Generation AI: Preparing for the Future of Supply Chain

Here’s how companies are developing the workforce of the future and how current practitioners can future-proof their careers.

Reframing Logistics for Gen Z and Gen Alpha

By Troy Lester

By Troy Lester

CRO and Co-Founder

Warp

I chose to go into logistics because I love delivering the experience of getting “what you want, when you want it” in the real world. But the logistics industry is at a crossroads. The old way, i.e., long hours, relentless pressure, and high turnover, is unsustainable. But a new path is possible. By embracing technology, aligning with the values of younger generations, and reframing what a career in logistics represents, the industry can transform itself into a profession of choice. Here’s how:

1. Tell the story differently

- Recast logistics not as “operations” or “manual labor” but as a sector defined by technology + problem solving + global impact.

- Position logistics as a hub for robotics, automation, AI, and data science applications—from warehouse robotics to AI-driven route optimization.

- Partner with schools and STEM programs to highlight logistics as an applied tech career path, not just manual labor. Meet Gen Alpha where they are on digital platforms such as YouTube, TikTok, Discord, and Roblox, with engaging content about careers in logistics.

2. Connect to purpose and impact

- Highlight logistics’ critical role in sustainability (e.g., optimizing routes to reduce carbon emissions, adopting EV fleets, and building greener warehouses).

- Showcase the human impact: delivering the food, medicine, and essential goods that keep communities safe and functioning.

- Rebrand logistics roles as part of “moving the world forward,” appealing to Gen Alpha’s desire for meaningful, value-aligned work.

3. Lean into Generation Z & Alpha work values

- As logistics digitizes, highlight roles in AI monitoring, cybersecurity, supply chain analysis, and digital twin management, many of which can offer partial remote flexibility.

- Flexibility and a blend of physical/digital work will appeal to Gen Alpha’s expectation of the workplace.

- Prioritize diversity, equity, and inclusion, and showcase diverse leadership. For these younger generations, this isn’t a nice-to-have, it’s a baseline requirement.

4. Think outside the box to recruit and retain talent

- Use gamification, AR/VR training, and simulation platforms to onboard and upskill employees. For a generation raised on interactive tech, this makes training engaging and relevant.

- Promote logistics challenges (e.g., hackathons, robotics competitions, supply chain simulations) to attract young problem-solvers.

- Create clear career pathways where entry-level workers can grow into robotics technicians, data analysts, supply chain strategists, or sustainability officers.

Attracting the Next Generation of Drivers

By Alex Proteau

By Alex Proteau

CTO and Co-Founder

Dispatch Science

While demand for delivery services continues to surge, the pool of qualified drivers is shrinking. Fleets across North America are grappling with a persistent driver shortage, and traditional recruitment strategies, such as higher pay, better benefits, and flexible schedules, are no longer enough. To attract the next generation of drivers, companies must consider the drivers’ digital experience.

Younger drivers entering the workforce have grown up with smartphones and intuitive apps. They expect smooth, responsive digital experiences. Unfortunately, many fleet operations still rely on outdated legacy systems that frustrate drivers with clunky workflows, poor visibility, and manual paperwork.

Cloud-first transportation management systems have driver apps that are as user-friendly and responsive as the apps people use every day, with real-time notifications about assigned jobs, priority changes, and delivery updates. They offer optimized stop lists, turn-by-turn directions, and instant access to delivery details.

Using Technology to Build Trust and Transparency

Modern systems that provide real-time information on route performance, delivery exceptions, and feedback loops help create clarity. When drivers see how their work connects to the bigger picture and feel confident that delays or issues are being communicated clearly, they’re more likely to feel invested. Cloud-based platforms enable this real-time coordination, connecting carriers and shippers regardless of backend setup.

Ultimately, the hidden factor that helps fleets attract next-gen drivers is a culture of innovation. Drivers want to work for companies that invest in technology and prioritize user experience. This doesn’t mean layering on flashy tools or automating everything; it means building systems that work with people, not around them.

Engaging the Supply Chain Workforce

By Andrew Billings, Sr.,

By Andrew Billings, Sr.,

Managing Director, Supply Chain

North Highland

The supply chain workforce has undergone a dramatic shift over the past four years—from the post-pandemic talent deficit to today’s unprecedented demand for record-breaking workforce productivity. Leaders face a key challenge: sustaining workforce programs that built resilience during the talent crunch while addressing urgent cost pressures.

Developing Performance Coaching Programs

As productivity becomes a key differentiator, leading supply chain networks are reviving coaching programs with renewed focus. These efforts center on three key elements:

1. Coaching for all. Coaching programs must support every associate, not just underperformers. When coaching is reserved for corrective action, it fails to inspire. Think of it like pro sports: Even all-stars benefit from spending 1:1 time with their manager or position coach on how to improve their performance.

2. Specific, actionable feedback. Leaders must invest time observing each associate perform their job, understanding how they execute tasks (methods) and how frequently they perform those tasks (utilization). Specific guidance tailored to an associate’s unique role drives improvement.

