Choosing a Warehouse Management System: 3 Tips for the Right Pick

If you are in the market for a warehouse management system (WMS) provider, focus on your current business needs with an eye to the future. Here are the factors to consider and questions to ask to ensure you make the right choice.

The supply chain is changing, and along with it are warehouse management systems (WMS). As sophisticated technology transforms supply chains, WMS solutions don’t just strive to keep pace with progress; they also help drive new advances.

The selection process for a new WMS provider is marked by complexity and choices.

Into the Cloud

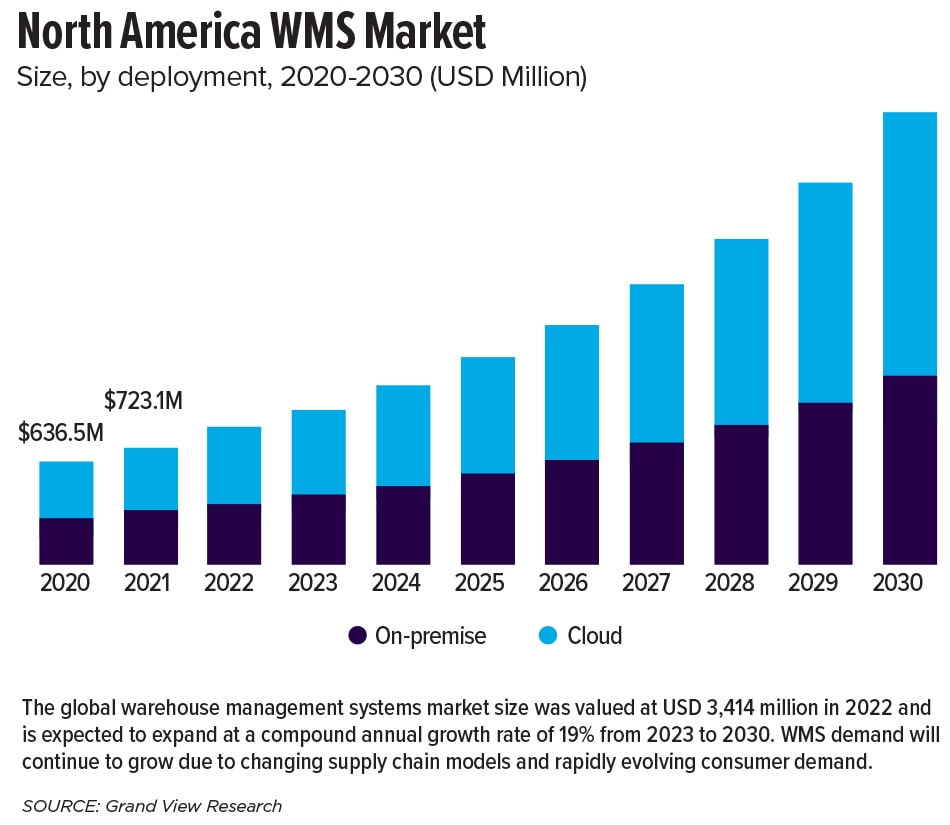

WMS applications have made “a monumental shift” from on-premise platforms to cloud-based solutions, notes Jim Brochu, general manager of supply chain for Pivotree, an IT service management company.

Meanwhile, companies continue to embrace real-time tracking and visibility that allows better inventory control while reducing errors.

Integrating artificial intelligence and machine learning algorithms allow a WMS to analyze large volumes of data and make intelligent predictions. “This helps optimize inventory management, improve order fulfillment and enhance overall operational efficiency,” says Amit Levy, executive vice president, sales and strategy for Made4Net, a WMS company based in New Jersey.

The rise of robotics and automation in warehouses also presents a challenge for WMS providers to integrate and orchestrate those technologies.

Generative AI is not just about automating jobs. “It’s making us smarter,” says Ann Marie Jonkman, senior director, global industry strategies, for supply chain management company Blue Yonder.

As the technology continues to progress, it will play a more prominent role—making it an important consideration for those shopping for a WMS.

There are many factors to consider when identifying the ideal WMS for your organization. Here’s how to get it right.

1. Focus on priorities.

It is critical that businesses shopping for a WMS make sure they “understand what it is they’re trying to accomplish,” recommends Dan Gilmore, chief marketing officer with Softeon, a Virginia-based software company.

The business case should drive the decision-making, evaluation, testing and “everything else,” he adds.

“In the end, it’s all about developing the business case,” Gilmore notes. “Analyze where the savings and other operational improvements will come from and then work backward: To achieve the return on investment and the results that we have promised, what WMS capabilities do we need?”

For example, “If we promised that we can improve labor productivity by 20%, where will that come from? Do we need to break it down by receiving, put-away, order picking, and shipping? It is important to tie the whole selection process to that initial business case.”

The WMS selection process starts with understanding your business needs, beginning with your organization’s requirements and goals.

