Building the Supply Chain Tech Stack

Why supply chain leaders must stack their tools wisely—and how the right configuration can boost visibility, efficiency, and control.

The rapid evolution and growing complexity of supply chain technology in recent years makes it increasingly important for companies to prioritize building and managing their tech stacks to ensure optimal effectiveness.

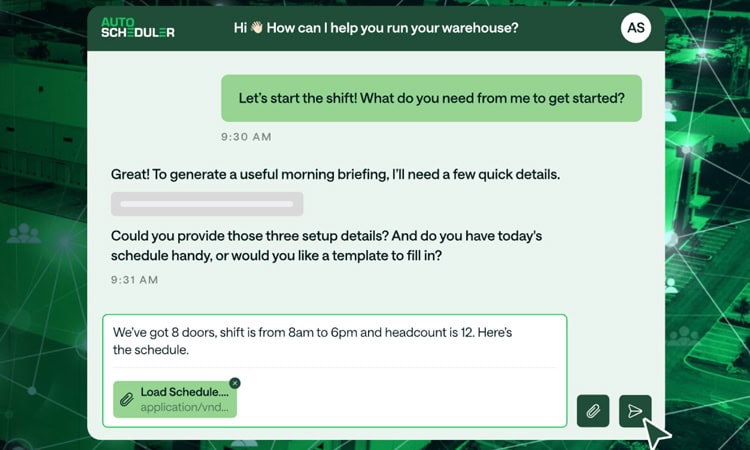

“The old trope about people, process, and technology being the three staples of supply chain has never been more true,” says Keith Moore, CEO of AutoScheduler. “In fact, as processes change quickly and skilled people become harder to find, having a foundational technology stack for capturing both data and tribal process knowledge becomes all the more critical.”

Among other things, a strong technology stack allows logistics, supply chain, and procurement teams to work smarter—not just harder—at a time when inefficiency can be more costly than ever.

“When teams are bogged down with manual tasks, or constantly switching between systems to access data, it slows everything down and increases the risk of errors,” says Anders Lillevik, founder and CEO of Focal Point.

“The right tech eliminates inefficiencies by automating repetitive tasks and centralizing key information in one place,” Lillevik adds. “It also improves visibility across the organization, which is critical for making quick, informed decisions.”

Transparency, speed, and accuracy are key benefits. “And just as important, you enable teams to shift their focus from low-value tasks to more strategic work, such as supplier management or cost optimization,” Lillevik adds. “That kind of shift has a big impact on both the top and bottom line.”

Today’s supply chain tech stack should be designed for modularity so companies can constantly revisit what’s working and optimize the stack for their operation. This flexibility enables users to take advantage of new and evolving solutions, including AI agents like this one from AutoScheduler, which can help improve labor efficiencies.

Basics of an Effective Stack

Distribution-centric organizations feel pressure to improve service levels and be cost competitive, which drives the need for increasing automation in their fulfillment networks. “As automation increases, the tech stack becomes even more critical,” says Jim Barnes, CEO of enVista.

But tech stacks are not one-size-fits-all solutions. The most effective technology stack for a supply chain differs based on industry, velocity, and footprint. However, most technology stacks revolve around the enterprise resource planning (ERP) system, which merges transactional sales data with inventory availability and movement.

“It’s important to build out the right execution systems around an ERP to enable a business to maximize service and maintain agility and resilience,” Moore explains.

Warehouse management systems (WMS), warehouse execution systems (WES), warehouse control systems (WCS), and labor management systems (LMS) are the supply chain execution solutions that serve as “the building blocks within the four walls,” Barnes says. WES+, the advanced warehouse execution system, is rising in importance.

Technology that supports item master, pricing, inventory management, and master data management is table stakes for supply chains centered on manufacturing, distribution, or retail.

“Because ERP systems aren’t designed to manage inventory complexity across multiple channels, omnichannel retailers need robust tech stacks that can fill in that gap and provide a single source of inventory truth,” Barnes adds.

