13 Top Benefits of Automating Your Supply Chain

From attracting talent to boosting visibility, here are the advantages you gain from automating some or all of your supply chain.

Many organizations are implementing or considering investments in automation solutions. The goal for most? To drive workforce productivity and agility, which was cited by 60% of respondents to a recent IBM survey.

“For too long, we’ve thought about supply chains as cost centers,” says Rob Cushman, senior partner, supply chain transformation, with IBM Consulting. At their best, however, supply chains are growth drivers, he adds.

Automation is key to corporate initiatives to drive growth. As more supply chains digitize, they can deliver a wealth of data. A lack of automation, however, can keep supply chain leaders from accessing real-time, enterprise-wide information that can help them identify operational inefficiencies.

Here’s a look at the benefits possible from automating the supply chain.

Enhance Inventory Visibility

Many benefits possible with automation stem from the visibility it can provide.

Visibility and automation are key tools for companies facing pressure from customers, as well as internally, to cut inventory and costs.

“CFOs are closely monitoring supply chain and logistics operations,” says Ashutosh Dekhne, partner and head of Americas supply chain operations and tech practice with EY. “Many are questioning the labor required to make and ship items.” Automation can streamline processes, allow workers to contribute strategically, and cut costs.

The inventory visibility made possible through automation helps companies avoid overstocking products that are at risk of growing obsolete, or understocking hot-selling items and losing sales.

Accelerate Speed to Market

Companies can leverage automation to rev up speed to market. When they leverage dynamic planning solutions and employ automation, companies can act as soon as they receive market signals.

“Conversely, if a company takes several days to plan, it negates the benefit of getting the demand signal quickly,” Dekhne says.

Attract Workers

By making many warehouse and distribution center positions more appealing, automation can help companies tackle the current labor shortage. “Nobody wants to work in a facility where the easiest thing to use is their cell phone and everything else is 15 years behind the curve,” Dekhne says.

Meet Sustainability Goals

Even once products are in transit, automation has a role to play. Vehicle routing and scheduling solutions enhance full truck utilization and optimize routes, reducing emissions, among other benefits, says Robert Recknagel, vice president, logistics and manufacturing with Flexis, a provider of supply chain solutions. Integrating a three-dimensional container-loading solution further maximizes space utilization and cuts transportation costs.

These benefits have gained prominence as attention to sustainability increases. “More companies are aiming to streamline processes and align automation efforts with initiatives that address environmental concerns,” notes Craig Moore, vice president, sales, North America, with Körber Supply Chain.

Gain Control

Manual inventory management methods are no longer productive. Many companies are incorporating Inventory visibility technology into their omnichannel fulfillment operations to better predict inventory flows and reduce operating costs.

Once an organization has data, it needs to convert it to information. This may take the form of a supply chain control tower, which Gartner defines as “a combination of people, process, data, organization, and technology that captures and uses (close to) real-time operational data from across the business ecosystem to provide enhanced visibility and improve decision making.”

By assembling information from across a supply chain, control towers can develop “one source of truth,” says Barry Bradley, head of supply chain with Crisp, a collaborative commerce solutions provider.

When all areas of an organization work from the same information, they can make better-informed decisions, he adds.

Take the example of RxSugar, which provides allulose, a plant-based alternative to regular sugar, through more than 15,000 stores and 30-plus brick-and-mortar and ecommerce channels.

“As a relatively new product, our main challenge has been the supply chain-constrained ecosystem in which we operate,” says Steve Hanley, founder and chief executive officer.

The limited universe of allulose manufacturers, combined with RxSugar’s impressive growth, calls for a carefully planned and streamlined supply chain. To help reach this goal, RxSugar implemented a data platform from Crisp that can aggregate data on sales, distribution, inventory, and other functions from across the company’s distribution channels.

Hanley and his team can assess top-level demand across the network in real time, plan production, and keep shelves stocked. “We are now able to get ahead of our supply chain and we can order materials and packaging with 12-week lead times,” he says.

Leverage Robotics

Robots, such as Boston Dynamics’ Stretch, can boost warehouse efficiency and improve picking accuracy, among other benefits.