3. Leveraging data. Coaching sessions provide only a snapshot into an associate’s performance. To maximize impact, leaders must supplement real-time observations with high-fidelity performance data. Leveraging trends from labor management systems (LMS) or similar platforms allows leaders to provide data-backed recommendations that resonate with associates and guide impactful change.

Giving Performance-Based Bonus Incentives

Increasing wages as a cost-saving measure likely sounds counterintuitive, but that is exactly what leading distribution companies are doing.

While performance-based pay is not new, we are seeing a renaissance in this approach, driven by several factors:

- Advancements in data infrastructure: Decade-long investments in LMS and engineered standards now enable timely and accurate visibility into performance at the individual associate level.

- Speed and scalability: Unlike some robotics or automation upgrades, which can take years to implement, performance-based bonus programs in distribution environments can be implemented 3-5 times faster.

- Market expectations: Similar performance incentives are becoming table stakes in competitive labor markets, with job candidates increasingly asking about these programs.

However, performance-based incentives epitomize “easier said than done” in the distribution industry. As one Fortune 500 retail chief supply chain officer puts it, “We only get one chance at this—we have to get it right.”

While program specifics must be tailored to each company, successful ones share several guiding principles:

- Keep it simple. Incentive payouts should be easy to understand. If calculating a bonus requires multiple spreadsheets, it’s over-engineered and will cause confusion.

- Make it accessible and motivating. Ensure 30-50% of associates can achieve incentives, with top performers earning 10-20% of their base wage.

- Pay out frequently. Payouts every 2-4 weeks sustain engagement and momentum.

- Create win-win outcomes. Productivity gains should benefit both the employer and the employee. When structured properly, these programs become part of the cultural foundation of the supply chain.

Vehicle Logistics: Bridging the Skills Gap

By Justin Newell

By Justin Newell

CEO

INFORM North America

Vehicle logistics is inherently complex, with every car moved from plant to dealer subject to multiple processing steps, transport modes, and yard conditions. Skilled operators develop a mental model over the years—knowing how to reroute around delays, how to prioritize vehicles under tight service level agreements (SLAs), and how to coordinate terminal movements with minimal idle time. As fleet owners and 3PLs struggle with labor availability and retention, this tribal knowledge can become a knowledge gap.

Capturing Tribal Knowledge with Decision Intelligence

Decision intelligence platforms can help. Unlike traditional process automation, decision intelligence platforms use AI, optimization algorithms, and rules-based reasoning to guide decision-making dynamically. Critically, these systems are not just about efficiency—they’re onboarding tools. They function like digital mentors: providing task-specific guidance based on best-practice logic. AI can assist in scheduling and resource allocation, ensuring tasks are prioritized effectively, and technicians are utilized optimally.

Replicating Expertise at Scale

Decision intelligence can play a critical role in strategic planning. A case in point is Toyota Logistics Services (TLS) in North America. Facing growing complexity across its national vehicle distribution network, TLS turned to a network optimization solution. The platform enabled TLS to simulate multiple scenarios based on cost, carrier capacity, emissions, and other key SLAs like delivery times, providing the best and second-best routing strategies across 58,000 possible carrier-route combinations. While navigating supply volatility, it cut annual cost by 3%, improved service predictability, and aligned with sustainability goals.

How to Manage AI

“Approach artificial intelligence with curiosity and enthusiasm. Try it and keep learning. You won’t get it the first time, so you need repetitions. And finally approach with caution. I look at AI as an incredibly resourceful, yet overconfident colleague who tends to be 60% accurate and 100% confident.”

Matthew Kulp

EVP, Managing Partner

St. Onge Company

“The next generation of procurement and supply chain work will be defined by how well humans and AI collaborate. As AI agents take on routine execution, people will have more time to think strategically and drive creative, cross-functional initiatives.

A category manager, for example, could shift from managing purchases to co-creating new solutions with suppliers that drive growth and sustainability. Success will depend on reskilling teams to interpret data, guide agentic automation, and connect insights across the business. The future workforce will combine technical fluency with curiosity, creativity, and judgment—creating supply chains that are faster, smarter, and more innovative.”

Timothy Harfield

Head of Product Marketing,

ORO Labs

Tips for Young People Entering SCM

“My advice would be to go for it—there’s so much opportunity for young people to make a difference. The dynamic nature of the supply chain industry creates meaningful space for growth and innovation. With this evolving industry, there is increasing demand for diverse perspectives and new approaches.

This provides an opportunity for the next generation of supply chain professionals to recognize their unique value and to make an impact. While there is still room for improvement in terms of representation, the path is widening—and young people are essential to shaping the industry’s future.”

Maggie Turner

EVP of Logistics

RJW Logistics Group

“Be curious about everything. Ask ‘why’ when processes break down, ‘what if’ when exploring solutions. Supply chains need professionals who understand both technical mechanics and human elements. Use your knowledge and experience to make informed decisions. Make informed decisions quickly, learn from failures fast.

And lastly, lead through influence, not title. Your curiosity drives learning, learning leads to decisiveness which enables action, and relationship-building creates influence for change beyond formal authority.”

Tara Buchler

Principal, Strategy

JBF Consulting

Predicting the Future

“By 2030, technology will reshape nearly every part of supply chain management. Self-driving trucks, IoT-enabled assets, satellite connectivity, and AI will play major roles in how we plan and execute logistics.

