3PLs Discover Value for Shippers

Technology, service and communication will differentiate third-party logistics providers.

For more than two decades, Uncommon Goods has partnered with artisans and craftspeople to offer unique gifts and home decor—like vases shaped in Xs and Os, personalized kids’ books, and travel cubes crafted from recycled saris. This business model creates supply chain challenges.

Many of the company’s 7,000 stockkeeping units (SKUs) are fragile and produced in small batches. Inventory can vary greatly from one season to the next. Many artisans, like other small business owners, have less-than-standardized shipping functions.

“It is challenging to support working with these artists,” says Robert Carucci, head of operations. In addition, Uncommon Goods’ order volume can swing dramatically during the year.

To tackle these challenges, Uncommon Goods turned to ITS Logistics, a third-party logistics (3PL) provider that offers national omnichannel distribution and fulfillment services. ITS helped to revamp Uncommon Goods’ fulfillment and distribution operations.

Facing Challenges

Many retailers, manufacturers, and other shippers have confronted several years of supply chain challenges. Among them: between May 2020 and May 2022, long distance truckload rates jumped about 64%, according to the St. Louis Federal Reserve. Shipment transit times between China and the United States jumped from about 40 days pre-pandemic, to about 70 days in July, August, and September 2021, the World Economic Forum reports.

Now, many shippers are attempting to make sharp turns and shift from fire fighting for capacity to developing the foresight that can inform their strategy over the next few years, says Rupal Deshmukh, principal in Kearney’s strategic operations practice.

At the same time, shippers are monitoring potential challenges, such as inflation and possible recessionary conditions.

Logistics providers’ ability to help shippers address these challenges is one factor driving growth in the global logistics market, which is expected to increase by nearly 7% annually between 2022 and 2030, FTI Consulting predicts.

Also boosting the logistics market is growth in e-commerce logistics, shortages of containers and drivers, port closures and congestion, and restricted airfreight capacity, FTI says.

But even as it grows, the third-party logistics provider market faces challenges. “The market is soft, with a lot of competition vying for the same freight and customers,” says Ben Benfield, director of customer operations with EASE Logistics, a supply chain and transportation solutions provider.

Many logistics providers operate on low margins and can find it difficult to add talent and technology to create extra value.

That’s particularly true for smaller firms, who must spread any investments across fewer clients. Many struggle with low levels of digitalization, fragmented and disconnected systems, and a lack of data sharing across the shipping chain.

However, “the success of the largest players shows a great return on investment in technology,” says Inna Kuznetsova, chief executive officer with ToolsGroup, a global supply chain planning and optimization firm.

To differentiate themselves, logistics providers need to leverage technology to assist with supply chain planning, inventory optimization, and providing flexibility in tracking and rerouting.

“It requires the logistics providers to have a good grip on their own data, integrate with customer systems, and be more than just the travel agents for the goods by becoming true partners in shipping,” Kuznetsova says.

Technology That Fits

The technology implemented by logistics providers should fit and enhance shipper operations, says Steve Simonson, vice president, Tompkins Solutions, a subsidiary of global supply chain services firm Tompkins International.

This can include integration with the shipper’s order management system (OMS), real-time information dashboards, and warehouse management system (WMS) functionality that directs activity on the warehouse floor.

Even as technology becomes more important, service remains key. “The logistics companies who provide great service and communication will remain leaders in the industry,” Benfield says.

The following logistics providers are demonstrating that they’re among this group.

Getting Creative: Uncommon Goods & ITS Logistics

While Uncommon Goods appeals to customers looking for creative products, it also competes with other retailers and needs to offer similarly rapid, efficient shipments, including during the holiday season. This requires supply chain solutions that can efficiently scale to adjust to drastic seasonality swings. ITS’s solution works effectively with Uncommon Goods’ diversity of products and shippers.

Before partnering with ITS, Uncommon Goods shipped all products from a distribution center in Brooklyn, New York. However, with vendors on both the west and east coasts, Uncommon Goods needed a supply chain partner that could reduce shipment time and costs.

Through its partnership with ITS, Uncommon Goods now also has distribution solution in Reno, Nevada. A percentage of SKUs are replicated in its West Coast operation, and about 25% of its customers are on the West Coast.

Based on the inventory, transportation zones, and carriers, Carucci and his team decide from which warehouse they’ll fill each order. Shipping information and inventory availability travels between the warehouses using API connections.

In Reno, ITS Logistics consolidates inbound shipments from vendors, fulfills orders, and handles returns. The West Coast operation cut the time required to move products to customers, so about 90% of Uncommon Goods’ customers across the country can enjoy same-day shipping. In addition, customers can receive immediate notifications of transit information.

