded Warehouse until 1981, when it adopted its current name.

Today, ABW offers more than two million square feet of modern, secure, high-cube storage capacity. Its main metro Atlanta campus is in Kennesaw, convenient to major interstate highways and served by CSX rail service.

“Georgia has several distinct logistical advantages,” says Joe Keith, ABW president. “It is home to the United States’ easternmost major port on the Atlantic, an extensive interstate highway system, a well-developed intermodal network, and the growing airfreight hub at Hartsfield-Jackson International Airport.

“These four attributes—plus access to other Mid-Atlantic and Gulf ports—make north Georgia a unique crossroads to serve the Southeast and beyond,” he continues. “It also is an advantage to have a pool of skilled labor to staff our growing needs.”

“The primary advantage Georgia offers is the large number of well-qualified supply chain professionals who are attracted to the Atlanta area. “—Jeff Rudy, Unisource Worldwide

Atlanta Bonded Warehouse strives to make the most of each of these assets. “What distinguishes ABW is the longevity and experience of our management and workforce, the relationships we have built with customers, and our performance,” says Fred Keith, the company’s CEO. “We also work with state and county agencies to promote and deliver Georgia’s logistical advantages to new and existing customers.”

Another Atlanta warehousing option is Americold, which owns and operates 177 temperature-controlled warehouses in the United States, Australia, New Zealand, China, Argentina, and Canada. Established in 1931, the company also offers transportation and logistics, and focuses on serving the food industry.

Americold’s cold storage network offers a total capacity of more than 1.1 billion cubic feet of storage. The company’s warehouses play an integral part in Georgia’s supply chain, connecting food producers, processors, distributors, and retailers to end consumers.

Georgia’s vast reach in the logistics universe extends even beyond air, land, and sea. Atlanta-based Supply Chain Logistics Software Innovators (SCLSI) is bringing a new dimension to the logistics marketplace through cloud-based technology.

The company, launched in late 2013, is built on the shared vision of co-founders Daniel Grabowski and Witold Chamielec to deliver cloud-based software solutions for the supply chain sector both domestically and internationally.

“We offer a single cloud-based logistics and communication solution that efficiently and effectively provides the tools needed for a successful supply chain,” says Grabowski, the company’s CEO. “SCLSI delivers affordable supply chain software solutions that complement freight forwarder, supplier, and customer systems.”

INNOVATIVE INSIGHT

With a combined 44 years of experience in logistics and software development, Grabowski and Chamielec bring innovative insights into the logistics sphere. “We created a platform with high-transparent visibility for all vendors in the supply chain,” Grabowski says. “We do not believe this has been previously refined and made efficient in the marketplace.”

The company strives to drive down transaction costs by eliminating the manual tasks pervasive throughout the supply chain. Bridging the transportation process with customer ERP solutions provides a collaboration portal where suppliers, forwarders, and shippers work together in a transparent business process, reducing costs by automating manual and disjointed efforts, and enhancing total visibility and reporting throughout the supply chain.

Through SCLSI’s software, everyone from suppliers through end customers can remain in constant contact as products flow from point to point. “We are a true cloud-based solutions company,” Grabowski says.

Grabowski’s partnership with Chamielec, who is based in Charlotte, N.C., gives the firm a Southern flavor, but its market stretches around the world. The company is currently developing clients everywhere from New York and Chicago to Asia.

“Our solution flows seamlessly from sales order to buyer planning, supplier quotation, order generating, supplier booking, and the forwarder generating a shipment plan for the customer to review, improve, and approve,” Grabowski says.

“Once approved, the system tracks the entire shipment transportation process all the way through to delivery,” he continues. “Our business process management product steers the expectations of the entire process, yielding true performance monitoring of all trading partners in the supply chain.”

While the wonders of cyberspace put the company anywhere at any time, Grabowski is pleased to be planted in Georgia, where the New York native has lived since 1999. He cites the compelling advantages of doing business in Georgia, including property rental costs, taxes, and the quality of employees.

