Discrete Manufacturing: Definition, Benefits, and Examples

In the past, manufacturing tended to involve long assembly lines with armies of workers playing a part in creating the finished products. This description fits well for conventional manufacturing industries. However, with rapid technological advancements, various alternative manufacturing options exist now.

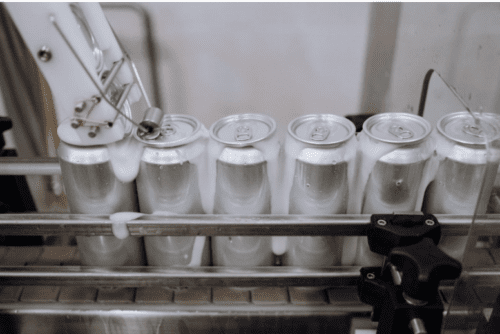

Discrete manufacturing is one of the most prevalent manufacturing processes that utilize a production or assembly line. This production method creates finished products with raw materials or parts you can disassemble.

In this article, you’ll learn about discrete manufacturing, including examples, benefits, and drawbacks.

What Is Discrete Manufacturing?

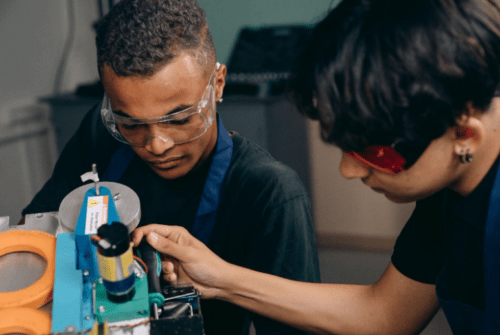

Discrete manufacturing involves creating finished goods by assembling parts you can easily see, count, or touch. Manufacturers using this production process typically assemble parts to create subsystems or finished products. The assembling and production processes are part of discrete manufacturing.

In discrete manufacturing, several workstations throughout the production line produce distinct components, parts, materials, or subassemblies, to be put together at the end of the production cycle to create the final product.

This manufacturing process results in final products that are unique from each other and countable. Additionally, it often creates finished products that may be disassembled into their components and recycled. Some of the industries that use discrete manufacturing include:

- Toys

- Airplanes

- Mobile phones and electronics

- Furniture

- Automobiles

- Textiles

However, manufacturing most finished products involves discrete and process manufacturing operations. For instance, take the case of glass bottle production. You must first create the glass from raw materials using process manufacturing operations before producing individual bottles through discrete processes.

Through the various phases of the industrial revolution, discrete manufacturing techniques and technology have advanced, from handcraft manufacturing to mass production, computer mechanization, and autonomous systems.

Key Features and Benefits of Discrete Manufacturing

All subsectors in discrete manufacturing have a standard production factor; they implement their production process alongside manufacturing enterprise resource planning (ERP) software. Discrete manufacturers use this software to manage and integrate critical aspects of their production businesses.

ERP solutions are typically customized to meet the specific needs of your discrete manufacturing subsector. However, regardless of the manufacturing process you venture into, there are primary features your software should contain.

Features of Discrete Manufacturing

Here are the key features of discrete manufacturing.

Bills of Materials

Discrete manufacturers utilize bills of materials (BOMs) to list all the raw materials, sub-assemblies, parts, and quantities of each production material required to manufacture the final product.

In a bill of materials, you can dissect discrete products into their constituent components, just like recipe ingredients in process manufacturing. You can also have multiple BOMs for a single final product, depending on the product’s complexity.

The main challenge of BOMs is revision control. You can make tracking production changes easier by having a centralized list of all the components that go into your BOMs, including the associated costs of producing the parts and the production duration.

Production Planning

Production planning is an essential and multifaceted aspect of discrete manufacturing operations. It begins with a top-level demand plan specifying the production quantity and intervals. Then, production scheduling further specifies which components of final products you will manufacture on certain production lines and runs.

Forecasting, scheduling, and capacity planning are essential components of a larger production plan that your ERP can help you manage in a manner that maximizes production efficiency. However, the primary challenge of production planning in discrete manufacturing is ensuring your ERP solution can coordinate all factors of production with production timelines.

A reliable, discrete manufacturing ERP software can modify the production plan dynamically by combining production resources and inputs while evaluating cycle periods against your scheduled delivery times.

If you continue to depend on older technology systems for planning and scheduling, your production lines are likely to have glitches. Real-time data and comprehensive analytics, which can only be created by modern software, are necessary for advanced production scheduling.

