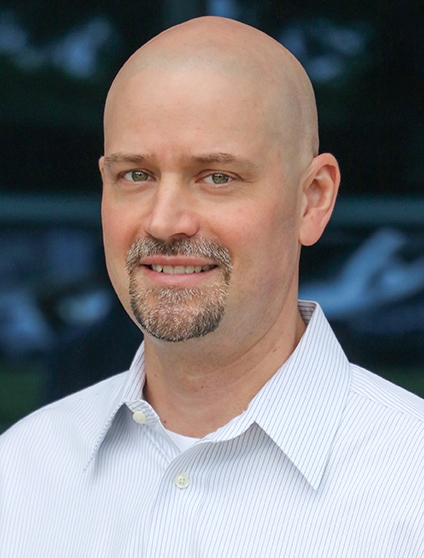

Reader Interview: Integrated Supply Network’s Theron Neese

Theron Neese is chief operating officer with Integrated Supply Network (ISN), a Lakeland, Florida-based distributor of automotive tools and equipment.

Theron Neese, COO, Integrated Supply Network (ISN)

Responsibilities: IT development and infrastructure, process improvement, distribution, procurement, quality, inventory control, and transportation.

Experience: Executive vice president, operations, FCX; vice president, replenishment and 3PL solutions, vice president, manufacturing and supply chain solutions, and multiple other executive positions with Cardinal Health.

Education: MBA, University of South Carolina; B.S., biology and chemistry, University of South Carolina Honors College.

Years ago, I worked as a warehouse operations supervisor. The plant manager conveyed that part of my job was to make it easier for tomorrow; to take one or two hours to fix a problem so I didn’t have to deal with it every day and so things would run more smoothly.

It’s a concept from Lean—to always be looking for the next bottleneck and working to tackle it. It stuck with me and has been part of my Lean journey.

At ISN, I’m in charge of procuring domestic national brands and company private brands from overseas, planning inbound and outbound transportation, and overseeing pick, pack, and ship.

One thing that makes all these responsibilities challenging is that we truly are omnichannel—we operate in ecommerce, business-to-consumer, and business-to-business. And we partner with regional and national wholesalers and distributors.

We also do a lot of same- and next-day shipping. We take orders until 3 p.m. and then ship them out on the same day. All this adds complexity.

In my five years at ISN, I’ve focused on distribution and driving improvement across the enterprise. Over the past few years, we’ve consolidated 18 distribution centers to seven, many as a result of acquisition activity.

Handling change requires several steps. One is making sure we have the right people. While you can teach most things about business, I look for drive, ownership, and process orientation. I want to hire people who drive forward and need to be held back versus prodded on. If a team member takes ownership, they will work to improve the company, not just their area. And a process orientation ensures that people are always looking to improve.

I’m also extremely data-driven, whether the issue is inventory, financial, or something else, so we don’t make emotional decisions. For instance, when judging carriers, we look at their current performance and whether they’re meeting our needs.

We also consider simplicity—it doesn’t make sense to use 50 carriers at one site.

I try to be transparent and use Lean processes: plan, do, check, act. We constantly look at our processes to make sure we do better next time.

As a distributor, we are hit hard by inflation as we try to pass on manufacturer increases while remaining cost competitive. We’ve looked for ways to reduce costs, while maintaining inventory availability and service. Those have been key challenges.

We implemented Locus Robotics for warehouse efficiency and Blue Ridge for supply planning. Pick rates have more than doubled, and our inventory has been reduced by more than 30%. Every day, I use Power BI to review inventory levels and transactions and I engage in a lot of communication around supply levels, to make sure we utilize our capital effectively.

We’re also implementing a more robust sales and operations planning solution. We involved sales and category management in the process, so we reduce inventory in the right places, and our changes are tied to customer demand.

In college, I was a chemistry and biology/pre-med major. I took a break from school after earning my Bachelor’s degrees and worked in different roles for a liquid pharmaceutical manufacturer.

I really enjoy operations because of the ability to rapidly improve the business and solve problems. Plus, every day presents a new challenge.

Theron Neese Answers the Big Questions

Theron Neese is chief operating officer with Integrated Supply Network (ISN), a Lakeland, Florida-based distributor of automotive tools and equipment.

1. If you were granted one superpower, what would you choose?

The ability to read minds. (I’d also need the ability to turn this power on and off.)

2. What would you tell your 18-year-old self?

To slow down and enjoy the ride. I’d also tell him to take on different roles. While I did a brief stint as vice president of sales, I wish I had taken on more roles at the manager or director level. You learn a lot about the business when you’re in the weeds.

3. If you could travel anywhere in the world, and time and money weren’t constraints, where would you go?

The place I’ve enjoyed the most is Alaska in the summer. I’d also like to see the pyramids and the Great Wall of China. I think of supply chain and manufacturing developments and how in ancient times, they were able to create these structures without today’s tools. They are marvels of human ingenuity.