Warehouse Solutions Hit the Mark

These warehouse innovations rack up efficiency gains and process improvements, bringing competitive advantages to supply chain operations, big and small.

↑ Automated Compact Truck (ACT) Series: The ACT line from Logisnext Solutions can fit in existing warehouse environments without rack modifications and operate between the warehouse and loading docks. The automated guided vehicles work with manual forklifts. The ACT series can navigate narrow aisles and features a touchscreen and LED fins that show its current state from a distance for improved safety and communication with warehouse personnel.

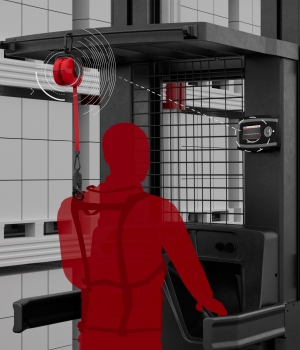

← Raymond Integrated Tether System: The new tether solution from Raymond is an operator assist tool designed to alert workers and managers and to limit lift truck functionality if an operator is not properly tethered. The wireless connection in the system is compatible with Raymond lift trucks and offers data-gathering capabilities that can help reinforce best practices with operators.

← Raymond Integrated Tether System: The new tether solution from Raymond is an operator assist tool designed to alert workers and managers and to limit lift truck functionality if an operator is not properly tethered. The wireless connection in the system is compatible with Raymond lift trucks and offers data-gathering capabilities that can help reinforce best practices with operators.

→ Ergodyne Thermal Solutions: Ergodyne introduced four new thermal solutions, designed for work crews in refrigerated facilities. The N-Ferno 6475 insulated freezer coveralls, 6476 insulated freezer jacket, and 6477 insulated freezer bib overalls are rated to -50°F for up to five hours of moderate activity. The ProFlex 850 insulated freezer gloves are rated to -20°F for up to one hour of moderate activity.

→ Ergodyne Thermal Solutions: Ergodyne introduced four new thermal solutions, designed for work crews in refrigerated facilities. The N-Ferno 6475 insulated freezer coveralls, 6476 insulated freezer jacket, and 6477 insulated freezer bib overalls are rated to -50°F for up to five hours of moderate activity. The ProFlex 850 insulated freezer gloves are rated to -20°F for up to one hour of moderate activity.

↓ Combilift CB15-5E: Equipped with ergonomic features, the counterbalance truck has multidirectional ability and can handle long and bulky loads. A recent addition to Combilift’s line of electric models, the truck offers 15,500 pounds of lift capacity, long battery life, and an auto swivel seat for driver comfort.

← ResGreen LilBuddy: The autonomous mobile robot (AMR) can move loads up to 220 pounds without tape, reflectors, or tags. Utilizing natural feature guidance or magnetic tape hybrid guidance, it can tow loads and drop them off automatically at a given location. With a 17-inch by 17-inch base, LilBuddy is one of the smallest AMRs in the industry. It can turn in place, making it ideal for narrow areas.

← ResGreen LilBuddy: The autonomous mobile robot (AMR) can move loads up to 220 pounds without tape, reflectors, or tags. Utilizing natural feature guidance or magnetic tape hybrid guidance, it can tow loads and drop them off automatically at a given location. With a 17-inch by 17-inch base, LilBuddy is one of the smallest AMRs in the industry. It can turn in place, making it ideal for narrow areas.

• HaiPick A42T Telescopic Lift ACR: The A42T autonomous case-handling robot (ACR) from Hai Robotics can pick and store plastic totes and carton boxes at a height of up to 32.8 feet. The A42T has multiple storage trays to carry up to nine payloads simultaneously.

↓ Yale Narrow Aisle Reach Truck: The Yale reach truck is designed to maximize productivity in high-density configurations. The truck offers 3,000-to-4,500-pound load capacities and single or double-deep reach capabilities to take advantage of positions in storage racking two pallets deep, helping maximize storage density. Ergonomic features include an optional suspended floor that reduces shocks and vibrations transmitted to the operator by up to 60%.

↓ AutoStore Storage & Retrieval System: The AutoStore system from Dematic is a compact, scalable robotic storage and piece picking solution. The ultra high-density storage and buffering system supports goods-to-person piece picking. The AutoStore solution brings products directly to the operator, streamlining the picking process by reducing warehouse foot traffic and keeping products close to where they are required to be.

← BionicHIVE SqUID: The SqUID solution from BionicHIVE eliminates the need to manually pick or walk between aisles. The autonomous robotic solution can sort, pick, and replenish cartons directly to/from any spot in the existing warehouse racking. The robots can travel on the ground alongside humans and other equipment and, when rails are installed, they can also move vertically on any rack, placing and retrieving boxes and delivering them anywhere in the facility.