“Quite a few large forwarders operate here,” he says. “And Atlanta is home to many technology companies. So finding people who are suited and qualified to work in our field is not an issue.”

Moreover, Grabowski says, the city is, in many ways, the hub of the universe. “Atlanta is reaching out to all parts of the world from Hartsfield-Jackson International Airport,” he notes.

THE TECHNOLOGY EDGE

Georgia’s place as a leader in the information technology field gives logistics providers in the state a special edge.

“I don’t have any trouble attracting technology professionals to my IT department,” says Brian Kinsey, president and CEO of Brown Integrated Logistics, a dedicated transportation and logistics services provider based in Lithonia, Ga., less than 20 miles east of Atlanta on I-20.

“There’s a wealth of IT talent in this area. My staff is essentially Georgia-educated,” Kinsey says. “We do a lot of our own network and systems development, and our infrastructure never goes down.”

The IT advantage is especially important as the field of logistics changes. “We have evolved into an information services company with 1,000 trucks,” Kinsey says. “Our clients want to know where their products are at all times, and they want an invoice that ties into their general ledger. We give them all that and more. We offer real-time visibility to their products.”

Brown focuses its services on the middle of the supply chain. “It has become standard practice to do an outstanding job of picking up and delivering product,” Kinsey says. “But what happens in between—and delivering accurate information about it—is equally important.”

Kinsey speaks of Georgia with the fondness of a traveler who has finally found his home. “I have lived in 11 other places,” he says, “and I never want to leave here.”

The Maryland native earned his bachelor’s degree at Georgia Tech before heading to Harvard Business School for his MBA. Kinsey’s professional travels brought him back to Georgia in 2000.

“Georgia is in the middle of it all,” he says. “It is a hub. It is one of the few states home to a highly evolved interstate transportation system, railroads, ports, and airport. And it is centrally located, so you can get to any state in the South within six hours.”

Kinsey feels an affinity with the company’s founder, who chose Georgia to grow his business. “Brown Integrated Logistics was established in Georgia,” Kinsey says, “and we see no reason to leave. We have an outstanding workforce and well-respected universities.”

The company’s story is one of growth. James W. Brown started out in the trucking business in West Virginia in the mid-1960s with one dump truck, then moved to the Atlanta area in the early 1970s. He started James Brown Trucking Co. with four trucks, and incorporated James Brown Contracting Inc. in 1976.

In 2008, after 40 years of building and running his trucking business, Brown retired. He sold the business in May 2008 to Navigation Capital Partners, an Atlanta-based private equity firm. Both the new owners and the management team are committed to carrying on Brown’s legacy of dedicated on-time service, and to growing and expanding Brown Trucking while retaining the company’s family atmosphere.

In 2010, James Brown Contracting completed two transactions that resulted in the acquisition of five companies, including warehousing, brokerage, full-service leasing and maintenance, and dedicated and regional truckload services. With these acquisitions, Brown significantly expanded its customer and commodity base, and added a number of logistics services that created greater value for customers.

In 2012, Brown Integrated Logistics was formed, with its subsidiaries Brown Logistics Services, West Logistics, Brown Fleet Services, and Brown Trucking. Together, these companies provide a suite of world-class logistics services.

Georgia provides the perfect environment for growth, says Kinsey. “It is an advantage to be located where manufacturing is growing,” he explains. “Auto assembly plants and factories are still being built in the Southeast.”

And that, he says, circles back to the company’s roots. “Growth in the South brought James Brown to Atlanta all those years ago,” he notes. “And the growth hasn’t stopped.”

A BEST-KEPT SECRET

For Peter Thomas, general manager of GE Transportation’s Optimization Solutions, the advantages of having his home base in Georgia are both personal and professional.

