9 Best Practices for Global Logistics Management

In a climate of uncertainty and disruption, companies that prioritize visibility, sophisticated tech, empowered teams, and trusted collaboration are building more resilient, responsive global supply chains.

Uncertainty continues to dominate global supply chain conversations among companies in the United States and around the world. Solutions-oriented organizations aren’t just throwing up their hands and complaining about it, though—instead, they are focusing on best practices to help navigate the challenges accompanying uncertainty, and even to seek an edge where they can.

Uncertainty isn’t merely a buzzword. “It’s the defining challenge for supply chains today,” says Richie Daigle, supply chain evangelist with Tive, a Boston-based provider of real-time supply chain visibility solutions.

“Supply chains are more volatile than ever, and disruption is no longer an occasional event, but a constant reality,” Daigle says. “Businesses are navigating cost fluctuations, geopolitical instability, labor shortages, and mounting security risks—all while customers demand faster deliveries and complete transparency.”

In the face of those demands, global trade requires more sophistication and expertise and a smarter use of resources than ever before. Companies are turning to these nine critical best practices to thrive in today’s unique global trade environment.

1. Have a Plan

Companies with global supply chains that navigated the pandemic should be able to take advantage of that experience to tackle new disruptions and periods of uncertainty when they emerge, says Don Maier, an associate professor of practice in supply chain management at the University of Tennessee.

While supply chains prioritize stability, ongoing geopolitical disruptions—whether domestic or international—are an unavoidable reality.

“Smart companies learned during the pandemic to make sure they continue to use a similar type of planning structure for any kind of potential future event,” Maier says. “All these future events will be different, so you don’t know exactly what to plan for, but at least you know what partners you may want to contact and you have a direct communication link to your primary suppliers.

“Even if you don’t implement those plans, you should have them at your fingertips, so you know what to do just in case,” he adds.

2. Manage Cash Flow

Companies that excel at managing their cash flow are best positioned to continue to thrive in ever-shifting global trade scenarios of all kinds.

“If I can manage my cash flow better than my competitors I can adjust to situations that develop,” Maier explains. “I can expand my supplier base, even though I’m not buying in larger quantities. I also might be able to accept a higher transportation cost, such as using air rather than ocean, if necessary.

“It’s the same thing with warehousing: with enough cash flow, I might be willing to expand my warehouse network because I need to bring in more inventory,” he says. “That means sitting on inventory longer before I turn it into a sale.

“But if I can manage my inventory-to-sales ratio better than my competitor, that will be beneficial for me,” Maier adds.

3. Empower Your Cross-Functional Teams

High-performing, cross-functional teams that are empowered to make network-wide decisions enable shippers “to stand above the competition,” notes Glenn Koepke, vice president, industry and solution strategy at Vector, a San Francisco-based provider of digital logistics solutions.

“Whether it is nearshoring suppliers, insourcing production, or forward-deploying products to markets that aren’t as volatile, the foundational element of success versus failure is whether your supply chain runs on high-performing teams that are empowered, motivated, and aligned with the organization’s values and goals,” Koepke says.

Similarly, supply chain leaders need to sit side-by-side with their teams so that global trade logistics remain firmly in the foreground.

“Too many decisions are made in boardrooms without a real understanding of day-to-day operations,” Koepke says.

4. Collaborate Across the Supply Chain

Companies operating global supply chains in dynamic regions like Asia need to understand the complexities of cross-border compliance and local business customs. These firms can benefit from working with logistics partners with deep international experience.

In light of the complexity of a global supply chain, prioritizing the partners you choose and the quality of your collaborations is essential. “Logistics isn’t a solo sport,” Daigle says.

“Even if you single-source materials, your suppliers rely on thousands of companies to get the material they need to produce,” Koepke says.

To navigate this interdependence effectively, more companies are turning to shared visibility. “Today, 63% of companies share visibility data with partners to improve efficiency,” Daigle notes. “The most adaptable businesses don’t simply track their own shipments—they integrate real-time insights with carriers, suppliers, and customers to create a more synchronized, responsive supply chain.”

Aligning sourcing strategies with real-time logistics conditions is also crucial, says Jeffrey Shih, CEO of Dimerco, a Taiwan-based provider of global logistics solutions. This approach often means working with partners who have the sophisticated tools and expertise that are necessary today.

“One proven best practice is to partner closely with third-party logistics (3PL) providers that offer both freight capacity and local market expertise, especially in dynamic regions such as Asia,” Shih says.