← BionicHIVE SqUID: The SqUID solution from BionicHIVE eliminates the need to manually pick or walk between aisles. The autonomous robotic solution can sort, pick, and replenish cartons directly to/from any spot in the existing warehouse racking. The robots can travel on the ground alongside humans and other equipment and, when rails are installed, they can also move vertically on any rack, placing and retrieving boxes and delivering them anywhere in the facility.

↓ SnapControl: Synergy Logistics’ multi-agent orchestration platform, SnapControl, helps warehouses get the most out of automation devices and robots in their distribution centers. The software recently helped a U.S. e-retailer optimize the allocation of tasks between human and automated resources and achieve a sixfold increase in productivity.

↓ Destuff-it™ Portable Ergonomic Conveyor: The portable conveyor from Gorbel can provide a safe and efficient method for handling floor-stacked products. The Destuff-it features an adjustable hydraulic platform and battery-powered drive system. Workers can position the machine against a product wall and slide each product onto a conveyor without bending or reaching. The Destuff-it can also reduce the number of doors needed for the unload operation with more trailer turns per door.

← The Hyster® A Series: The line of forklifts offers configurability to match operational requirements—supporting scalable operations and offering a low total cost of operation. The Hyster Dynamic Stability system comes standard on each truck, improving stability and lowering the likelihood of forward and sideways tip overs.

← The Hyster® A Series: The line of forklifts offers configurability to match operational requirements—supporting scalable operations and offering a low total cost of operation. The Hyster Dynamic Stability system comes standard on each truck, improving stability and lowering the likelihood of forward and sideways tip overs.

→ StorFast Automated Storage and Retrieval System (AS/RS): Signode’s cart-based system can manage the location of every pallet in a facility, determining which pallets to retrieve based on inventory rules and replenishing high-volume locations. The solution integrates with existing warehouse management systems and works within the building footprint to optimize storage space.

→ StorFast Automated Storage and Retrieval System (AS/RS): Signode’s cart-based system can manage the location of every pallet in a facility, determining which pallets to retrieve based on inventory rules and replenishing high-volume locations. The solution integrates with existing warehouse management systems and works within the building footprint to optimize storage space.

↓ Interroll LCP AMR Top Module: The new solution from Interroll combines its light conveyor platform (LCP) with an autonomous mobile robot. The top module enables the handling of lightweight goods on the AMR. It allows the LCP to integrate with other robotic solutions to support scalable materials handling operations.

No Flip-Flopping on Supply Chain Efficiency

Alpargatas—owner of Rothy’s and the Havaianas sandals brand—turned to Mecalux storage solutions for help fulfilling and distributing 1,500 orders per day at two logistics facilities in Brazil: Campina Grande and Santa Rita.

Alpargatas—owner of Rothy’s and the Havaianas sandals brand—turned to Mecalux storage solutions for help fulfilling and distributing 1,500 orders per day at two logistics facilities in Brazil: Campina Grande and Santa Rita.

The Campina Grande distribution center consolidates stock from the company’s manufacturing centers in northeastern Brazil. Merchandise is stored on conventional racks with capacity for 34,000 pallets. This DC features 40 loading docks and a staging area to handle the fulfillment and shipment of 1,500 orders per day, including Havaianas flip flops. The footwear is distributed in the country and internationally.

The Campina Grande distribution center consolidates stock from the company’s manufacturing centers in northeastern Brazil. Merchandise is stored on conventional racks with capacity for 34,000 pallets. This DC features 40 loading docks and a staging area to handle the fulfillment and shipment of 1,500 orders per day, including Havaianas flip flops. The footwear is distributed in the country and internationally.

For the Santa Rita plant, Alpargatas chose Mecalux’s semi-automated pallet shuttle to perform pallet storage and retrieval operations. The high-density system houses more than 1,000 pallets in less than 3,230 square feet. The compact solution consists of a shuttle car with an electric motor that transports pallets inside the racking autonomously.

Warehouse Tech Helps With Young Recruits

One-third of warehouses are more than 50 years old, with 70% constructed before the 21st century, finds a report from real estate services firm Newmark. While innovation is necessary for operations, it is also vital for recruitment—especially the next generation of warehouse workers.

The new generation of warehouse workers wants to work in a digital warehouse alongside robots, leverage AI for efficiency, and automate mundane tasks. Given the majority of millennials’ and Gen Z’s lives have been centered around technology, these solutions are attractive because they offer flexibility, independence, and career advancement.

–Brandon Black, SVP and General Manager, Ivanti Wavelink