“Georgia is a best-kept secret,” Thomas says. “It has everything from big cities to the mountains to the coast. And the Atlanta airport gives us access to the world.”

From its headquarters in Atlanta, GE Transportation’s Optimization Solutions provides software and solutions to the railroad industry and industrial shippers. “We solve tough rail transportation challenges by leveraging in-depth knowledge of rail operations, intermodal terminal operating systems, and multi-modal transportation management,” Thomas explains.

The company’s software manages rail and intermodal operations, signal and communication assets, railcar repair billing and maintenance, and multi-modal visibility, planning, and execution.

Thomas became general manager of Optimization Solutions in 2012 when GE Transportation, maker of rail and transportation-related products, acquired Railcar Management (RMI), a company founded in 1979 to serve the rail industry’s need for accounting and railcar management. In addition to Atlanta, the $5.5-billion company operates sites in Melbourne and Jacksonville, Fla.

Optimization Solutions is developing an “Industrial Internet” for railroads and rail shippers that helps machines communicate with information networks and people to improve asset, operations, and network performance. These technologies will enable the company’s railroad and rail shipper customers to minimize complexity and eliminate waste.

“Shippers in North America spent more than $40 billion in 2012 on overhead, administration, and warehousing,” Thomas says. “Improving efficiency by just one percent results in $400 million in annual savings. Automating and connecting the shipper to the rail network further automates the railroad, creating a ‘network effect’ of additional productivity.”

The blend of Georgia’s transportation heritage and GE’s focus on cutting-edge technology gives the company the best of both worlds. “Our Georgia location is a huge advantage for our customers and for us,” he says. “We are a technology company, but in Atlanta our optimization solutions business is primarily a software company. We use software technology to help customers connect, and integrate the rail transportation landscape.”

KEEPING TRACK

Yet another logistics sector innovator that calls Georgia home is Global Resource Group (GRG) GPS Fleet Solutions. The company—founded in 2001 and headquartered in the historic town of Stockbridge in the Atlanta metropolitan region—specializes in GPS asset tracking, risk management, driver safety, and compliance.

“GRG has worked with thousands of companies across the United States and Canadato help them control fleet expenses and DOT compliance, and improve profitability through productivity and risk mitigation,” says Greg Nacke, the company’s director of business development.

“We have experience with fleets ranging from a single vehicle to more than 9,000 vehicles,” he adds. “We work with municipalities, service and delivery fleets, and many others. GRG Fleet Solutions’ extensive experience allows us to consult with prospective customers to match the right system to their requirements—and sometimes discover a few needs they were not aware existed.”

GRG seeks to identify enterprise customers’ needs through an extensive and defined discovery process that looks at all aspects of a business—from fleet operations to risk management, dispatching, and administration.

GRG’s solutions include various telematic products that help customers understand the risk their fleets represent, and possible actions to mitigate that risk. The process uses engine diagnostics in real time to provide detailed information on speed, miles driven, harsh braking, jackrabbit starts, and vehicle systems performance. The information these systems create can be integrated directly into all business applications through an automatic real-time or batch process, maximizing the ROI of telematics data.

“With proper data management, fleet operators can cut expenses through risk and safety improvements never before possible, and gain the routine benefits of improved efficiency, accountability, productivity, customer service, and dispatching,” Nacke says.

GRG Fleet Solutions contributes to Georgia’s leadership in logistics innovation with a full-time business analyst who helps clients evaluate technology and quantify value based on their operational environment. “We use that data to recommend fleet operations improvements,” Nacke says.

“The two biggest sources of expense—drivers and fleets—are unsupervised 95 percent of the day,” he explains. “Our business analyst helps companies understand the true cost of fleet operations, and cut associated expenses while improving revenue.”

GRG helps companies determine what type of solution they need. “Knowing where to invest your money is important,” Nacke says. “Often companies speak to numerous GPS vendors, combine all the features and functions into a massive document, then spend years searching for one system that does it all. During the years spent looking for a system that does not exist, they miss their ROI 10 times over. Our process is founded on a proven approach to discovering customer needs.”