The East and West Coast operations are similar in terms of how they pick and pack, so there’s consistency. Standardization also means customers enjoy the same fulfillment experience, whether their orders are filled in Reno or Brooklyn. “That’s especially important for a gift retailer,” Carucci says.

ITS also flags the SKUs that are moving most quickly. It then adjusts their slotting locations in the warehouse so they can be picked more efficiently.

As a gift retailer, Uncommon Goods’ order volume can increase dramatically during the holidays. In addition to more orders, the orders themselves often are larger.

Both technology solutions and workers need to adjust, not just to higher volumes, but also to what the orders look like. “The processes are dramatically different,” says Kasia Wenker, director of supply chain solutions with ITS Logistics.

To ensure an effective partnership, Carucci and his team regularly communicate sales forecasts and updates with their colleagues at ITS. “We get very granular,” he says.

They relay information on, for instance, the percentage of shipments that will be fragile, so ITS can have the right supplies and staff ready to go. E-commerce retailers have more challenges in forecasting sales compared to business-to-business companies, so constant communication is essential.

Other critical components of the partnership are ITS’s flexibility and understanding of the fluctuations in sales volume, and its interest in working together. “We build out our processes together,” Carucci says.

Uncommon Goods has also benefited from the expertise ITS can offer. ITS recommends ways to improve operations, including packaging, warehouse planning, and regional carrier selection.

For instance, ITS helped Uncommon Goods adjust its box sizes so they are appropriately sized for the item being shipped, while also preventing damage to shipments in transit.

Through its partnership with ITS, Uncommon Goods has also begun working with recycled mailers. “We’re a B Corporation, so sustainability is important,” Carucci says. “ITS’s expertise and constant insight to trends in the industry is very helpful.”

Single Source: Fibox Enclosures USA & Nexterus

From its headquarters in Finland, Fibox Group has grown to a leader in thermoplastic enclosures that safeguard electrical and electronic components in hostile and hazardous environments. Its products can be found in infrastructure and utility applications, electronic manufacturing, and industrial plants, among other uses.

Ken Hynes, director of purchasing and logistics with Fibox Enclosures USA, connected with Nexterus, a full-service supply chain management and technology company, to gain a single source for logistics management services across North America.

“Nexterus has all the capabilities to address import ocean freight, customs clearance, less-than-truckload, truckload, and parcel,” Hynes says “Using Nexterus as a true partner and extension of the Fibox team has helped streamline our transportation and logistics.”

The two companies initially connected in 2019. “We sat with Fibox to learn about their pain points,” says Ryan Polakoff, president of Nexterus.

Like many manufacturers, Fibox wanted to focus on its core competency—making enclosures. Yet, they were spending time overseeing raw materials purchases from overseas, while also selling to a range of customers.

When working with a customer, Nexterus focuses first on “what hurts the most,” Polakoff says. They implement a solution to address that, before moving on to other solutions. With Fibox, that meant an initial focus on parcel and domestic less-than-truckload shipments.

Nexterus also armed Fibox with its transportation management system, BrillDog, while its 24/7 customer service team acts as an extension of the Fibox logistics team. In addition, Nexterus handles all kinds and sizes of freight—key for Fibox as their products can range from parcels to over-sized.

The two companies meet every 60 days to review freight data and brainstorm ways to improve shipments.

By working together, Fibox has been able to leverage Nexterus’ relationships with carriers across the country to handle logistics and mitigate costs. When Fibox’s growth prompted a need for additional warehouse space, Nexterus’s relationships and expertise allowed them to effectively negotiate for that space.

Communication, collaboration, and transparency are critical to any relationship, whether you’re working as a vendor, a partner, or a customer, Polakoff says. “The more you can talk and share problems, the better the output in designing processes and solutions that work for everyone.”

Made to Order: BaubleBar and SnapFulfil

BaubleBar, founded in 2011, offers fun, often whimsical jewelry, phone cases, and other accessories, many of which can be customized. Its products are found both online and in major retailers, including Bloomingdales, Nordstrom, and others.

When BaubleBar initially connected with SnapFulfil, a provider of warehouse management solutions, it was looking for a warehouse solution that would be both “out of the box” or have native capabilities that it could adapt into BaubleBar’s fulfillment strategy, while also being flexible enough to allow BaubleBar to custom-build processes for different aspects of its business, says Maritza Mejia, senior operations and customer care director.

She and her colleagues found that many of SnapFulfil’s native capabilities fit seamlessly into BaubleBar’s business-to-consumer strategy, while also allowing the company to streamline some workflows for its business-to-business operations; these had been a source of growing pains with an older system.

