Plastic vs. Wood Pallets: Key Differences and Comparisons

Pallets are flat platforms used as a base for storing, stacking, handling, and transporting goods and products. Their design allows for lifting by a pallet jack, forklift, or other material-handling equipment. This design facilitates the efficient movement of goods through the supply chain, enabling easy loading and unloading onto trucks, ships, and other vehicles.

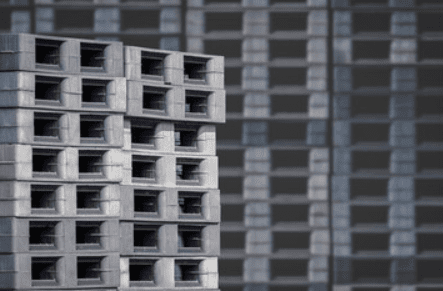

Plastic and wood are the two most common materials used for pallets. The choice between plastic and wood pallets often depends on specific needs, such as cost, durability, weight, and environmental impact. Let us look in-depth at plastic vs. wood and explore their differences.

Plastic Pallets

A plastic pallet is flat with rigid platforms made of plastic materials, such as high-density polyethylene (HDPE) or polypropylene (PP). These materials are known for their strength, durability, and resistance to moisture, bacteria, and other contaminants. You can also mold them into various shapes and sizes, and quickly clean and sanitize them.

Plastic is a durable, light, inexpensive, recyclable, and environmentally friendly material manufactured in almost any color. Plastic pallets are ideal for use in the food and pharmaceutical industries because they are resistant to moisture, bacteria, and other contaminants. However, they may become slippery when wet and may not be as strong as wooden pallets in certain conditions.

Plastic Pallets Advantages

Plastic pallets tend to have a longer lifespan. Plastics are solid and durable materials, such as HDPE or PP, that can withstand heavy loads, harsh conditions, and repeated use. It makes them an economical choice for many businesses requiring pallets with a longer shelf life.

Plastic pallets are resistant to moisture, bacteria, and other contaminants, due to their smooth and non-porous surface. They are also easy to clean and sanitize to maintain proper hygiene. This high level of hygiene helps reduce the risk of contamination and increases the safety of products transported and stored on plastic pallets.

Plastic pallets are often more cost-effective than wood pallets, especially in the long run, as they are more resistant to damage and can last for years. Many plastic pallets use recyclable materials, such as HDPE or PP, which helps reduce their environmental impact. Recycled pallets also lower costs as organizations avoid buying pallets over and over.

Plastic pallets are also lighter than wood and metal pallets, making them easier to handle and transport. The lighter weight reduces the risk of injury, increases efficiency, and makes them easier to stack, which can help save space and improve storage efficiency.

Plastic Pallets Disadvantages

Plastic pallets tend to crack or break under more weight, especially with repeated use. They may need to be replaced more frequently than wood pallets. Additionally, you cannot repair plastic pallets, so they must be replaced if they are damaged. Plastic pallets also bear a higher initial cost of purchase.

Production of plastic pallets requires significant energy and resources, contributing to greenhouse gas emissions and other forms of environmental degradation. Most plastic pallets are also non-biodegradable. They create a huge environmental issue as plastic waste can harm wildlife and marine life and pollute the natural environment.

Chemical concerns are another disadvantage of using plastic pallets. Some plastic pallets contain harmful chemicals that can leach into food or other products they come into contact with.

Wood Pallets

A wooden pallet is a hardwood pallet used for shipping and storing goods and materials. It consists of a flat deck supported by parallel boards or blocks known as runners. Wood pallets are flat platforms made of lumber, such as pine or hardwood, durable and long-lasting materials.

Wood pallets are often used in manufacturing, warehousing, and shipping, as they provide an efficient and cost-effective way to transport goods. They are stacked on top of each other and secured to ensure the load remains stable during transit. They are also easy to repair or replace if damaged, making them a popular choice for many businesses.