ERP consolidates all your data into a centralized hub, providing essential information to help you speed processes and minimize bottlenecks. Using this information, your ERP can create efficient schedules that streamline production.

Inventory Management

Inventory management involves managing the volume of raw materials that are delivered and available at your worksite. Your material handlers must ensure raw materials and appropriate assigned quantities are available. They then execute the materials movement transactions in the ERP software. These steps are critical to operating your discrete manufacturing plant correctly. Keeping an eye on your inventory is an effective way to avoid unexpected shortages or unplanned downtime.

Discrete manufacturers face several issues regarding inventory management. The most common challenge is ensuring inventory changes are appropriately documented in ERP systems.

If your handlers transfer material, discard components, or fail to record production, the ERP software will be out of sync with the accurate inventory position. It will result in significant production and production planning issues.

Quality Control

Scrapping and rejects are typical in a discrete manufacturing process resulting from operator or machine error. In this sector, there are industry-specific and regulatory requirements. In order to be compliant, a company must use quality control management processes to prevent unfinished products from reaching customers.

Quality compliance requires that discrete manufacturers document their production processes, equipment, and remedies. In this case, a quality management system (QMS) can assist companies in meeting industry compliance requirements.

A reliable ERP solution for discrete manufacturing will effectively boost your quality control efficiency by featuring a QMS that can track simple and complex regulatory requirements, including corrective and preventative actions (CAPA) and failure modes and effects analysis (FMEA). Such a system helps ensure you comply with industry regulations and meet consumer expectations.

Supply Chain Management

In discrete manufacturing, supply chain management is critical to the efficiency of your operations. Not monitoring for inconsistencies in production, products, resources, human capital, and other factors might affect your company’s profitability in the long term.

Acquiring a supply chain management system or a standalone discrete manufacturing ERP software with a supply chain management module provides many perks, including:

- Managing expenses in your operations

- Facilitating the on-time shipping of final products

- Fostering healthy relationships with suppliers

Benefits of Discrete Manufacturing

Here are the advantages of discrete manufacturing.

Strengthened Supplier Relationships

Obtaining materials is critical for most discrete manufacturers, so maintaining good relationships with your suppliers is important. Discrete manufacturers cannot guarantee the quality of the components and raw materials they acquire from suppliers, a task made more challenging if the suppliers are worldwide. ERP software can be used to verify that your supplies are satisfactory.

Enhanced Productivity

Most discrete manufacturing ERP solutions include real-time key performance indicator (KPI) metrics to indicate possible production bottlenecks. With automated data capture (ADC) technology, the ERP solutions provide visibility into suppliers, logistics costs, expected market demand, and potential competition.

Increased Customer Satisfaction

The bottom line of every discrete manufacturing venture is keeping consumers satisfied. Consumer satisfaction affects the performance and profitability of your discrete manufacturing company. Therefore, a discrete ERP should feature a customer relationship management (CRM) system.

A CRM system helps to provide accurate consumer information, product details, order status, and progress reports. You can use this information to meet your customers’ expectations and make accurate sales projections.

Drawbacks and Limitations of Discrete Manufacturing

The primary downside of discrete manufacturing is its immense complexity, the need to manage many details, and the limited flexibility to make production changes.

In addition, this process has various distinct production lines for each component or finished product. Also, establishing a discrete manufacturing plant is capital-intensive and requires up-front expenditures and resources.

FAQs

We have addressed all you need to know about discrete manufacturing. Now let’s dig into some frequently asked questions.

What are examples of discrete manufacturing?

Discrete manufacturing involves the production of distinct goods. Here are some examples of discrete manufacturing:

- Computers

- Cookware

- Vehicles

- Smartphones

- Cabling

What is the difference between discrete and process manufacturing?

The primary difference between discrete and process manufacturing is the method of creating the final product. Process manufacturing depends on clear-cut formulas or recipes to create the finished product through an irreversible process. Conversely, discrete manufacturing features distinct unit production with components that can be disassembled.

What is the difference between discrete and continuous manufacturing?

Process manufacturing is also known as continuous manufacturing so the same differences apply between discrete and continuous manufacturing.

Final Thoughts

Discrete manufacturing has many distinctive characteristics that set it apart from other manufacturing processes. The key to discrete manufacturing performance is harnessing data to ensure quality and efficiency.

As a discrete manufacturer, you’ll want to find ERP software that meets your industry’s needs, including your company’s operations and demands. When built on a common platform, a discrete manufacturing ERP solution can reach throughout your organization, including CRM, and link after-market services and field service management.