Supply Chain Resilience: Overcoming the Obstacles

Organizations draw on resilience planning and impactful technology for the strength to resist the challenges of lengthy supply chains and ongoing disruptions.

Until recently, supply chain resilience wasn’t always top of mind for supply chain leaders. As a result, many companies failed to optimize their supply chains for resilience, choosing instead to focus on efficiency and minimizing costs.

While efficiency and cost control remain critical, resilience is quickly moving up the list of priorities. Holding back the many obstacles faced by today’s supply chains is now a must-do.

“As companies grapple with economic and geopolitical uncertainties on a global scale, the imperative to construct resilient supply chains is more pronounced,” says Elizabeth McGuire, director and supply chain lead with Clarkston Consulting.

To meet this goal, supply chain leaders can turn to a range of technology tools—artificial intelligence, digital twins, interconnected platforms, and mobile robots—among others.

Challenges and market fluctuations have always been a constant for supply chain operations. “Geopolitical actions, regulations, and policy are always in a state of change, while natural disasters, global conflicts, and threats from various supply chain nodes continue to ebb and flow,” says Mary Rollman, supply chain leader with KPMG.

What has changed is the intensity and frequency of these challenges. As supply chains become more global, they are more likely to be impacted at a global scale when local events occur.

In addition, the ecommerce boom of the past few years means many brands are competing with a seemingly limitless pool of companies. Carrying a massive range of inventory may be key to remaining in the game. However, the expanding volume of SKUs (stock-keeping units), as well as the range of channels through which many companies sell their products, adds to volatility, says Nate Rosier, senior vice president, consulting with enVista, a supply chain and enterprise technology consulting firm.

As more companies shift some production out of China, they have to adjust to different shipping schedules and lead times, which also can add volatility. Moreover, many companies’ supply chain processes have been cobbled together over time, and “were never designed to handle this much volatility,” Rosier explains.

Leveraging Uncertainty

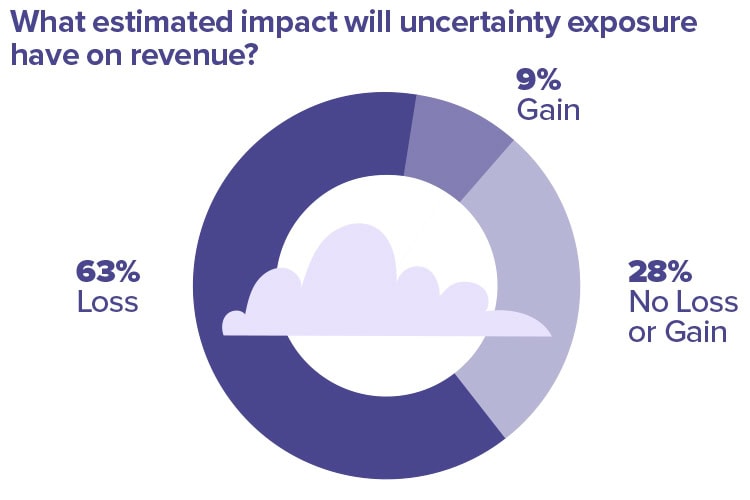

While many supply chain organizations recognize that uncertainty is here to stay, fewer than 10% of companies expect to gain revenue when exposed to uncertainty, according to recent Gartner research.

Supply chain leaders must think about how to prosper in an environment of uncertainty, recommends Tim Payne, vice president and analyst with research firm Gartner. The approaches of the past no longer are enough.

While many supply chains managed disruptions with what Rollman calls “manual muscle,” that approach is no longer sustainable. To do more with less, supply chain organizations need to invest in technology tools.

Many are doing just that, implementing technology such as warehouse management systems, as well as more sophisticated solutions that support the use of data and information to improve decision making. Common investments include the following:

Supply Chain Platforms

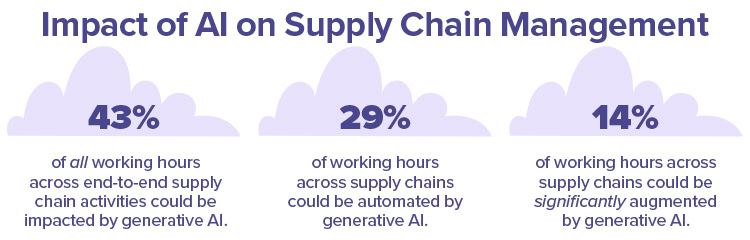

Source: Accenture research report

Platforms can play a key role in supply chain operations. One way companies can increase resilience is by expanding their supply base to multiple vendors, often in different regions of the globe. As they do, a technology platform can provide process controls and a single source of data for their transactions.

