Precision Shipping: The Rise of Item-Level Visibility Solutions

Whether shipping fruit, pharmaceuticals, high-value commodities, or any other goods, solutions that precisely track individual items throughout their supply chain journey are becoming increasingly accessible and valuable.

Item-level visibility has become a must for shippers and their supply chain partners. The technologies that make that visibility possible are becoming more accessible, sophisticated, and broadly applicable as visibility tools evolve.

“Item-level visibility offers an array of benefits, but the primary, overarching advantage of supply chain visibility is the precision that it brings to shipments,” notes Richie Daigle, supply chain evangelist at Tive, a Boston-based provider of visibility solutions.

“Not only does visibility provide precise information about shipment location and arrival time, but it also offers detailed insights into the conditions of an item at any given moment,” says Daigle. “Shippers can monitor how hot or cold it is, how wet it is, and how it’s being handled.

“Additionally, they can see if doors, boxes, or other containers are being opened,” he adds. “This information gives shippers precise insights into both the location and the condition of a specific item at any point in time.”

That precision is exactly what today’s supply chain needs.

“The pace of everything is so much faster today, and it’s putting a lot of strain on the supply chain,” Daigle explains. “Companies have to be more precise with planning, inventory control, and sourcing. Everything has to be dialed in.”

What Drives the Need for Visibility?

Ambient IoT tags, like these from Wiliot, offer item-level real-time tracking and data collection that help satisfy consumer demand for faster shipping and supply chain transparency.

Several trends are driving the rise of real-time and item-level visibility.

“Ongoing regulations—such as food and drug traceability, including FSMA Rule 204, Digital Product Passport requirements, and provenance and circularity rules—lead to an increased need for item-level visibility,” says Steve Statler, CMO at Wiliot, an Israel-based provider of Internet of Things (IoT) technology. “And consumers continually demand faster delivery times for online retail, with transparency throughout the delivery process.”

In non-regulated supply chains, there is growing consumer demand for verifying a product’s authenticity throughout its entire lifecycle, from vendor sourcing to purchase.

“This is critical especially due to global manufacturing and distribution,” says Shyam Krishna, vice president of healthcare solutions for Softeon, a provider of supply chain execution and planning systems.

“Consumers like to know that even if they buy a generic brand laptop or cell phone, they can be assured that the motherboard or components can be tracked and traced for authenticity and reliability,” he says.

Consumers also want the ability to track assets and receive real-time alerts on factors such as a product’s shelf life or expiration, or its wear and tear, among other elements.

The widespread emphasis on supply chain resilience and the ability for retailers to quickly adapt to disruptions also have been factors driving demand for visibility. So has a shift toward omnichannel retailing and the need for precise inventory tracking across multiple channels.

In addition, sustainability’s increasing importance plays a role as brands better prioritize reducing waste and improving resource utilization.

Industries including food and pharmaceuticals, which have regulations requiring temperature monitoring to verify product conditions, are currently the most frequent users of IoT devices.

“Those industries are at the cutting edge of real-time item-level visibility, because they have to be regulated,” Daigle says. “We also see adoption within high-value freight.”

Key tech tools for item-level visibility include ambient IoT tags, which offer real-time tracking and data collection; advanced analytics and AI, which provide predictive insights and decision-making; and cloud-based platforms, which allow for scalable and flexible data management.

“Advancements in IoT and sensor technologies make real-time data collection more feasible and affordable,” notes Statler. “Supply chains also have seen an increased focus on AI, data-driven decision-making, and predictive analytics. With item-level visibility, these decisions can be made with significantly more data and legitimacy.”

When Visibility is ‘Real-Time’

Statler says that there’s a misconception that item-level visibility solutions are costly or complex to implement. He argues that these tools offer “significant” return on investment, effective scalability, and can be used for many applications across the supply chain.

Technologies such as IoT can be used to track packages, and can monitor item attributes, temperatures, and other conditions while shipments are in transit. They also integrate well with other tools.

“A warehouse management system integrated with a smart print-and-apply system can apply RFID labels in a high-volume shipping environment, thus making item-level visibility easily achievable,” Krishna says. “Essential attributes of the product are encoded easily into these smart tags.”

Devices placed on items before they ship record conditions as the shipment travels through the supply chain—yielding intelligence that can be used after they arrive. Once the shipment reaches its destination, workers can plug in the device and analyze the data to ensure that conditions during the trip were as they should be.

This retroactive data can be valuable. “The data may tell us a product needs to go into the trash if it would be damaging to a consumer,” Daigle says.

By contrast, real-time item-level visibility technology records information—temperature, humidity, shocks or light—in real time and the data is sent into the cloud. Recipients of the data can make decisions or adjustments based on that information.

For instance, if a refrigerated unit has an incorrect setting, the truck driver can be notified to make adjustments before products are ruined. “The difference is learning something after it’s too late versus saving a shipment with real-time information,” Daigle says.

While tracking assets such as trucks, trains, containers, vessels, and aircraft is effective, issues can arise. For instance, drivers may be non-compliant, or mix-ups can occur, leading to items ending up on different vessels.