BaubleBar currently uses SnapFulfil’s warehouse management system for its domestic fulfillment and inventory control needs, including both business-to-business transactions, such as those with retailers or partners like the NFL, and its business-to-consumer fulfillment.

Consultative Approach

SnapFulfil helps customers across a range of industries manage inventory and fulfillment, says Charles Thompson, project manager with Synergy North America Inc., the company behind SnapFulfil and other solutions.

SnapFulfil uses a consultative approach and brainstormed with BaubleBar on how to modify the system for the company’s made-to-order business line. This includes jewelry, phone cases, and other items personalized with customer names and initials and in other ways.

For the first time, employees are able to pick unique items and track individual purchase orders, inventory, and order fulfillment through the warehouse management system.

As it was working on the SnapFulfil implementation, BaubleBar also re-platformed its front-end website and added an enterprise resource planning (ERP) solution. Implementing several systems at once brings both pros and cons.

“In some respects, it’s easier because you’re starting with a clean slate, but it’s also risky,” Thompson says. Normally, when a company launches one system, everyone can focus there, and be ready to jump in and address any challenges. With this, everyone involved had to be mindful of all the solutions being implemented.

“Through the whole design session, we had to make sure nothing was missed, and understand how one component may have knock-on effects to other components,” he says.

“The SnapFulfil team was thoughtful and mindful of our unique business needs,” Mejia says. BaubleBar was able to book working sessions with its project manager and team members to discuss and work through the various issues prompted by implementing three systems.

It helped that BaubleBar had super users engaged from start. By the time the solution went live, they had been using the product for months in a testing capacity and were very familiar with it.

At the end of 2022, BaubleBar finished its peak season, enjoying a massive spike in sales within its made-to-order program. This was also the company’s first holiday season using the SnapFulfill solution.

“We have a lot of key learnings to help us optimize this portion of our business and we rely on the SnapFulfil team to help us tweak and realign our warehouse management solution to keep up with this spike in demand,” Mejia says.

BaubleBar has also seen dramatic improvement in its key performance indicators (KPIs) for picking operations in its business-to-consumer finished goods and business-to-business fulfillment rates. For instance, the single unit order pick rate jumped from about one per minute to 2.5 per minute.

“This alone helped us drastically improve pick rates during the height of the holiday season,” Mejia says.

BaubleBar plans to work with the SnapFulfil team to make further improvements to its made-to-order business, and to build out additional features to help improve its business-to-business operations, Mejia says.

Capacity for Savings: Cooper Standard Automotive & EASE Logistics

Cooper Standard Automotive, based in Northville, Michigan, and with operating locations in 21 countries, is a global supplier of sealing and fluid handling systems and components.

“I had a specific need for additional carrier capacity on a high-volume lane between two difficult markets, says James Sites, transportation manager with Cooper Standard Automotive

Sites turned to EASE Logistics. From there, the two companies have partnered on more dedicated full truckload lanes and expedited business.

Cooper Standard initially onboarded using emails only. As the relationship has grown, Cooper Standard and EASE have begun using EDI to transmit information between the two companies’ transportation management systems. Additional implementation steps included alignment of billing processes.

The most important pillars in transportation are meeting the customers’ expectations at a competitive cost, Sites says. By partnering with EASE, Cooper averages a 98% on-time delivery rate, Sites says.

In addition, over the seven years the two companies have worked together, Cooper has saved about $5 million. “Loads are transparent, communication is fast, the value is evident,” he adds.

“With tens of thousands of asset-based trucking companies, it’s difficult for any one customer to effectively manage all these relationships,” Sites says. “Working with EASE Logistics allows us to filter this landscape and leverage their capabilities to find timely capacity and at a competitive price.”

Cornerstones of this relationship are, says Benfield of EASE, “effective and transparent lines of communication, and execution of shipments daily.”

The Key to treasured Partnerships

A few features form the basis of successful relationships between logistics providers and their clients.

Solid and honest communication is crucial. By providing information on operations, growth, and seasonality, shippers help logistics providers, who can use this data to design storage solutions, material handling equipment, automation, and labor requirements. This data also helps in developing pricing and appropriate operational metrics.

Manufacturers that have implemented a robust production planning system, or e-commerce retailers invested in sophisticated order management systems need to make sure their logistics provider(s) can properly integrate with the systems they have.

While technology is critical, beware of technology for its own sake. “Automation should be used to reduce the overall labor requirements of the logistics provider’s operation while increasing productivity, picking accuracy, and performance,” says Steve Simonson, vice president, Tompkins Solutions.

Consider the flexibility a logistics provider can offer in terms of space and labor, as well as technology. Flexibility in these areas can enable quick reactions to changes in your business.

