IoT Manufacturing: Components, Benefits, and Challenges

Factories are no longer just metal, noise, and manpower. Smart machines now collect data, talk to each other, and help manufacturers make faster, better decisions. Welcome to the age of IoT manufacturing, where efficiency and insight come from connected technology.

Across the manufacturing industry, companies use IoT devices and smart sensors to track machines, boost equipment efficiency, and avoid unplanned downtime. These tools give real-time data that strengthens the supply chain and powers smarter data-driven decision-making every day.

What Is IoT Manufacturing?

IoT manufacturing means using IoT devices, software, and network technology to connect machines, tools, and systems in a factory. These systems work together to collect data, share it instantly, and act on it, without human involvement.

Manufacturing companies use IoT sensors, connected devices, and cloud computing to track every step of the production process. Data from machines helps teams improve operational efficiency, reduce machine downtime, and respond faster to issues on the manufacturing floor.

Inside a smart manufacturing setup, machines constantly share real-time data. That information supports predictive maintenance, faster decision-making, and streamlined manufacturing operations across the board. Industrial IoT bridges the gap between the digital world and physical factory systems.

Core Components of IoT in Manufacturing

IoT systems work through a mix of hardware, software, and connectivity. Each part plays a role in helping factories run smoother and smarter. The following are the key components:

Sensors and Devices

Embedded devices with IoT sensors monitor machine conditions in real-time, tracking metrics like vibration, pressure, temperature, and movement. These smart sensors detect abnormal patterns before failure occurs. Early alerts prevent damage and reduce downtime.

By reducing reliance on manual inspections, factories gain stronger quality control. Accurate sensor input supports industrial internet applications that improve every step of the manufacturing process, from assembly lines to complex production processes.

Connectivity and Networks

Factory systems rely on Wi-Fi, 5G, Bluetooth, or LPWAN to transmit device data from machines to cloud platforms. Stable connectivity supports uninterrupted real-time monitoring, enabling quicker reactions and fewer delays.

Reliably connected sensors help manufacturing companies link multiple machines across large sites. Whether in smart factories or legacy facilities, network reliability allows seamless data exchange, smooth coordination, and tighter control over operations across the entire supply chain.

Data Processing and Cloud Platforms

Cloud computing and edge computing process vast amounts of IoT data collected by devices. Edge systems analyze data closer to where it’s generated, making reactions faster and more localized. Cloud tools help store, clean, and organize historical machine data for tracking and compliance.

Factories use these platforms to automate workflows, trigger alerts, and maintain performance across the manufacturing floor, leading to better decisions and streamlined industrial processes.

Analytics and AI

Data analytics and machine learning turn raw IoT data into useful insights. These tools detect wear patterns, optimize performance, and recommend proactive steps like predictive maintenance. Teams use historical data and real-time inputs to increase overall equipment efficiency and reduce failures.

Predictive models also help refine business models, identify cost-saving opportunities, and unlock value hidden in the data. IoT solutions powered by AI support smarter planning and continuous process improvements.

Benefits of IoT Manufacturing

IoT in manufacturing improves visibility, speeds up response times, and turns IoT data into smarter actions. These systems help teams reduce waste, cut downtime, and increase operational efficiency. Here are the key benefits:

Improved Operational Efficiency

Real-time monitoring systems track every operation on the manufacturing floor, including shifts in load, speed, and system output. Operators receive alerts to fix issues before they impact throughput. IoT systems support real-time decisions and reduce process lags.

Increased machine utilization and faster changeovers cut idle time. These gains improve operational efficiency and lower costs for manufacturing companies, helping optimize the production process with less waste and more consistent output.

Predictive Maintenance

IoT-enabled devices detect vibration spikes, temperature changes, and other early warning signs in industrial equipment. Teams respond before failures disrupt production. Predictive maintenance reduces unexpected breakdowns and extends equipment lifespan.

Systems schedule service based on actual machine conditions, not fixed calendars. Maintenance costs drop, and asset performance improves. This approach helps manufacturers avoid unplanned downtime and keep the manufacturing process moving without interruptions or delays.

Enhanced Supply Chain Visibility

Connected devices and IoT technologies offer end-to-end visibility from raw material sourcing to final product delivery. Sensors track location, condition, and timing in real time. Teams use operational data for faster responses to disruptions, improving coordination.