Some shippers underestimate the complexity of cross-border compliance and setup, especially when entering emerging markets such as India. They also sometimes overlook the value of international 3PLs with deep local expertise.

“As supply chains decentralize across Asia, understanding local regulations, infrastructure, and customs becomes a key advantage in managing complexity and avoiding delays,” Shih says. “Local execution delivers real speed and resilience.”

5. Focus on Operational Excellence

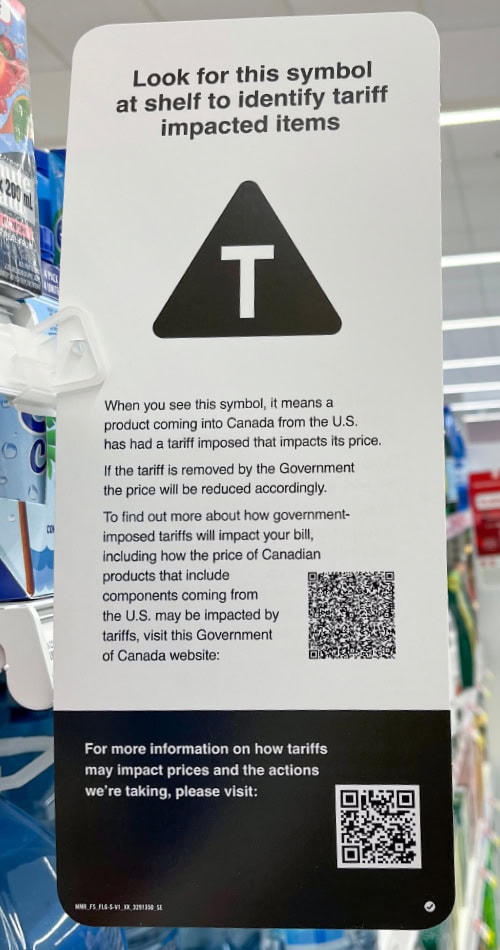

Global businesses can help offset tariff implications by using connected data systems to strengthen operations.

The current uncertainty in global trade “differs fundamentally from traditional supply chain risk management,” notes Anand Ravindran, vice president of customer operations and success for supply chain technology provider FourKites.

“Shippers are dealing with rapid, unpredictable changes in trade rules that make traditional planning obsolete overnight,” he says. With that in mind, the most effective approaches to managing global supply chains focus on operational excellence rather than dramatic sourcing overhauls.

“Companies are discovering they can offset several tariff impacts through better execution of existing operations,” Ravindran says. For instance, connected data systems are a key way to strengthen operations.

“Linking purchase orders to transportation planning to customs clearance eliminates blind spots and reduces expedited freight costs,” Ravindran says. “When systems talk to each other, you can pivot quickly rather than react after problems emerge.”

Scenario-based planning is also invaluable to shippers, including testing multiple variables simultaneously rather than planning for single-point failures. “For example, the most resilient companies prepare for their primary supplier to fail during a port strike while currency volatility spikes during peak season,” Ravindran says.

Companies may obsess over easily quantifiable risks while ignoring systemic vulnerabilities.

“They diversify suppliers geographically but use the same shipping routes, or track supplier concentration while missing port concentration,” Ravindran says. “Similarly, their investments in technology are often misaligned with where and how their supply chains are most likely to break down.

“For instance, investing in demand forecasting while managing critical supplier relationships through spreadsheets creates blind spots where flexibility matters most,” he notes.

6. Balance Infrastructure Improvements with Company Performance

Supply chain leaders tend to have an addictive mindset, thinking “more is better” and adding technology when the tech they already purchased does not do what is needed. Few companies have been able to balance infrastructure improvements with company performance, Koepke says.

“Master data is almost always shelved for new features, products, or launches, regardless of the pain it causes across nearly all supply chain systems,” he says.

“More customization and band-aids are built on top of band-aids,” Koepke notes. “This leads to poor data availability, off-line databases that only a few have access to, and forecasting models that produce great theoretical models, but the actual plan varies greatly.”

What should companies do? Strategy often ignores what’s under the hood, Koepke notes. “Supply chain leaders and executive teams need to thoroughly assess their current systems, processes, and talent, and adopt a balanced scaling approach,” he adds.

Shippers cannot control external volatility, but they can control their adaptive capacity.

“The most successful organizations have moved beyond traditional risk management to ‘uncertainty as a competitive advantage’—using their ability to navigate ambiguity as a differentiator in markets where their competitors are paralyzed by unpredictability,” Ravindran says.