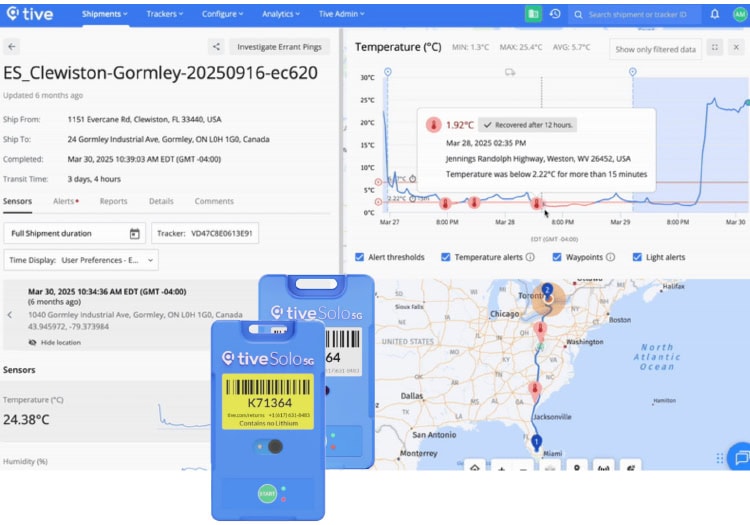

The best stacks start with reliable data, tight integration, and redundancy. “Trustworthy data is vital,” says Colby Aaron, director of sales for Tive. “You need continuous insight into where a shipment is, how it’s being handled, and whether anything looks unusual.”

Just as important is making sure systems connect. When a TMS, WMS, visibility tools, and sensors operate separately, they create blind spots. Integration is what allows teams to move from simply monitoring shipments to preventing problems.

A warehouse management system (WMS) is a core building block for the modern tech stack, helping to improve performance inside the four walls. The Latitude WMS from PathGuide Technologies, for example, offers real-time tracking, intuitive dashboards, and scalable features that enable users to streamline inventory control and boost accuracy.

No Single Point of Failure

Redundancy also plays a critical role by reducing the risks that come with relying on a single device or data stream.

“The most secure supply chains layer external trackers, hidden internal trackers, sensor signals, and carrier verification,” Aaron says. “If one layer fails or is removed, another kicks in. The goal is simple: no single point of failure.”

In addition, tech stacks should be modular, highly customizable, and quickly adaptable to changing needs and environments. “Providing faster service times at a lower operating cost is a given requirement for any supply chain solution,” says Greg Laycock, vice president of software engineering for PathGuide Technologies.

“The right technology stack meets this requirement but also allows for customizing solutions tailored specifically to company and industry needs, improving the overall customer experience,” he adds.

Should You Build or Buy?

One of the first steps for companies putting together a supply chain tech stack is to determine their main challenges and whether they will build or buy their solutions.

“Deciding between buying technology, building technology, or a hybrid of the two is a critical business decision,” Barnes says. “The decision comes down to technology support, total cost of ownership, and operational complexity.

“For example, it’s common for 3PLs to own their WMS since they need to be agile and less dependent on a software vendor for code changes,” he says. “It’s also common for software vendors to allow for extensions, enabling the third-party software vendor to develop and license core system architecture.”

Companies should also document their current requirements and what challenges they are likely to face in order to evaluate which solutions best fit their needs.

“It is hard to predict what is coming around the bend, as the past 10 years have shown us, but it is important to anticipate the next three to five years,” Lillevik says. “It is also important to take another step back to look at the underlying processes the technology supports.

“If there is a logical reason to streamline, shorten, or reduce complexity in your processes, you should look for your technology providers to be able to support these desired, to-be processes,” he adds.

Companies also need a full understanding of their current technology landscape. Questions they should ask include, “What technology is working? What is not working? Where are the real gaps both with current and potential future requirements?” Lillevik says.