Enhanced visibility supports supply chain optimization, on-time delivery, and reduced holding costs. In industries with complex logistics, these tools improve customer satisfaction and give the manufacturing industry stronger control over its distribution networks.

Energy Management

IoT-based energy systems monitor machine load, power spikes, and usage patterns across all zones. Smart factories use these tools to identify waste, reduce idle run times, and balance power demand. IoT solutions track consumption trends and suggest ways to cut energy costs.

By using edge computing and real-time alerts from IoT sensors, managers take corrective action before waste accumulates, improving efficiency and lowering utility bills across the production facility.

Worker Safety

IoT devices help monitor environmental hazards, machine proximity, and worker behavior in high-risk zones. Factories use gas, heat, and motion sensors to detect unsafe conditions. Industrial IoT systems instantly trigger alerts and shut down affected areas.

Location trackers boost visibility during emergencies. These safety tools enforce rules, reduce incident rates, and protect workers on the manufacturing floor, making smart manufacturing environments safer and more compliant with labor safety standards.

Challenges and Considerations

IoT in manufacturing offers great benefits but requires solid planning. Rolling out new tools takes effort, resources, and a strategy to handle tech, people, and change. The following are the potential challenges:

Cybersecurity Risks

Industrial companies face rising risks as more IoT platforms and internet-connected devices enter factory networks. Hackers often exploit weak points to access systems or disrupt operations. Teams must secure each access point, install firewalls, and run routine security checks.

Protecting the IoT ecosystem requires strong encryption, patch management, and user-level controls. A solid defense plan keeps production steady and guards IoT data from breaches that could harm both operations and customers.

Upfront Costs

Starting with IoT technologies demands upfront investment in embedded devices, software, sensors, and cloud systems. Hiring talent skilled in operational technology and data analytics increases setup costs. These early expenses often challenge small and mid-sized manufacturing companies.

Long-term benefits include fewer breakdowns, lower energy waste, and smoother processes. Many firms recover costs through improved uptime, better asset use, and gains tied directly to optimizing operations and data-driven decision-making.

Data Overload

Connected machines generate massive streams of sensor data and machine data around the clock. Without structure, teams lose time chasing false alarms or irrelevant trends. Using filters, tagging, and dashboards keeps the data collected focused and useful.

Well-organized inputs drive smarter alerts and better decisions. Relying on clean IoT data also prevents confusion in reporting and ensures efforts go into solving problems that matter most on the manufacturing floor.

Integration with Legacy Systems

Many factories still use machines built before the age of IoT devices. These systems lack built-in connectivity and often resist modern integration. Bridging gaps requires adapters, interface upgrades, or selective equipment replacement.

Teams assess which assets support data exchange and which need retrofitting. Integrating older manufacturing equipment with IoT systems takes planning but allows gradual adoption without disrupting core operations. Careful upgrades extend the life and value of existing machines.

