Sorting Through Materials Handling Decisions

What happens in the warehouse no longer stays in the warehouse. Today, optimizing materials handling equipment and processes inside the four walls starts at the top, and impacts the entire supply chain.

Materials Handling Innovation in Action: Cruze Control

Supply chain network design. Optimization. Alternative sourcing. How procurement works with physical distribution. The impact of multiple facilities on inventory. Consolidation strategies. These factors, and many more, affect distribution center operations. Optimizing inside the four walls may start far up the supply chain.

For example, once you know where your distribution centers will be located, you want to ensure you have the right amount of inventory in the right place to achieve proper service levels. “Effective network optimization can save up to 15 percent of facility and transportation costs,” says Paul Evanko, senior vice president of St. Onge Company, a supply chain consulting firm based in York, Pa. “Include inventory optimization, and you can save another five to 15 percent.”

Even packaging comes into play when making materials handling decisions. Increase your products’ value density and you can add another three to 30 percent in savings, depending on product value. Consider Hewlett-Packard (HP). When it redesigned packaging for a notebook computer, it reduced the product’s weight by eight percent and increased the number of cases per pallet by 25 percent.

Bottoms Up

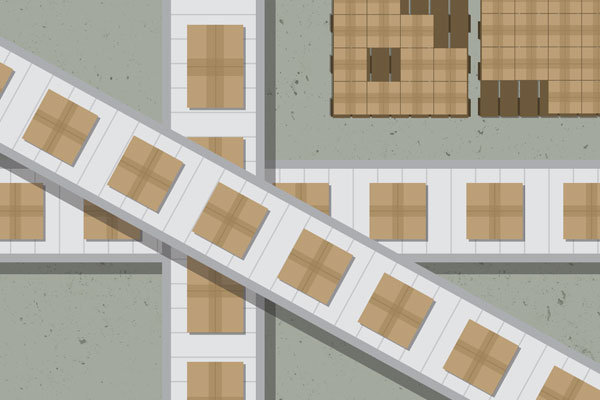

Starting at the piece level, then working up to the layer and pallet levels to optimize each element of materials handling, can result in better stacking, less overhang, and less damage. It also opens up some options, such as the ability to use machine loading rather than hand-stacking.

It’s a quick descent from 10,000 feet to ground level. Decisions on where to source, or how many facilities to operate and where to locate them, play into the facilities’ basic operations and demands on their systems and processes.

For example, HP’s packaging change could add layers to a pallet, altering its storage and handling characteristics. Less pallet overhang might allow for the use of automated storage solutions, which had previously posed too much risk of damage. Storage location configuration may also need to change to accommodate larger, heavier pallet loads as more items are added to each pallet.

Similar materials handling changes might come into play on the outbound dock. More efficient trailer utilization can be a plus, but more product in the same trailer can spell higher transportation costs as a result of the shipment’s added weight and value, and greater risk in the event of a loss. And, the denser pallet load is bound to affect receiving, storage, and picking operations at the next stage in the supply chain.

Small changes can add up to major savings— or major headaches. If you want to shave a few seconds off picking operations, for instance, it’s important to look upstream and down in the process. “The last thing you want to do is improve step one and, as a result, steps two and three can’t handle the load,” notes Nathan Beene, director, logistics engineering for Kenco Logistic Services, a Chattanooga, Tenn.-based third-party logistics provider.

Unclogging Bottlenecks

Companies usually consider automating their distribution facilities to address bottlenecks. “If you want to improve a bottlenecked process, you need to evaluate the process that leads up to it; don’t starve the bottleneck,” explains Beene. “If a conveyor upgrade can improve takeaway in the picking area, then look at the picking operation.

“If you can only get things to the line at a certain rate, that’s all the automation will be capable of doing,” he adds. “The systems feed off each other, so find small improvements that benefit the whole.”

Automation investments

What’s the true value of your investment in automation? Productivity gains, flexibility, throughput, accuracy, and increased service levels all count when considering what investments today will support near-term gains and drive long-term performance.

“You also need to shift your focus from total cost of ownership, a common way to evaluate a capital investment, to total value of ownership,” says Tony Barr, vice president of marketing and business development for Beumer Corporation, a materials handling firm providing conveying, loading, palletizing, packaging, sortation, and distribution systems.