“Having a device that is connected to the item itself cuts out all the noise and provides the single source of truth that shippers can rely upon to know what’s happening with the location and condition of that specific item,” Daigle says. “Item-level visibility from an IoT tracker gives shippers that redundancy.”

Boost Resilience, Combat Fraud

Among the most pressing priorities in the supply chain today are increasing resilience and combating rising fraud and theft. Item-level visibility can help build improvements in both areas.

“Track-and-trace workflows can be applied to item-level visibility solutions so the status of an item can be tracked in real time through the supply chain along with its attributes—lot code, expiration date, serial number—and also dispositions such as good, bad, returned, damaged, or recalled, ” Krishna says. “This makes the supply chain more resilient and helps combat fraud.”

Item-level visibility can also support resilience to “black swan events,” similar to ones the supply chain has recently faced: a pandemic, rebels in the Red Sea cutting off trade routes, and a ship running into a bridge in Baltimore’s harbor.

Raising Awareness

“These destabilizing events have created massive ripples throughout what was previously a well-oiled machine,” Krishna says. “Because supply chains have to move so quickly, and we demand so much of them, they’re also a bit fragile when it comes to these types of events. They’re not quite as resilient, which means technology has to help plug the gap.”

Item-level visibility contributes by raising awareness of the shipment location and condition, and that awareness can equip teams to quickly make informed decisions.

When it comes to combating fraud, item-level visibility solutions help in an assortment of ways.

“Visibility solutions support stronger security measures by providing detailed insights into the supply chain, allowing retailers to spot counterfeits and determine appropriate products,” Statler says. “Item-level and real-time visibility also enables early detection and responses to any potential disruptions, minimizing the impact of fraud on the supply chain. Visibility also enhances traceability, making it easier to track and verify the origin and movement of goods, thereby reducing fraud and counterfeit risks.”

Given the high level of data associated with item-level visibility solutions, there is also high risk of that information falling into the wrong hands. The right processes and resources are critical to mitigating risks associated with these technologies.

“Adherence to proper information security protocols reduces the cybersecurity risks and data breaches that can occur when these technologies are put to use,” Krishna says. “Improperly implementing these protocols can lead to easy cyber hacks and can compromise critical item-level visibility.”

Looking Ahead

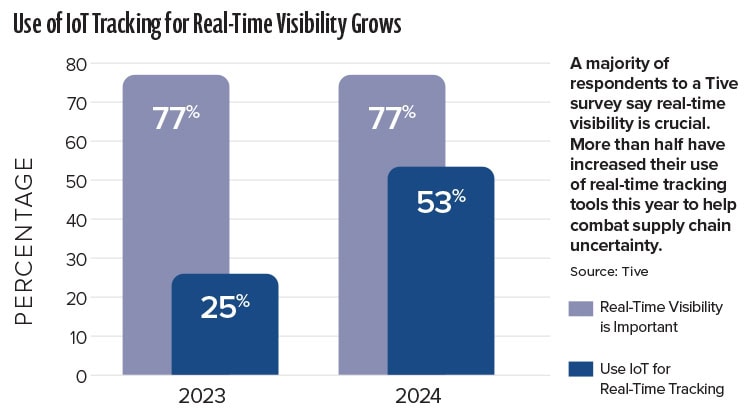

What’s next on the visibility horizon? Nearly 90% of respondents to Tive’s 2024 State of Visibility survey say that digital transformation of their supply chain and logistics operations is a major priority for this year.

“A lot of companies are revisiting their tech stack and plan to reevaluate the technology they have in place, and 75% of respondents say that real-time visibility is a key priority within their broader digital transformation efforts,” Daigle says. “Everybody recognizes the importance of awareness at the item level, and they see that IoT devices are one surefire way to stay in the know. Over time, like any other technology, components for these devices will become less expensive. As prices come down, adoption will continue to grow.”

Ambient IoT is now baked into standards for Wi-Fi, cellular, and the next generation of Bluetooth. And new data standards, such as GS1 Digital Link and EPCIS 2.0, enable more robust information to flow throughout the system.

Item-Level Expansion

“These advancements will likely allow for end-to-end data visibility, from manufacturers to consumers and back upstream to the manufacturer,” Statler says. “Item-level visibility will likely expand into new industries and applications, driven by continuous advancements in sensor technology and data-processing capabilities.”

The greatest challenge to strengthening item-level visibility is improving trust and openness to data sharing throughout the supply chain ecosystem. “It is essential for manufacturers, retailers, and consumers to fully realize the benefits of item-level visibility,” Statler says.

“To increase trust, the industry should continue to focus on data privacy and security, which are crucial as the adoption of item-level visibility solutions grows,” he adds. “And to scale effectively, the industry needs new enterprise applications that support item-level visibility. The old systems need to be rewritten.”

The strategic uses of IoT and item-level visibility are only going to grow. “In the long term, we’ll see a transition from the combined application for tactical usage eventually moving into a strategic application where the devices are the single source for aggregated data—especially with AI coming on board,” Daigle says.

“AI and machine learning algorithms are only as good as the data fed into them,” he adds. “As companies begin to see IoT devices as a source of high-quality data, they will be able to extract much more value from that data. It’s exciting to see how that all plays out in the coming years.”