GRG Fleet Solutions offers a variety of training opportunities ranging from online videos to custom one-on-one training programs at the customer’s location. Online training includes screen casts, tech tips, manuals, diagrams, podcasts, and full-length videos on subjects such as installation. “Our training program is a living, growing part of our service, and we are very proud of it,” Nacke says.

CHANGING TIMES

As the leader of a company that now involves three generations of his family, Jim Syfan, CEO of 3PL Syfan Logistics, has seen—and led—change in the logistics sector in Georgia for nearly five decades.

“In the beginning, we managed operations using a notepad and a rotary phone,” he recalls. “The first computer I used was an IBM that was bigger than a refrigerator. It could subtract, but it did not divide. Those were commercial transportation’s infancy days.”

While Syfan Logistics was not established until 2011, its birth can be traced to 1984, when Jim Syfan founded Turbo Logistics. Now he and his two sons, Greg and Steve, run the company from its Gainesville, Ga., headquarters, 55 miles north of Atlanta on I-85.

“Our customers and carriers did not have computers when we started,” says Greg Syfan. “Now we have technology on all our trucks, with GPS devices downloading right into our system.”

The company uses a system from technology provider MacroPoint to deliver location tracking and mobile-asset management capabilities.

“On the horizon is determining how social media can impact connections,” Jim Syfan says. As drivers wait for products to be loaded, they communicate on social media sites such as LinkedIn. “Connecting with business contacts online helps us better serve them,” he says.

If the senior Syfan seems as enthusiastic about changes and growth in the logistics sector as he did when he started the company, it is because he remains at the forefront of that evolution. Recently, the governor’s office invited him to participate in a project at the Georgia Center of Innovation for Logistics to develop software that facilitates connections between logistics companies and manufacturers.

Syfan cites the cooperation and leadership of other industry groups as reasons Georgia finds new ways to stay a logistics leader. “Our local Chambers of Commerce are active in inviting manufacturers and distributors to the state,” he says.

The Syfans feel a personal responsibility to their company’s customers—a bond represented by the business sharing the family name.

“Customers will never call Syfan at 2 a.m.—whether on Thursday or Sunday—and get an answering machine,” Greg Syfan says. “Anybody can be available during normal hours. We are accessible at all times, and we always tell the truth.”

ROOTED IN GEORGIA

It’s an attitude rooted in the Georgia ideals that Jim Syfan grew up with.

“One of Dad’s philosophies that he instilled in us is, ‘Don’t ever tell a customer no,” Steve Syfan says. “That doesn’t mean we will lie; it means we will offer options to help.”

Jim Syfan considers the company’s service approach an age-old principle that will never change. “Treat people like you want to be treated,” he says.

ON THE GROW

For all the logistics advantages Georgia offers today, industry insiders say opportunities are only going to expand.

“We are looking forward to growing our footprint in Georgia,” says Alex Stark, director of marketing for third-party logistics provider Kane Is Able (KANE). “We’re excited about expanding our logistics capabilities in Georgia. It’s the right place for us to be.”

The 3PL helps consumer goods companies effectively and efficiently distribute products throughout the country. Its value-added logistics services for this sector include integrated distribution, packaging, and transportation solutions specially designed to meet the needs of manufacturers and their retail partners. The company’s customer list includes some of the world’s most respected consumer product companies and retailers.

In September 2013, the Scranton, Pa.-based firm expanded its distribution and transportation operations in the southeastern United States with a new Georgia distribution center. KANE relocated from its former location in Lithia Springs, Ga., to a new 426,000-square-foot DC eight miles away in Atlanta.