Under the total-cost approach, productivity and throughput are considered part of the structural improvements an automation project can deliver. Then add flexibility, accuracy, and service levels, which support volume growth and margin expansion. These improvements can shorten the time frame for return on investment (ROI) and enable growth, according to Barr.

Productivity gains typically result in picking and packing labor reductions, which is commonly a major consideration in cost justification/ROI. “But a second consideration is often throughput— do more with less, maximize volume, and minimize time,” adds John Sarinick, vice president, Beumer Corp.

Space can also be an issue. Automation can help expand an existing facility’s serviceability; it can also provide flexibility. “Use sortation to allow areas in the DC to have multiple uses,” Sarinick recommends.

Another benefit of automating your distribution center can be improved accuracy— on-time and correctly filled orders— and enhanced customer service levels.

That’s the result MBS Textbooks, a Beumer customer, achieved when it turned to automation. The 100-year-old company, a division of Barnes & Noble, is the country’s largest used-textbook wholesaler. On the wholesale side of its business are campus bookstores; on the retail side, MBS is expanding into direct-to-consumer sales. A third element of its business is bookstore management systems, such as point-of-sale and inventory management.

MBS operates one 350,000-square-foot distribution center in the only home the company has known— Columbia, Mo. The facility receives 2,500 to 3,000 packages per day, and ships 3,000 cartons daily. It holds 120,000 titles in stock at any given time, and serves a 2,600-bookstore customer base.

One problem MBS faced when managing the rapid growth of direct-to-consumer sales was that the business didn’t fit the traditional wholesale fulfillment process. The retail portion (direct-to-consumer) was automated in 2000, and expanded again in 2003 to handle 1,300 orders in a dynamic batch fashion. The company undertook a third automation project in 2007 to keep up with retail segment growth. Over the past 10 years, this business has grown 300 percent.

“We needed flexibility, accuracy, and the ability to streamline internal processes,” says Mike Pitt, director of automation for MBS Textbooks.

Wholesale orders were being picked into shipping cartons, while retail orders were picked into two different colored totes. This presented a challenge in getting the right carton or tote to the picker at the right time. Part of the solution was simple: MBS started picking all orders into shipping cartons and eliminated the totes.

Cartons that contain wholesale orders proceed to a sortation line, where they can be automatically taped shut. Retail orders are removed from the carton that carries them through the sortation process, and the carton returns through the system to be loaded again with either a wholesale or retail order.

MBS sized the system to handle 20,000 items per hour and 450 processing destinations. All outbound processing destinations look alike, allowing them to process either wholesale or retail orders.

“One order can be sent to multiple processing destinations or multiple orders can be sent to one processing destination,” says Pitt. This limited the size of equipment MBS needed to purchase, he notes, and allows for future expansion. Picking to a static batch and eliminating some processes (and the number of times a product was touched) boosted productivity by 35 percent.

Applying Manufacturing Principles

Shekar Natarajan, director of supply chain operations for The Pepsi Bottling Group Inc., sees a trend toward extending manufacturing principles and efficiencies from the way a company builds its product to the way it builds orders.

“Take the work back to where it naturally belongs— in distribution,” he says. “Use manufacturing-like systems and technology to create custom orders.”

Treat labor as you would any significant asset, agrees Louis Cerny, vice president of Sedlak Management Consultants, a Cleveland-based supply chain consulting firm. “Review current labor practices, identify best practices, revise poor practices, develop and update standard operating procedures, and train associates,” he suggests. “And use the labor management module in your warehouse management system, or add the capability.”

The top 20 percent of SKUs in your facility represent 80 percent of the volume; the bottom 40 percent of SKUs comprise five percent. Walking takes up about 70 percent of picking time. Look for ways to improve performance by reducing walking time. Don’t make pickers constantly walk past slow movers to get to fast movers, or consider bringing the picks to the picker using carousels or mini-load systems.

Look Up and Down

Avoid taking a small-scope approach. “Companies often look at how they can improve one part of a process without looking upstream or downstream,” Beene notes. “You might, for example, identify a problem in getting the product to the automation. If you improve just that process, the entire system would work much better.”