Keep customer service in mind. An experienced, responsive, and diligent customer service team can keep goods or shipments from being held up or your internal team from becoming overwhelmed with exceptions and fire drills.

Consider the insight and ideas the provider can offer such as analyzing past split shipments and offering to delay some cargo to avoid extra charges without affecting the production or replenishment process, or analyzing and optimizing the transportation network.

Logistics providers can also provide insight on market conditions and key supply conditions changes, such as labor shortages and rate increases.

What’s Up with 3PL Warehousing?

Labor, Capacity, and Technology Trends

3PLs performing omnichannel fulfillment saw greater success related to order volume and profitability growth as compared to other 3PLs, according to the third annual Third-Party Logistics Warehouse Benchmark Report from Extensiv (formerly 3PL Central).

Additional key takeaways from the 2022 report include:

An increasing number of 3PLs grew volume and profitability. 3PLs fared even better than in past years, despite concerns about inflation, more significant labor constraints, and global uncertainty. 91% of 3PLs grew order volumes in 2022, up from 85% the year prior. 81% claimed higher profits this year, a slight increase from 79% last year.

Omnichannel strategies drove faster growth. 18% of 3PLs performing omnichannel fulfillment saw a 50% increase in profitability over the prior year, which is 33% more than the average of other 3PLs.

Successful 3PLs started to focus. This year, many 3PLs found success focusing on their strengths. For example, more 3PLs specialized in specific industries, with 3PL warehouses serving 2.9 industries—down from 3.5 industries last year.

Labor shortage compounded by increasing labor costs. 48% cite finding and retaining workers as a top business challenge that was also magnified by 79% of 3PLs stating that their labor costs increased in 2022.

Connectivity-led 3PL technology investments. EDI (51%), shopping cart (48%), and marketplace (25%) integrations showed major jumps from prior years as top technology integrated with warehouse management systems (WMS).

More than half of 3PLs fulfill orders in less than 90 minutes. To meet growing customer expectations, 60% of 3PLs fulfill orders less than 90 minutes after receipt, up from 53% last year. Further, the speed of order fulfillment is linked closely with annual order volume growth. Nearly one-third fulfill orders in less than 30 minutes, up from 22% last year.

3PLs focusing on functionalities that drive profitability. The top functionalities respondents plan on implementing in the coming year include billing and invoicing (32%) and mobile barcode scanning (27%). Top priorities include acquiring new customers, e-commerce growth, and automating processes.

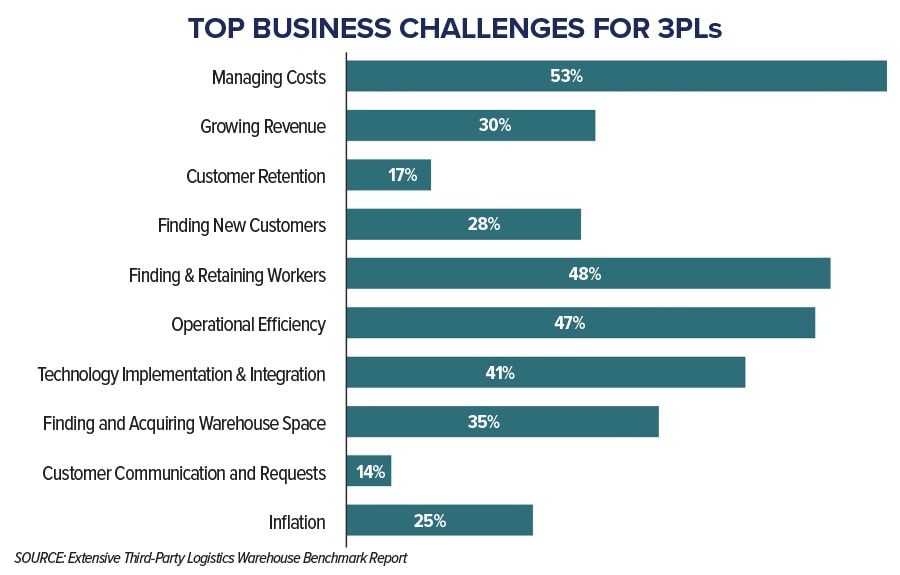

While many 3PLs expect the positive momentum to continue in 2023, the top three potential challenges they see on the horizon include managing costs (53%), finding and retaining workers (48%), and operational efficiency (47%). Last year, operational efficiency ranked as the largest challenge and has dropped slightly based on costs and labor concerns. The most dramatic increase year-over-year came from finding and acquiring warehouse space, which jumped from 21% in 2021 to 35% in 2022.