7. Concentrate on Tech-Based Decision-Making

Many global companies today are still trying to contend with 2025 volatility using aged tools, outdated KPIs, and a mindset about global risk built in the 1990s. “Today, uncertainty doesn’t just punish the unprepared—it rewards the flexible, transparent, and anticipatory,” says John Carrico, vice president of product management at Epicor, a business software company based in Austin, Texas.

Artificial intelligence is among the most prominent ways for shippers to get ahead in global trade.

“AI can scan unstructured and non-obvious data—such as supplier financial filings, social media trends, port congestion reports, weather anomalies, and geopolitical news—and spot patterns that hint at emerging risks,” Carrico says.

AI presents decisions “already framed and weighted,” Carrico adds, rather than waiting for supply chain managers to notice a problem and then decide what to do.

“Humans can’t sift through 10,000 signals a day, but AI can. And it doesn’t sleep,” he says. “AI helps simplify the navigation of global trade complexities.

“AI says, ‘Here are the three most likely disruptions in the next 10 days, and here’s your best set of mitigation actions based on cost, risk, and sustainability goals,’” Carrico adds. “It’s less about dashboards and more about actionable foresight that’s pre-integrated into workflows.”

8. Invest in Automated Technologies

AI agents are also reshaping supply chains, making it easier for shippers to switch from reactive analytics of complex operations to proactive decisions.

“Teams spend a lot of time juggling disconnected systems just to make decisions, especially during disruptions,” Ravindran says. “AI agents eliminate this by automatically connecting systems and handling routine coordination tasks.”

For example, a tracking agent monitors shipments 24/7, catches problems early, and coordinates with carriers. A supplier agent processes documents and chases missing information without human intervention.

“As a result, the traditional ‘war room’ response becomes unnecessary when agents can handle the coordination automatically,” Ravindran says. “AI agents work around the clock, scale instantly during disruptions, and learn from each situation.”

Adoption of AI-powered predictive analytics rose from 35% in 2024 to 45% in 2025 as companies seek to get ahead of potential disruptions.

“Those leading the way are investing in predictive analytics, AI-powered risk assessment, and automated alerts that allow them to adjust routes, anticipate delays, and mitigate risks before they impact operations,” Daigle says.

9. Get Visibility

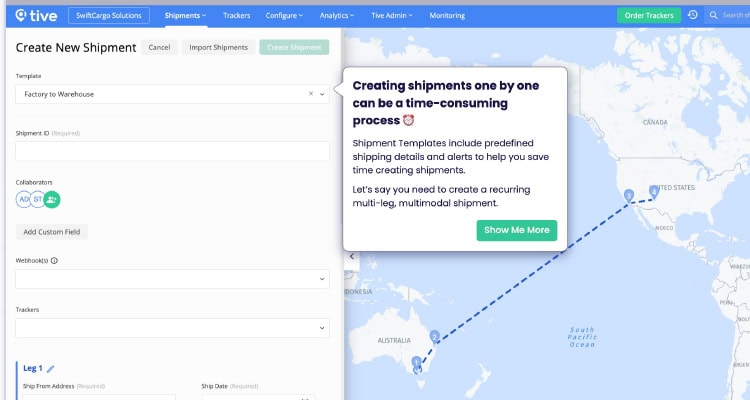

Many companies still lack visibility across their global supply chains, leaving cargo exposed to delays, theft, and damage. Supply chain platforms like Tive can help shippers easily create and track orders, enabling a full, real-time picture of their shipments in transit.

Visibility remains one of the most crucial supply chain elements—but also one of the sector’s greatest weaknesses.

“Companies have invested heavily in tracking, but many still don’t have a full, real-time picture of their shipments in transit,” Daigle says, noting that a recent report from Tive finds 37% of businesses still lack mid-mile tracking, leaving cargo exposed to delays, theft and damage.

“That means too many companies are reacting to disruptions instead of preventing them—leading to rejected shipments, lost revenue, and supply chain inefficiencies that could have been avoided,” he says.

For AI to be effective, it requires timely and comprehensive data that can be fed into its models. That makes Internet of Things (IoT) solutions more important.

“Beyond elevating real-time shipment awareness, IoT is quickly becoming a prime source of robust, timely, and reliable ground-truth data,” Daigle says. “This data is the foundation that elastic supply chains need to remain flexible and resilient during the industry’s pushes and pulls.”

Despite the necessity of tech solutions today, “technology alone isn’t the answer” in modern global trade, Daigle notes.

“The key is real-time situational awareness,” he says. “The companies that thrive in this climate can see disruptions unfolding as they happen and adjust in real time.”