Suppose you add a take-away conveyor to a picking area to speed processes. The actual picking could still constrain throughput. Improving the picking process could bring the operation closer to the conveyor’s capacity.

Beene suggests a process improvement that was implemented at one of Kenco’s distribution centers.

Pickers were using handheld scanners to record transactions in the pick area. Kenco replaced the handhelds with wrist-mounted scanners, and pickers eliminated the steps of picking up the scanner, scanning, then putting the device down to pick up the item being picked. Using the wrist scanner freed both hands to handle the product. The 1.5 seconds this saved may not sound like much, but, “depending on the volume you are picking, it can make a difference pretty fast,” Beene says. Switching picking operations to wrist-mounted scanners delivered ROI to the DC in a few weeks.

Another element of improving materials handling processes is developing and adhering to corporate best practices. Through experience, Kenco has developed procedures for receiving, picking, and other functions that become part of a baseline process to measure against. Some of these procedures can become “templates” to build with when setting up a new operation.

The Human Touch

Employee-related costs eat up a good portion of distribution center budgets. That’s why making lift truck operators and other warehouse employees more productive is crucial, says Tim Quellhorst, senior vice president of forklift manufacturer Crown Equipment Corp.

Like Beene, Quellhorst recommends optimizing the human-machine interface. For example, visibility, good controls, and operator comfort all contribute to lift truck optimization. Improved vehicle productivity and performance can help require less from the operator.

“Companies are looking for productivity, energy efficiency, and ecology, as they relate to each other,” says Quellhorst. “It’s not about achieving maximum productivity in one area that would negatively affect other areas.”

Increasingly, every tool in a warehouse contributes to knowledge management. Crown’s InfoLink fleet management system, for instance, helps ensure safety and adherence to performance standards, and optimizes equipment serviceability. These types of intelligent systems help ensure that only authorized operators are able to use specific pieces of equipment.

In addition, intelligent systems can be programmed to require safety inspections, and on-board impact sensors can help identify unsafe practices and reduce damage.

Technology improvements and operator input can boost lift-truck efficiency to higher levels. New battery technology, for example, improves lift-truck run time and reduces charging times. But in a facility maintaining a large fleet of lift-trucks, the bottleneck occurs at the charging station.

One way to break that bottleneck is to implement a “pony express” process, where operators take their lift-trucks to the charging station, then climb into a waiting lift-truck that has been charged, fully checked, and is ready to go.

To avoid congestion at the charging station, drivers are directed to take their lift-trucks out of service on a staggered schedule. If a shift starts at 7 a.m., you don’t want all the operators showing up at the charging station at the same time when all the lift-trucks are reaching a similar level of discharge. Like the legendary delivery service, there’s always a “fresh mount” available for a driver.

Show and Tell in the Warehouse

With tens of thousands of available applications, and the ability to stream live video on a smartphone, it’s time for shop floor devices to play catch up. Efficiency gains in warehouse management systems peaked about 10 years ago, says Peter Brereton, founder and chairman of TECSYS, a global warehouse management software provider.

In a warehouse, the administrative offices typically operate in English, but the warehouse floor may host a variety of languages and literacy levels. Add temporary, seasonal workers to the mix, and the challenges to maintain efficiency and accuracy rise exponentially.

In a warehouse’s contained environment, putting wireless radio-frequency devices in the hands of workers or mounted on their lift trucks to provide real-time interaction with planning and inventory control systems has solved many problems. Adding tethered and untethered scanners moves forward another step in eliminating some picking and putaway errors.

A Look at Visual Logistics

While these systems can direct warehouse workers to the proper location, then verify through a scan that they have arrived at the correct slot, errors can still creep in.

For example, when the device directs a worker to “pick one,” what does that mean? In a broken case area, it might be clear that “pick one” means one item. But, if the case isn’t open, does it mean pick one case?

Enter visual logistics. Using a Psion Teklogix Workabout Pro 3 handheld terminal with a full-VGA display, the TECSYS Visual Logistics warehouse management system sends an image to the worker to positively identify the item.