“Understand where your different technologies may have overlapping functionality and why one solution was chosen over the other in those cases,” he advises.

Investing in a tool without understanding whether it meets the organization’s actual needs is one common mistake. This can result in a mismatch between the solution and the problem.

“I’ve seen companies buy intake or orchestration tools because they think they need one, for example, but they never step back and ask what functionality they actually require,” Lillevik notes.

Limiting Fraud and Theft

A strong tech stack provides companies with a clear picture of what’s actually happening across the supply chain. This visibility is key to fight increasing cargo fraud and theft.

“When real-time location, condition data, authentication, and planning systems all work together, teams can spot problems earlier, verify drivers and handoffs, and react before a small discrepancy becomes a six-figure loss,” Aaron says. “Without that foundation, every process—routing, scheduling, carrier management, customer updates—is built on guesswork.”

However, because many companies still operate with outdated visibility tools, teams see only static or delayed updates. Cargo thieves take advantage of that lag to reroute freight or tamper with loads without being detected.

“Many companies also underestimate the value of real-time sensors and digital tamper seals,” Aaron adds. “These are no longer optional. They provide the earliest indicators of risks such as door openings, light exposure, unexpected stops or route shifts, and give teams the time they need to intervene before a loss occurs.”

In addition too many shippers rely on visible devices attached to trailers or packaging for tracking. These devices can be easily removed.

“True resilience comes from layering internal and external tracking with real-time sensor data to eliminate blind spots and ensure continuous monitoring,” Aaron notes.

As cargo security concerns grow and the threats become more complex, freight fraud platforms have increased in prominence, and are frequently being used to complement a robust tech stack.

“These tools help verify carriers, flag abnormal pickup patterns, and detect identity-based risks,” Aaron says. “When combined with real-time visibility and monitoring, they allow companies to identify suspicious activity much earlier in the process.”

Experts agree it is essential to ensure that various tools in a tech stack will work together and allow for the addition of new systems.

Keeping Connectivity in Mind

“When making buying decisions, focus on interoperability and ease of integration as one of the decision criteria,” Moore advises. “It’s easy to find a solution that can do what you want, but it’s never worth doing it at the expense of blocking future progress.”

Prioritizing interoperability from the beginning is a good approach.

“The easiest way to create friction is to buy tools that solve narrow problems but cannot talk to each other,” Lillevik says. “Supply chain touches systems across finance, legal, IT and operations, so whatever you implement needs to fit into a broader ecosystem.”

That means looking for tools that are built with connectivity in mind—open APIs, flexible integrations, and centralized data models, for instance. The goal is to enable workflows that move smoothly across systems and teams and to avoid creating more silos.

“When your tools are aligned, you gain speed, clarity, and the ability to scale without reinventing the wheel every time,” says Lillevik. “Make sure that the solutions do more than simply move the work from one system to another but rather add value along the way.”

With warehouse automation evolving rapidly, another consideration for a tech-stack build is creating capacity for future evolutions.

“Some automation equipment being deployed today did not exist even just a few years back,” says Suneel Krishnaswamy, CTO at enVista. “To keep up with this rapid development, technology and architecture needs to accommodate plug-ins to orchestrate yet-to-be-developed automation. This is where well-architected warehouse execution systems come in.”

While long-term future proofing is nearly impossible as technology continues its rapid-fire advance, companies can still enable their tech stacks to flex and adapt as new solutions emerge.

“Designing for modularity is critical so you can constantly revisit what’s working and optimize your tech stack for your operation,” Moore says.

Simply chasing the latest thing is not the right approach. “Future-proofing is about investing in systems that evolve with you and continue to deliver value as your business changes,” Lillevik says.

“Technology that was considered advanced years ago may no longer be relevant in the future,” he adds. “What matters is not how many tools you have, but whether they help you make better decisions, faster—and that they can evolve with your business. Look for solutions that are grounded in process, integrate, and support your teams with the right data at the right moment.”