But at its core, the role won’t disappear, but evolve. Supply chain managers will still be risk managers and problem solvers, just with far more advanced tools at their fingertips. The biggest difference will be how much real-time data and automation they will have access to for making faster, smarter decisions. In short, the fundamentals stay the same; it’s the toolbox that changes.”

Milton Feliciano

Vice President of Information Technology

iGPS Logistics

Also check out: The Future of the Supply Chain Manager Role

The bottom line: AI won’t make supply chain managers obsolete, but will elevate their importance. The repetitive tasks that have defined the role will be automated. What’s left is the higher-order work: problem-solving, strategy, and leadership.

Cultivating Young Talent

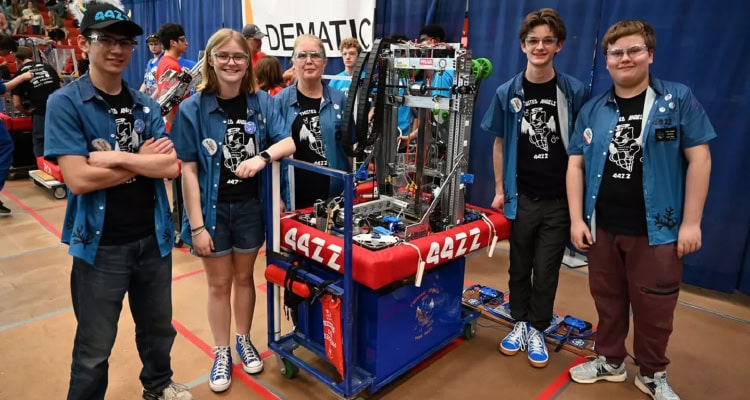

Supply chain automation company Dematic invests in the next generation of supply chain and logistics professionals by supporting hands-on problem-solving in schools and helping young scholars.

Dematic partnered with the Captain Planet Foundation, a nonprofit dedicated to engaging and empowering young people to be problem solvers for the planet, to bring hands-on Project Learning Gardens to students in two communities: Grand Rapids, Michigan, and Keller, Texas. The organizations brought outdoor learning spaces to Hidden Lakes Elementary in Keller, Texas in May 2025 and West Oakview Elementary in Grand Rapids, Michigan in August 2025.

Each installation transformed part of the school grounds into an outdoor classroom where students build and plant raised garden beds. By integrating these experiences into the school day, the program connects traditional educational lessons with hands-on learning in science, gardening, nutrition, and sustainability.

The Project Learning Garden program has reached more than 750 schools across the United States. Dematic has partnered with Captain Planet on the Project Learning Garden initiative since 2023.

Dematic also provides scholarships to support rising talent in science, technology, engineering, and mathematics (STEM). In August, the company honored 12 students who received its 2025 Dematic FIRST Scholarships. The annual scholarship recognizes students who have demonstrated exceptional potential and a passion for innovation.

Now in its fifth year, the Dematic FIRST Scholarship program receives applications from aspiring STEM leaders across the United States and Canada. A panel of Dematic leaders evaluates applicants based on their academic strength, creativity, and dedication to shaping the future of science and technology.

GEODIS Embraces Next-Gen Labor Tool

Global logistics provider GEODIS launched a new labor management system (LMS) to bring real-time visibility into workforce effectiveness and cost to serve. In collaboration with Easy Metrics, GEODIS started implementing the Easy Metrics LMS, built on the ProTrack technology foundation, in 90 of its facilities in the Americas. The next-gen solution allows operational teams to forecast labor needs, align teams with fair standards, and drive profitability.

GEODIS sought to upgrade from older LMS solutions that relied on teammates for manual analysis. With the Easy Metrics platform, GEODIS can boost engagement and productivity within its teams and across its operations.

For example, GEODIS engages its teammates and leaders through its Pay-for-Performance (PFP) program and Productivity Pyramid. The PFP program offers teammates an opportunity to earn extra weekly pay for good performance. Measuring operations as a whole, the Productivity Pyramid evaluates seven key areas including labor productivity, engagement, inventory accuracy, safety, process adherence, LEAN/Six Sigma results, and daily habits.

CMA CGM Develops Future Leaders

At TANGRAM, CMA CGM Group’s learning and innovation center in Marseille, France, 3,235 employees from 119 nationalities have completed tailored learning programs focused on artificial intelligence, climate, and leadership since the center was launched in 2024.

TANGRAM recently added eight learning programs, including a leadership program with Berkeley Executive Education, to teach individuals how to inspire high-performing teams and lead large-scale transformations. In addition to leadership skills, the new programs cover AI, decarbonization, sales, transformation, team, and individual development. For example, two strategic programs include: 1) artificial intelligence, which teaches participants how to understand AI opportunities and challenges, and foster AI adoption and culture; and 2) decarbonization, which lets learners engage with low-carbon frameworks, and shift mindsets on sustainability and Net Zero.

In its second year, TANGRAM looks to increase its impact, with 8,000 learners from 120 nationalities set to participate across its programs—with 45% women.