Visual logistics has helped increase throughput by 15 percent, reduce materials handling by 70 percent, cut annual physical inventory time by 50 percent, and reduce defects by 96 percent, according to TECSYS customer reports.

For one customer, North Mississippi Health System, the EliteSeries 8 Visual Logistics system increased the number of in-stock items by 47 percent without adding people, reduced mis-picks by 71 percent, increased fill rate to 99.98 percent, and achieved an $8-million annual cost reduction.

Dramatically improving graphics capabilities of shop-floor devices is only part of the story. While many applications use enhanced text displays to avoid ambiguities, a visual diagram of the pick face highlighting the picking location gives the operator a positive target. Following that with an image of the item and the number to be picked further reduces errors. Because the system is server-based and communicates in real time via radio frequency transmissions, it can even stream a five-second video showing the operator how the items picked are to be packed.

“Reducing errors results in substantial savings,” explains Brereton, “especially in fields such as healthcare, where errors carry high costs and high risks.”

People, Process, Technology

Getting smarter about materials handling means looking at people, process, and technology. Kenco’s Beene suggests looking at your current process, taking a lean approach to identify opportunities for improvement, and asking if the gains expected from a capital expenditure justify the cost. Gather your research on the issues you want to address with the capital expenditure to prove the business case.

Most importantly, don’t wait for management to approve your capital expense to start process improvement efforts. Get your processes in order to ensure a smooth transition. That way, even if the capital budget isn’t approved, you are already making gains.

Materials Handling Innovation in Action: Cruze Control

Optimized materials handling operations and tight inbound control keep Chevy Cruze production lines moving, despite GM’s stringent quality standards that demand error tolerances smaller than the diameter of a human hair.

General Motors’ introduction of the Chevy Cruze to North America got the auto industry talking. It also created a lot of buzz in Lordstown, Ohio, where its predecessor, the Cobalt, had been assembled. The region worked hard to attract the Cruze to the Lordstown plant. Once GM came on board, the transition pace picked up dramatically.

The Cruze represented more than just a model changeover for Comprehensive Logistics Inc. (CLI), a third-party logistics provider of warehousing, distribution, and transportation management services based in Youngstown, Ohio. It is the third GM vehicle CLI has supported at the Lordstown facility in a decade.

CLI, which provides both contract manufacturing and third-party logistics services to the GM plant, was called on to play additional roles as GM consolidated its suppliers. The value-add contract manufacturing segment —representing about 140,000 square feet of a total one million square feet of space in four facilities —started operating three shifts almost immediately.

GM’s Cruze had established a strong market presence in Europe and Asia, which made sourcing some parts and components a challenge for the inbound supply chain because suppliers were busy producing to meet demand in those markets.

QUICK CHANGE ARTISTS

Planning for the change started well in advance of the last Cobalt rolling off the line, and it wasn’t long before the first Cruze left the plant. The changeover happened quickly. CLI started putting together its Cruze lines in December 2009 while the Cobalt was still running at the GM plant. It supported the Cobalt until June 2010 when the Lordstown plant started producing Cruze models. It soon ramped up to about 1,000 vehicles per day.

“It all starts in receiving,” says Steve Olender, CLI’s vice president of information technology. CLI receives all its information through the same proprietary system, which executes a plan for every part. CLI handles crossdocking, deconsolidation, sequencing, subassembly, repacking, and bulk parts storage for the Lordstown Cruze assembly plant, and it delivers just-in-time.

Because some components are sourced internationally, CLI also receives and strips more than 30 ocean containers daily, although volumes vary. While GM handles sourcing, CLI receives advance ship notices on supplier shipments, as well as broadcasts from GM on what it is building and which parts and subassemblies it needs.

If a part needs to go directly to the GM assembly plant to be built into a subassembly, that’s what the destination routing will read. “The part can be loaded onto an outbound truck for delivery in the specified time window as soon as it is scanned in receiving, and a lot label is applied, then rescanned for routing directions,” explains Olender.

In receiving, all items are scanned using an Intermec Windows Mobile 6.1-based device. The operator scans the supplier part label, and a portable printer generates the appropriate lot label while the operator receives destination routing instructions.

“Lot control is important,” says Olender, “because CLI needs to ship the parts in first-in, first-out order. In addition, a particular part might need to be inspected prior to being delivered to the assembly plant.”