By 2027, more than 75% of all companies will have adopted some form of cyber-physical automation within their warehouse operations, according to Dwight Klappich, vice president and fellow with Gartner’s supply chain practice, in a recent brief.

Mobile robots typically require lower capital investments than fixed automation systems, says Rowan Stott, research analyst with Interact Analysis. In addition, it’s typically easier to add robotics to existing warehouses than to put in a new, fixed system.

Adding to robotics’ appeal is their dropping prices. Between 2011 and 2022, the average price of an industrial robot fell by about half, finds EY research. Conversely, wages and salaries rose about 43% over the same period, according to Statista.

Boost Decision-Making

Like control towers, digital twins can aid in decision-making. These are virtual representations of objects or systems that span their lifecycle, are updated with real-time data, and use simulation, machine learning, and reasoning to help decision-making, IBM explains.

Companies can use digital twins to simulate the impact of an event, such as a supplier that halts plant operations due to a weather event. To provide the most value, a digital twin should concentrate on modeling hot spots and critical components. “Be smart about what you want to model,” Dekhne recommends.

Improve Data Insights

In the supply chain world, artificial intelligence (AI) is capturing attention. Successfully implementing AI-enabled supply chain management solutions enabled early adopters to improve logistics costs by 15% and inventory levels by 35%, among other benefits, compared to their slower-moving competitors, McKinsey research found.

Generative AI is upping the ante. Generative AI empowers users to build their own interactive models, Deknhe says. For instance, a supply chain planner trying to determine the impact of a 20% jump in demand for a product has typically needed to manually assess supply levels and contact suppliers to get information on raw material supplies, among other data—a process that can take days. Generative AI can ask the same questions, work with the data, and adjust models to more quickly provide this insight.

Advance with Software

While traditional software solutions, like warehouse management systems, may not generate the same buzz as AI, they remain critical to many supply chains. They also continue to advance. Thirty years ago, companies could complete materials requirement planning (MRP) about once a week.

“We would dim the lights whenever we hit the enter key,” recalls Steven Benz, senior consulting manager with Panorama Consulting. Today, companies can generate MRP reports every 15 minutes.

Current algorithms can automate forecasting, inventory control, and supplier selection, among other functions. While algorithms—sets of finite rules or instructions to be followed in calculations or other problem-solving operations—aren’t true AI, they make software solutions more robust and useful.

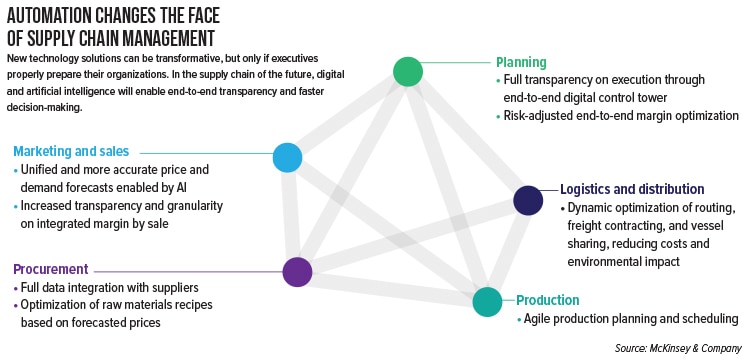

Automate from End to End

More companies are evaluating and automating supply chains in their entirety, rather than focusing on optimizing individual pieces. A more comprehensive approach can help supply chains better handle disruptions, such as geopolitical events.

“End-to-end process automation can bring together siloed systems, connect people involved in different processes, and allow information to flow securely, says Gary Cassell, global industry lead, manufacturing and automotive, with Appian.

Organizations can act on the information to build resilience and optimize performance. When companies link their systems through a digital layer, they minimize the need to rip out solutions that are working but disconnected.

End-to-end solutions often encompass multiple systems. For instance, supply chain execution systems can expedite operations for swift, efficient task completion, while warehouse control systems (WCS) can serve as vendor-neutral hubs, orchestrating diverse material handling technologies for uninterrupted material flow. A WCS can integrate with a warehouse management system to optimize material flow.

The result? “An integrated process, enhancing warehouse throughput and performance,” Moore says.