Real-World Examples of IoT in Manufacturing

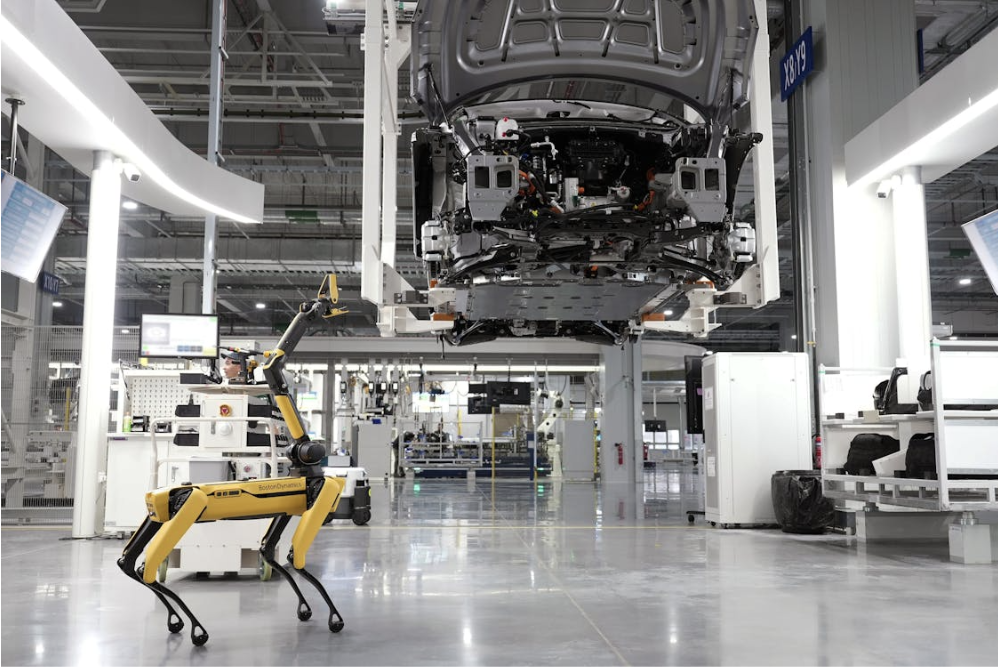

Automotive manufacturers use IoT sensors to automate quality control on the production line. Ford, for instance, relies on real-time monitoring to track torque and assembly data for each car.

Electronics firms like Siemens apply machine learning to detect defects and boost machine utilization. Their factories collect millions of data points from connected sensors to keep lines running at top performance.

Food and beverage companies apply remote monitoring for temperature-sensitive goods. Coca-Cola uses IoT-enabled devices to monitor sugar concentrations and batch conditions. These tools help ensure safe, consistent products.

Pharmaceutical manufacturers depend on accurate data from IoT devices to meet safety rules. Pfizer integrates IoT solutions in packaging and warehousing to track materials and reduce spoilage.

Each of these examples shows how different sectors use IoT in manufacturing to cut waste, improve efficiency, and stay competitive in high-pressure markets.

How IoT Manufacturing Supports Commercial Shipping and Logistics

IoT in manufacturing plays a direct role in improving logistics and delivery. Smart factories generate real-time insights that help teams plan better and respond faster across the supply chain.

IoT solutions help track goods from production to delivery. Remote monitoring tools follow shipment conditions and ensure temperature, timing, and security stay on point. Accurate tracking helps avoid delays and improves customer satisfaction.

Connected systems support inventory forecasting and warehouse automation. Operations use IoT data to align storage with demand and reduce overstock or stockouts. That makes the production process more reliable and predictable for both manufacturers and logistics providers.

Factories integrate edge computing and operational technology to sync with third-party shippers. That improves communication and visibility between warehouses, transport teams, and factory floors, making logistics more connected and efficient across the manufacturing industry.

Steps to Implement IoT in Your Manufacturing Operation

Starting with IoT in manufacturing takes focus and planning. Each step builds the foundation for faster decisions, better output, and smarter use of digital transformation tools.

- Assess Current Infrastructure: Review your existing systems and identify gaps where IoT solutions can reduce waste, improve visibility, or boost performance across your manufacturing process.

- Define Business Objectives: Set goals around efficiency, uptime, or predictive maintenance to guide investments and measure the return on IoT technologies in real-world factory settings.

- Choose the Right Technology Partners: Pick vendors who understand industrial processes and can deliver secure, scalable tools built for smart manufacturing and long-term revenue growth.

- Start with a Pilot Project: Use a single production line or asset group to test your plan. Capture early wins, track IoT data, and refine your deployment before scaling.

- Train Staff and Build Buy-In: Teach teams how to work with new tools. Focus on how IoT improves workflows, reduces manual tasks, and increases customer satisfaction.

- Monitor, Analyze, and Scale: Use dashboards to monitor data, test system performance, and expand to new areas of the plant based on results and lessons learned.

Start with one area, learn fast, and scale gradually to make IoT in manufacturing a success without overloading your team or systems.

Conclusion

IoT in manufacturing helps manufacturing companies improve the production process, reduce costs, and strengthen the supply chain. Tools like IoT systems, IIoT sensors, and IoT solutions support better quality control, faster decisions, and predictive maintenance across every part of the manufacturing process.

Teams using digital transformation tools build stronger business models, adapt to new demands, and stay competitive in a fast-moving market. Smart use of IIoT technology increases uptime and drives increasing productivity. Explore IoT options that align with your factory and logistics goals to move forward with confidence.