An outside firm handles inspections when required. Parts needing inspection are routed to the contractor when they arrive in receiving. Otherwise, they move either into storage, to the CLI assembly line, or directly to the GM line. “The goal is to deliver only 100-percent certified parts lineside,” says Olender.

How well is the system working? “We operated 54 weeks without a mistake,” Olender notes.

QUALITY DOWN THE LINE

Quality doesn’t stop with receiving the right part at the right time and delivering it to the right destination in storage or in the plant. Once the supplier serial number is scanned and associated with the lot number, it is traceable throughout the process.

Processes are also engineered, measured, and recorded. For instance, the torque values are set and recorded so that they are associated with a particular assembly. This, in turn, is linked to the vehicle identification number (VIN) in the build order so that essentially every part, its supplier, and each process and person associated with building that vehicle is part of the car’s pedigree.

Inside CLI, checks and balances ensure compliance. The headliner assembly area hosts 13 stations, 15 workers, and four robots. Headliners have 48 variations each for the U.S. and Canadian markets. A pick-to-light system directs an operator to the next headliner to be selected. When the operator picks up the component, the act of breaking a light beam indicates to the system the item has been picked.

Vision systems on the line and associated with the robots check 33 critical areas for location, presence, and orientation as the subassembly progresses through manufacturing and when it is ready to leave the line.

The system won’t allow the operator to pick from the wrong lot or wrong location. It can be set up to allow the operator to make a correction or initiate a hard stop, which would then require a supervisor override to continue. Either way, error corrections are closely watched and root causes examined.

Portable label printers help reduce errors in receiving. The inbound parts are scanned against the advance ship notice or receiving documentation, and a label is printed and applied before the operator moves to the next item.

“If it weren’t done that way, the operator might go down one side, scan the items, then go back to a printer and retrieve a strip of labels and stick them on,” says Olender. “This could allow errors, so the process is designed to minimize the risk of a mistake.”

Some larger assemblies move in specialized containers. They are loaded in reverse sequence, so CLI needs to receive the last sequence for the rack before starting to build the subassembly. Containers have bar-coded identities and include identification for each slot on the container. Parts and assemblies are scanned and placed into a slot that has been scanned for confirmation.

A similar process occurs at the outbound dock door, and trucks bound for the customer assembly plant can’t leave with an open order. An open order condition can exist if a container is put into a different trailer, even if it is bound for the same destination.

“Two trucks leaving at the same time might encounter traffic, causing the second truck to arrive first,” Olender says. “As added protection against containers moving out of sequence, orders are kept together.”

VEHICLE TRACKING

The truck operations controls are similar to a passenger airport. The systems track what vehicle is at which door and when and where it is going. It even counts down the time to departure. It verifies that only the product that matches the destination is allowed to enter the door and get loaded into the trailer.

Every few seconds, CLI receives broadcasts and orders from the GM plant; it is up to the 3PL to translate this data every minute of every day into what it is feeding the assembly line. CLI can see the line and what is being built and consumed.

CLI’s contract manufacturing operations are synchronized with the plant, but so are replenishment activities. CLI handles 75 to 80 percent of inbound shipments to the GM plant, and where the timeframe for some of the sequencing is as tight as 90 minutes, it also has windows on “commodity” items that could extend to six hours.

Six-hour windows might sound almost leisurely, but they are equally choreographed. CLI is watching for trigger points on when the GM lineside supply of a commodity part matches CLI’s response time. It can then pick and prepare a shipment, and deliver it to the Lordstown assembly plant. Except for some specific items, there is no room for excess storage at the GM plant.

CLI’s own facilities need to maximize efficiency, especially where logistics operations share space with contract manufacturing. This can include the number, type, and application of lift trucks.

Sit-down lift trucks move in the main aisles through the facility’s warehouse and manufacturing areas. But, a narrower aisle serves the actual assembly operations. Here, walkie pallet jacks take the containers or pallets the lift trucks drop at a designated spot and move them to the work station. This saves floor space in the work area. It also reduces injury and damage risk because the smaller, slower, more maneuverable lifts are engaged in supplying the contract manufacturing lines.