Prepping for Peak-Season; Next-Level Yard and Dock Ops; Strategies to Mitigate Disruption; & More Supply Chain News

Get the latest supply chain and logistics insights from expert research, analysis, and trend reports.

Avoiding Peak-Season Pain

As retailers prepare for the 2025 peak season, a recent post-season fulfillment analysis from Deposco serves up a sobering reality check: Expectations are outpacing execution. According to Deposco’s report, 93% of supply chain leaders felt confident heading into the 2024 holiday rush—but when the dust settled, only 58% reported success in meeting customer expectations for delivery timing and order accuracy.

That’s a 28-point gap between anticipated and actual performance—something retailers do not wish to repeat. Data from the report helps explain what’s behind this disparity:

- Technology shortfalls: While 70% of executives believed their fulfillment systems were up to the task, just 42% report that those systems actually delivered.

- Labor pains: Despite 51% planning to offset workforce demands with automation and seasonal hires, 65% still faced major staffing challenges.

- Misaligned systems: The study exposed a widespread overestimation of system capabilities across order and warehouse management.

The report also outlines three key investment areas for peak-season readiness:

1. Unified supply chain platforms that integrate warehouse and order management systems

2. Artificial intelligence-powered workforce optimization tools to mitigate labor volatility

3. Customer experience enhancements that build brand loyalty even during fulfillment crunches

Ann Drake Builds Leadership Legacy

Former supply chain luminary Ann Drake has a new mission: empowering the next generation of women leaders to shape the future. And she will soon have a new place to further that goal—a forthcoming Women’s Leadership Center being built in Williams Bay, Wisconsin. The 24,000-square-foot retreat, situated above Geneva Lake, is set to become a nexus for women leaders to engage in innovation, collaboration, and leadership development.

The center is a partnership between Lincoln Road Enterprises, an organization Drake founded to elevate women’s leadership, and Studio Gang, an international architecture and urban design firm led by Jeanne Gang.

Drake—who had a trailblazing career as CEO of DSC Logistics before founding Lincoln Road and AWESOME (Achieving Women’s Excellence in Supply Chain Operations, Management, and Education), a community of more than 1,500 women in senior supply chain roles, views the new center as “a place where conversations happen that will change the world.”

The new center features gently curved spaces and expansive windows (see rendering above). Situated on 8.6 acres, it will comprise three main structures—the Lodge for large gatherings and dining, the Council for meetings and conferences, and the Cabin for intimate retreats. The Center broke ground in July 2024 and is expected to open in 2026.

Dock and Yard Ops Level Up

Often overlooked as merely an extension of transportation and warehousing, dock and yard operations are critical components of supply chain efficiency—and the sector is currently undergoing significant transformation. Companies that focus on these elements as distinct functions from their transportation and warehouse networks can gain a leg up in competition, finds the 2025 State of Yard and Dock Management Report from C3 Solutions.

Many supply chain organizations still rely on manual processes for managing dock and yard operations, the report indicates. But as their importance gains favor, companies now seek real-time visibility for these areas.

Here are some top findings on the state of the dock and yard management sector:

- Manual inefficiencies remain a top challenge: 39.1% of respondents identify manual processes as a significant barrier to efficiency.

- Yard congestion disrupts operations: 36.3% of businesses struggle with congestion, leading to bottlenecks and delays.

- Labor shortages persist: 35% report difficulties in maintaining adequate staffing levels, exacerbated by rising labor costs.

- Lack of real-time visibility: 31% of respondents state that the absence of real-time data slows reaction time and exception management.

- Limited automation increases costs: 27.5% indicate that their yards rely heavily on manual processes, leading to higher operational expenses.

- Late carrier arrivals require flexible response: 60% reschedule appointments and notify stakeholders, while 48.5% build buffer times into schedules.