Wood Pallets Advantages

Wooden pallets are sturdy and can withstand heavy loads and harsh conditions, making them reliable for transporting fragile items. The strength of hardwood pallets comes from their construction, which consists of lumber. It is a robust and long-lasting material that can withstand rough handling and support heavy weights without collapsing or breaking.

Repairability is another advantage of using wood pallets. Unlike disposable materials like plastic, wood pallets can get repaired if damaged, giving them a significantly longer lifespan. It makes them an economical choice for businesses that ship products regularly, as they can continue to use the same pallets for an extended period.

Environmental friendliness is a significant advantage of using wood pallets. Wood pallets are biodegradable and can be recycled or repurposed after they are no longer used for transporting goods. It means they are eco-friendly and they do not contribute to the growing plastic waste problem.

In addition, producing wood pallets often involves using sustainable forestry practices, which help protect natural resources and conserve the environment. Many wood pallet manufacturers use responsibly sourced lumber harvested in a way that preserves forests and wildlife habitats.

Wood Pallets Disadvantages

Wooden pallets are often heavy and difficult to handle, making them challenging to move and manipulate. It increases the risk of injury to workers and makes the transportation process more time-consuming and labor-intensive. The weight of wooden pallets makes them more expensive to transport, as more fuel is required to move heavier loads.

They are susceptible to wear and tear from handling and transportation, breaking or becoming damaged more frequently than other materials. Additionally, wooden pallets absorb moisture, causing them to warp or rot, and they may be susceptible to mold. These conditions further compromise their structural integrity and affect the safety and security of goods during transportation.

Wooden pallets are attractive to pests such as termites, ants, and beetles, which can cause significant damage over time. It affects the pallets and makes them unsuitable for use, leading to replacement costs. They are also prone to storing bacteria as they aren’t easy to clean, which can affect the products on shipment.

Plastic vs. Wood Pallets by Industry

Different industries use different pallets based on their designs and specifications. Here are some examples of pallets used in various industries.

Food-Grade Pallets

Food-grade pallets are pallets designed and manufactured for transporting and storing food and food-related products. Plastic food-grade pallets should contain a safe, food-grade polymer pallet material that does not pose a contamination risk. They are easy to clean and sanitize, as they do not absorb moisture and bacteria.

Wood food-grade pallets must get treated to eliminate harmful chemicals and bacteria and meet strict cleanliness standards. They must also be cleaned and repaired regularly to avoid damage to products in transit and infestation by bacteria and insects.

Hygienic Pallets

Hygienic pallets are specialized plastic pallets designed for companies with strict hygienic requirements, like food, medical, and pharmaceutical industries. These pallets are resistant to bacteria, fungi, and other microorganisms and are easy to clean and sanitize. Hygienic pallets minimize the risk of product contamination and maintain high hygiene standards.

Industrial Pallets

Industrial pallets are heavy-duty platforms used in various industries to store, transport, and handle goods. These pallets are designed to withstand heavy loads, frequent handling, and harsh industrial environments. Industrial pallets are built to withstand daily use in industrial settings, such as factories, warehouses, and distribution centers.

They are stackable pallets, allowing for efficient storage and transportation of goods. Plastic industrial pallet material is durable, lightweight plastic material and resistant to moisture, bacteria, and other microorganisms. On the other hand, industrial wood pallets are cost-effective and offer a strong and durable solution for handling heavy loads.

Things To Consider When Choosing a Pallet Type

Here are some considerations before choosing a pallet type.

Price

Price is a significant factor when choosing the type of pallet for your operation because it affects the overall cost of materials and transportation. The cost of the pallet also depends on the quantity purchased, the availability of pallet material, and the manufacturer’s location. Businesses must balance the cost of the pallets against the frequency of use, the conditions in which pallets will be used, and their overall budget.

Purpose

Companies must consider the purpose when choosing a pallet type because different pallets are designed for specific services. The intent of a pallet, the weight, the size of the goods in transit, the environment in which you will use the pallet, and the frequency of use are all factors to consider when selecting pallets for your operation.