The family-owned company’s Atlanta facility is an integral part of KANE’s extensive logistics network, and the newest tangible symbol of the company’s growth. In 1930, Edward Kane traded his car for a used truck to provide local hauling to valley regions of Northeast Pennsylvania. Today, KANE manages a truckload fleet of 140 power units and 800 trailers, and operates more than seven million square feet of 3PL warehousing space across 21 U.S. distribution center locations.

The new building in Atlanta allows KANE to enhance services to its current client base, and to offer warehousing, distribution, transportation, deconsolidation, consolidation, and packaging services to other companies that need an economical distribution solution for the Southeast region.

The food-grade facility offers convenient access to Interstates I-20, I-285, I-85, and I-75. “It also puts us right on the CSX rail line,” Stark says. The building includes a professional office suite that now serves as KANE’s regional office for the Southeast.

“KANE offers a variable‐cost distribution solution with our premium, multi‐client distribution center in Atlanta,” explains Stark. “As throughput changes during the year, companies pay only for the warehouse space and labor they need. The result is a powerful, adaptive distribution capability with no capital investment.”

Georgia’s strong employee base makes it an ideal location for KANE. “You’ve got to go where the talent pool is,” Stark says.

STAYING AHEAD

“If I were looking at it just as a strategic analyst, I like Georgia’s prospects,” says T. Michael Riggs, chairman and majority owner of Jack Cooper Transport, a finished vehicle logistics and auto-hauling trucking company headquartered in Atlanta.

“Georgia is a mecca for talent, partnerships, and players,” he adds. “It’s the right time, place, and attitude for growth, and Georgia has a cost-effective, easy-to-navigate infrastructure.”

Jack Cooper’s logistics division provides both land and sea vehicle transportation. The company handles cars, trucks, and equipment on wheels across the entire continental United States, and exports on a regular basis to Africa, the Middle East, the Caribbean, South America, Europe, and Asia.

The international reach from Atlanta far exceeds other regions’ access, says Riggs. “For example, we have conducted business meetings with the ambassador to Nigeria in downtown Atlanta,” he notes.

THE SHORT-SEA TREND

That global access is particularly helpful as the world shrinks. “There’s a new movement I call short-sea shipments,” Riggs says. “Products are shipped by water as an alternative to rail and trucks. I think the short-sea trend has about the same growth rate as intermodal.”

Which is not to say that road and rail transportation are diminishing—far from it. “We maintain a very healthy trucking carrier base in Georgia,” says Riggs. “Trucking carriers are actively supporting our ports.”

Riggs attributes Georgia’s logistics prominence to its tradition of supporting business. “It’s much easier to work in areas where the state appreciates job growth and the business community,” he notes.

Jack Cooper has contributed to that community over the years. “We will reach $1 billion in revenue this year with 5,000 employees,” Riggs notes. “I bought the business in 2008, when it was a $30-million company with 125 employees.

“We now transport light vehicles in both the United States and Canada for most major domestic and foreign automotive manufacturers, with 59 terminals, located primarily in the midwestern and eastern regions of the United States and Canada,” he adds. “We are one of the largest inspectors and shippers of pre-owned vehicles, with 20 inspection sites across the United States.

“We also have a decade-long track record of operating in Mexico, managing plants, yards, and rail operations,” Riggs continues.

The company also provides automotive transportation and logistics services to original equipment manufacturers, remarketers, fleets, auctions, and dealers.

“We deliver a full spectrum of services within the finished vehicle and remarketed vehicle markets,” Riggs says. “Unlike most industry providers, Jack Cooper Logistics offers a broad continuum of services—land and ocean transportation, rail and yard management, vehicle inspections, claims management, and title services.”

The company has made many of the right moves under Riggs’ leadership, but the Missouri native says the best move he ever made was to Georgia. “If I had to do it all over again,” he says, “I would do it in Georgia.”

It is a sentiment shared by many logistics companies, transportation providers, manufacturers, and distributors who continue to have Georgia on their minds.

For information on featuring your region in an Economic Development Supplement, contact James O. Armstrong at 314-984-9007.