3 Strategies for Managing Disruptions

Chief supply chain officers (CSCOs) have plenty of things keeping them up at night right now as supply chains face major simultaneous disruptions. Instead of counting sheep, Ken Chadwick, vice president, advisory, in Gartner’s Supply Chain practice, offers three high-impact strategic actions that CSCOs can implement to help prepare for a period of prolonged uncertainty. Shared at the recent Gartner Supply Chain Symposium/Xpo in Orlando, this trifecta, according to Chadwick, can help leaders prioritize in order to deliver value.

They are:

1. Navigate risk and uncertainty by investing aggressively in advanced visibility and building an iterative scenario-planning capability. Chadwick emphasizes that while CSCOs recognize the value of advanced visibility and scenario planning, many fall short of fully executing these capabilities due to obstacles such as data challenges and incomplete tech stacks.

2. Orchestrate dynamic supply chain outcomes through diversifying networks and taking ownership of commercial outcomes. Scenario planning enables CSCOs to drive growth through flexible network design and analytics-driven insights, while also taking ownership of commercial outcomes beyond short-term cost and portfolio concerns.

3. Accelerate innovation by matching ambitions with capabilities, while enabling and inspiring teams to lead the transition. To accelerate innovation and extract value from technologies like AI, Chadwick advises aligning investments with an organization’s risk profile and culture, making both tactical and transformative bets, and supporting adoption through dedicated change leadership.

Temp Check: Tariffs

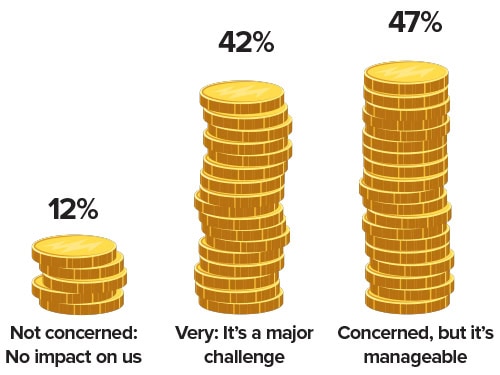

How concerned are you about

the impact of tariffs on your

supply chain costs and long-

term business success?

In a recent LinkedIn poll conducted by Inbound Logistics, nearly 90% of respondents express concern about the impact of tariffs on supply chain costs and long-term business success. While 42% call tariffs a “major challenge,” the largest group—47%—say the issue is “manageable.” Only 12% report no impact at all, signaling that tariffs remain a key pressure point for most logistics and supply chain professionals.

Working 9:00 TO 6:10

Does it seem like you’re working longer hours than most people you know? You may be right. The logistics sector has earned the dubious distinction of having the longest workday at 9 hours and 10 minutes—26 minutes longer than the cross-industry average, according to ActivTrak Productivity Lab, which based its findings on three years of workplace data spanning 23 industries, including 774 companies and 218,900 employees.

In addition, the research shows logistics leads all industries with 20% of workers overutilized and 15% at risk of burnout. ActivTrak defines “overutilization” as an employee who exceeds their daily productive hours goal by more than 30%, based on thresholds set by their employer. Burnout risk applies to employees who spend more than 75% of their time overutilized annually.

The news isn’t all bad, however. It turns out logistics workers are also highly productive and collaborative. Additional findings include:

- Logistics workers log the most daily productive time at 7 hrs, 3 minutes—46 minutes longer than the overall average.

- Logistics workers rank second in daily collaboration time at 56 minutes—18 minutes longer than the overall average.

- 72% of logistics workers adopted AI tools in 2024, the most across industries studied.

- Logistics employees have the highest daily AI usage, nearly three minutes longer than the overall average.

Manufacturers Top Cyber Attack hit List

The manufacturing sector has become the foremost target for cyber adversaries, surpassing more than 20 other industries in alerts generated, confirmed threats detected, and incident response engagements, according to Arctic Wolf’s 2025 Threat Report. The report also shows a rise in ransomware attacks and indicates that 96% of ransomware attacks involve data theft, indicating that double extortion, where attackers steal and threaten to leak data before encrypting systems, is now the norm.