How AI enhances WMS and TMS Functionality

Within the modern tech stack, artificial intelligence plays a key role in today’s WMS and TMS solutions.

“In a TMS, key AI components are being used within last-mile delivery to help measure and monitor real-time traffic patterns and delays,” says Jim Barnes, CEO of enVista. “Machine learning is being used in WMS order profiles to release work within a distribution center operation to meet service-level agreements.”

Since a company’s order profile does not remain constant throughout the year—or even sometimes through the day—AI solutions that can auto configure or adapt to changing conditions will be necessary to ensure optimal throughput for the warehouse.

“A solution that can allocate labor to appropriate tasks without manual intervention will be key to running a ‘manage by exception’ type of warehouse,” says Suneel Krishnaswamy, CTO of enVista, citing as examples AI’s ability to automatically prioritize cycle count or re-warehouse tasks when order volume is low.

AI also helps warehouse and transportation systems predict and adapt in real time, thereby making those systems smarter.

“In WMS, AI can help with dynamic slotting, demand forecasting, and inventory optimization,” says Anders Lillevik, founder and CEO of Focal Point. “In TMS, it can improve route planning, identify delays, and recommend better carrier choices.

“The real value comes from turning massive volumes of data into actionable insights,” he says. “Instead of relying on spreadsheets or lagging reports, teams can make decisions based on live conditions.”

AI does not replace human judgment, but it absolutely improves it, Lillevik adds: “It helps identify patterns and opportunities that would be easy to miss otherwise. That makes operations more responsive, resilient, and cost-effective.”

Warehouse Tech Tips: What Comes First?

Many growing organizations ask the question: What do we implement first, a labor management system (LMS) or a warehouse management system (WMS)?

The answer isn’t always the same, says Brian Carlson, founder of Cornerstone Edge. The right choice depends on your business priorities, data readiness, and growth plans. Carlson shares 10 tips to help you decide which system to add first to your tech stack.

1. Start with your business goals. Decide what’s most urgent: labor efficiency or inventory control. If labor costs are your biggest pain point, an LMS may be the right place to start. If accuracy, visibility, and throughput are your top priorities, a WMS might come first.

2. Understand the functional differences. A WMS manages product flow—directing inventory, tracking orders, and ensuring accuracy. An LMS manages people—measuring productivity, setting performance standards, and optimizing labor. Together, they create a complete picture of your operation.

3. Assess your available data. An LMS requires transactional data (task times, activity tracking). If your operation doesn’t already have that data, a WMS may need to come first to generate it.

4. Consider your company size and complexity. LMS implementations deliver the biggest impact in larger operations (100 to 150+ employees) with high variability and complex layouts. Smaller or less complex operations may see greater benefit from tackling WMS first.

5. Evaluate implementation timelines. LMS projects often have shorter timelines and quicker ROI—if the right data exists. WMS projects can take longer but provide a foundational platform for broader operational improvements.

6. Look at ROI potential. If your operation is labor-heavy, the ROI from an LMS can be immediate. If inefficiencies are tied more to order accuracy, visibility, or process control, a WMS is more likely to deliver a stronger return.

7. Weigh integration needs. Both systems eventually need to work together. Consider how integrations will play out. Implementing one system before the other may mean building connections twice if upgrades are planned later.

8. Factor in operational impact. An LMS rollout impacts people directly—it requires communication, collaboration, and buy-in from the workforce. A WMS changes daily workflows and processes, requiring retraining and strong operational change management. Both require careful planning, but in different ways.

9. Don’t fall for misconceptions. There’s no “universal right order.” Many assume WMS must always come first, but if the right labor data exists, an LMS can be implemented quickly and start paying off before a WMS is ready.

10. Roadmap for the bigger picture. Whether you start with LMS or WMS, think ahead. Build a roadmap that accounts for sequencing, integration, and future growth. The best choice solves today’s pain points while preparing you for tomorrow’s success.