Connect Through the Cloud and APIs

Automation has generally lagged where old systems need to be linked with new software solutions. Cloud-based software solutions can help by enabling the rapid exchange of data between all supply chain parties in real time, so data-based decisions can quickly be made.

APIs also offer a scalable solution for sharing data, unlike the generally cumbersome practice of emailing spreadsheets back and forth. APIs encompass a set of defined rules that allow different applications to communicate with each other. They enable access to information by sharing folders via the cloud.

Optimize Routes

Route optimization technology can improve delivery productivity while hitting customer service targets. This improvement can reduce delivery costs—distance, vehicles, or drivers—and increase delivery capacity.

It’s not only the operations inside warehouses or distribution centers where automation can drive efficiency. Route optimization software can leverage AI to dynamically match carrier capacity with loads, minimizing empty miles and helping carriers fill their trailers, says Justin Haines, director, fleet solutions with Coyote Logistics, which offers such a solution.

Improve Yard Management

In contrast to the automation seen in many warehouses and in transportation management, the “yard often is clipboards and walkie-talkies,” says Greg Braun, chief revenue officer with C3 Solutions, which offers yard management solutions. Yet technology has a role to play here.

Yard management automation can include a range of solutions. Some systems allow drivers to check in with their smart phones. Artificial intelligence can support task optimization, such as determining optimal trailer moves, Braun says.

As technology advances, the value of automating the supply chain will only grow. Companies that are quicker to leverage automation will gain first mover advantages, as well as the ability to attract top-notch talent. “It’s a win-win,” Dekhne says. n

7 Steps to Implementing Automation

While the benefits of supply chain automation are clear, the skill with which it’s implemented contributes to a solution’s success. These guidelines can help.

1. Focus on adding value. The solutions that will add value vary by company, says Lisa Anderson, president with LMA Consulting Group. Ecommerce retailers may find that automating the order-taking process adds the greatest value, while distributors might look to advanced analytics and planning solutions to better manage inventory and free up cash.

2. Take it step by step. Start with a solution that brings a rapid return on investment and addresses the most urgent problems, and then build from there. Introducing too many functions at once increases complexity and can overwhelm employees.

3. Invest in change management. When new solutions fail to live up to expectations, it’s rarely the technology that’s the reason, says Sandy Gosling, partner with McKinsey. Instead, it’s often a failure to build the capabilities needed to leverage the technology. Supply chain leaders can help employees understand how a new way of operating will benefit them and the company, and then train them on the systems.

4. Know your starting point. This isn’t always obvious, given corporate restructurings and changes in IT solutions. If you can’t identify the starting point, you risk generating needless disruptions when automating.

5. Check the data. The GIGO (garbage in/out) rule applies. While perfection isn’t necessary, data should be “directionally correct,” Anderson says.

6. Consider the impact to the organizational structure. It likely will change as new data becomes available. Employees who were good at finding problems may find their roles supplanted by technology. Instead, they’ll be charged with deciding how to address the problems.

7. Develop back-up plans. Automation can fail even with the best of care. Backup plans and systems can help with recovery until systems can be restored.

Pouncing on Automation

Automation is helping Tiger Tail USA “keep our team lean and efficient,” says Spring Faussett, president of the muscle recovery tools producer. Oracle/Netsuite’s manufacturing, inventory, and accounting system enables Tiger Tail to more systematically manage orders.

Automation is helping Tiger Tail USA “keep our team lean and efficient,” says Spring Faussett, president of the muscle recovery tools producer. Oracle/Netsuite’s manufacturing, inventory, and accounting system enables Tiger Tail to more systematically manage orders.

Among other benefits, Tiger Tail can enter product and vendor information, and then use reports and alerts to ensure proper ordering lead time and quantity forecasting.

When Tiger Tail receives inventory, it can quickly add this information and make it visible to all users. The company also uses inventory reports to work with vendors and shipping companies to ensure full truckloads.

“Although the system is expensive for our small company, it saves at least one employee and lowers accounting costs over the course of a year,” Faussett says.

On Tiger Tail’s consumer websites, custom APIs push orders into Netsuite, minimizing human handling. Custom APIs allow Tiger Tail to easily add new websites and products, which otherwise would be difficult to manage, Faussett adds.