“Identify the pain points in your current warehouse operations and determine the functionalities and features you need in a WMS to address those challenges effectively,” Levy says.

Narrow down your priorities based on feedback from stakeholders. Then identify core goals over the next 18 to 24 months and how a WMS can help work toward them.

Key questions such as whether you plan to open new facilities, expand your ecommerce efforts, or launch a new business line can help potential providers address your needs. “Focus on how their product adapts with what you have and where you are going,” Jonkman says.

“Look at the top two or three initiatives and align with the stakeholders, your business mix, and your service levels and business strategy,” she adds.

Some companies waste time evaluating WMS functions that are not critical for their operation, treating dozens or more line items as equal rather than narrowing the emphasis to six to 12 components that are truly critical.

“It’s important to identify the functions you need to focus on, and make sure the potential WMS can do those things and do them well,” Gilmore says. “That focus ripples through the request for proposal, through the dialog, and through the demos.”

2. Dig through the details.

The intricacies of WMS considerations boil down to three key dimensions:

- The implementation model. Is it installed within the four walls of an enterprise or on the cloud?

- The pricing model. Is it a large upfront licensed payment, a subscription contract, or a hybrid?

- The management model. Will the vendor manage the WMS or will your own team manage it? Different organizations have different preferences depending on their circumstances.

Narrowing Down the List

To create a shortlist of potential WMS providers, consider factors such as reputation, experience, customer recommendations, and industries served.

Reference checks can help gauge a vendor’s commitment to customer service. Ask existing customers of prospective WMS vendors about their experience with the system, the implementation process and ongoing support. “This will give you insights into the provider’s commitment to customer service and satisfaction,” Levy says.

A vendor who asks unique, compelling questions that help you think about your business more deeply offers promise as a strategic partner who can help strengthen your organization over the long term.

Companies should not miss an opportunity to have a dialog with vendors, particularly as the prospect list narrows. When companies have “a real discussion” with vendors about their goals, objectives, and business case, “they learn a lot and improve the project,” Gilmore says.

A scripted demo of solutions is a key decision-making tool in WMS selection. Companies shopping for a WMS should take time to ensure the demo is nuanced and specific to their needs.

“At the RFP level, vendors say yes to everything,” Gilmore says. “Even in the demo, a vendor might claim they have all the capabilities. But if you take it down a level to more detail, you will find out that there are some differences that wouldn’t show up otherwise.”

Many businesses face the question of whether or not to employ a WMS consultant for the selection process.

“Generally, if you have to ask that question, you probably should use a consultant,” Brochu says. “But you especially should if you don’t have enough information to forecast and understand what the actual costs will be.”

Beyond a product and its features, an organization should consider how a WMS vendor aligns culturally, weighing factors such as its mission and values, its approach to sustainability, and how it treats its team members. Also consider the big-picture question: Is this a company you want to do business with?

For instance, an enterprise that wants to be on the leading edge of technology will want to ensure its WMS vendor has a similar commitment.

A “subscribe now, buy later” plan is an option for companies not ready to make a full investment in a WMS. TouchPath, for example, offers a discounted subscription scheme for its TouchWMS warehouse management system.

3. Buy a solution for tomorrow, not just today.

A common and potentially costly mistake is selecting a WMS for the present rather than the future.

“Companies need the mindset that they’re not buying a product that solves today’s problems, but a platform for continuous improvement and process change over time,” Gilmore says. “Thinking about it that way changes the way you evaluate potential vendors.”

Investigating whether a WMS will align with a company’s future needs means analyzing if a system is configurable, scalable, flexible, and adaptable.

“Assess if the WMS can accommodate future growth—in users, business volumes, new warehouses—and seamlessly and easily handle changing business requirements, support new technologies, and integrate with other systems,” Levy says.

“Evaluating vendor roadmaps and customer testimonials, and requesting demonstrations or trials can provide good insights into the WMS’s ability to meet your future needs,” he adds.

Weigh the future goals of your business and how you plan to grow in the coming years.

“For instance, if you plan to implement advanced robotics in the next five years, and the WMS platform doesn’t support it or doesn’t have integrations to a leading vendor, maybe it’s not a match—even if they can knock it out of the park for you right now,” Brochu says. “At the very least, have a conversation with the vendor.”

Scalability and flexibility are essential characteristics to determine whether a WMS will likely remain a good fit in the future.

“It’s important to choose a WMS that can scale with your business as it grows,” Levy says. “Evaluate the system’s ability to handle increased order volumes, additional warehouses, and changing business requirements.

“Flexibility in terms of customization and adaptability to industry-specific processes is also crucial,” he adds.

In light of the rapid pace of progress, finding a WMS provider that can serve as a reliable partner who helps you navigate the changes ahead has never been more essential.

“It’s important that your company stays ahead,” Jonkman says, “or you will be left behind.”

When choosing a warehouse management system, be sure it can support future plans, such as robotics or other automation implementations.