7 Ways to Integrate Demand and Supply

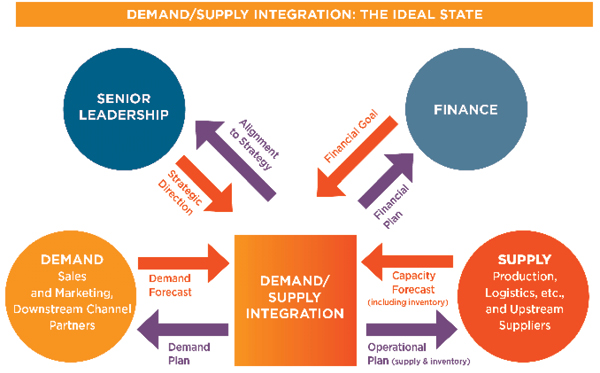

Companies can achieve cohesive demand and supply integration (DSI) by following seven fundamental rules, recommends a recent University of Tennessee Global Supply Chain Institute study. The paper, based on the work of Mark Moon, PhD, a UT professor and global supply expert, focuses on 18 companies in a range of sectors with successful DSI as a benchmark.

The seven strategies are:

1. Business-led DSI.

When a company’s business leadership incorporates DSI into all functions, the company as a whole thrives, and DSI becomes a central focus. "Benchmark companies said business leadership sponsorship was critical to DSI excellence," the report notes.

2. Continuous improvement culture.

Consistently and continuously assessing the DSI process is necessary in the ever-changing supply and demand environment. When a "multifunctional leadership team" is committed to learning, growing, and overcoming challenges related to the DSI process, a cohesive work environment across all departments forms.

3. Demand planning excellence.

The investment in and use of advanced analytics helps transition companies from "chasing forecast accuracy targets" to more accurate, regimented forecasting efforts led by technology, leadership teams, and service providers specializing in analytics.

4. Digitally enabled DSI

Advancements, which include machine learning, apps, and applied AI, all contribute to "the improved quality of decision making and the productivity of DSI planners."

5. Sustained DSI mastery.

DSI, along with its evolution and upkeep, must become ingrained in company culture. Empowering the process leaders creates value, and enables them to master DSI through continuous evaluation and assessment.

6. Focus on business intelligence.

Profit growth is often a direct result of seeing DSI as an important "source of business intelligence." More than just pinpointing forecasting mishaps to improve upon in the short term, DSI can be used to "improve the quality of future planning and execution" when viewed holistically.

7. Supply planning excellence.

Necessary in forecasting, quality, and investment decision- making, a strong supply planning procedure feeds healthy DSI. Supply planners with a background in both general planning and in supply planning performed best, according to the study.

The seven strategies do not follow any particular hierarchy and making them an integral part of the business model proves effective. "If these strategies become a part of a firm’s overall operating DNA, then the supply chain function and the sales and marketing functions no longer become adversaries," says Dr. Moon. "Rather, they become symbiotic elements of an enterprise, where all functions operate in synch to achieve overall organizational goals."