These attributes enable process consistency and consequent predictability that bring stability as vendors are added. This, in turn, facilitates supply chain diversification and resilience, says Bryn Heimbeck, president and co-founder of Trade Tech, which offers technology that addresses global trade complexities.

Probabilistic Planning

Working with probabilities—expressions of uncertainty—is a critical tool for shoring up supply chain resilience.

“The more you work with probability, the more knowledge you can gain about how uncertainty impacts your supply chain,” Payne says. With this knowledge, supply chain leaders are better prepared to take advantage of uncertainty.

Conversely, static planning assumes no uncertainty—a largely unrealistic assumption. With no knowledge of the impact of uncertainty on their supply chain, organizational leaders are at risk for making poor decisions about the design and use of agility and responsiveness, Payne says. That leaves their supply chains vulnerable to losing value when exposed to uncertainty.

Several vendors are moving into the market with probabilistic forecasting products, Payne adds.

Advanced Analytics

The category of advanced analytics includes tools that use data science to predict patterns and estimate the likelihood of future events, among other functions, then leverage this insight to address complex business problems.

For example, machine learning capabilities, as part of advanced predictive analytics, can detect previously unrecognizable patterns in data, driving greater certainty in determining how demand will materialize.

Digital Twins, Artificial Intelligence, and Internet of Things

A digital twin can represent one or more supply chain processes designed to help organizations simulate real situations and their outcomes and then make informed decisions.

When combined with Internet of Things (IoT) technology, a digital twin can help employees work in ways that enhance communication, operations, and processes, and boost efficiency, says Rajinder Bhandal, Ph.D., a management lecturer at Leeds University Business School, and a member of the Digital Twin Consortium Academia and Research Working Group.

For instance, the two solutions together can facilitate better quality data and data sharing. The data can be mapped onto multiple supply chain processes where workers interact to provide visibility and improve decision-making.

Linking advanced AI tools with digital twins can also help organizations plan for and adapt to supply chain disruptions. To help in developing robust scenarios and recommendations, the tools should allow for modeling multiple “what-if” scenarios based on changes within the supply chain, and should be able to ingest diverse sets of data.

Generative AI

Currently one of the most buzzed-about technologies, generative AI refers to machine learning systems capable of generating text, images, code, or other content, often in response to a user’s prompt. A primary benefit is efficiency, as generative AI can automate many tasks; Accenture research shows that generative AI could automate or augment up to 58% of supply chain processes.

This enhanced efficiency can lead to greater resilience. For example, an AI-powered interface could help supply chain employees efficiently query and receive recommendations for demand and capacity planning insights in everyday language. With this information, they can quickly prepare for or respond to volatility.

One example of a generative AI supply chain tool is TrusTrace, which offers a traceability and compliance data platform. It uses optical character recognition (OCR) to convert into a standard format the many varied documents that make up supply chains, such as purchases orders and emails. It uses AI to train the OCR software.

With artificial intelligence, the OCR solution can attain 80% accuracy on new documents after just a few days of training—a process that previously would take a few weeks, explains Shameek Ghosh, CEO and co-founder of TrusTrace.

AI-enabled supply chain traceability, an element that has often been a concern for companies working to improve their environmental impact, also can increase resilience by helping companies quickly pivot when needed, Ghosh adds.

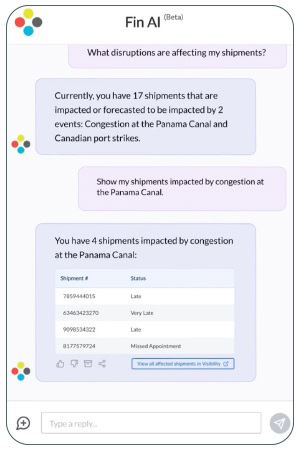

Visibility Solutions

Supply chain visibility tools like this chat bot from FourKites provide shippers with access to critical, end-to-end supply chain data they can use to make faster decisions and stay ahead of disruptions.

Often, transshipment and final destination ports can be “a black hole for data,” says Seth Fredrickson, vice president of product management at FourKites, which offers a supply chain visibility platform. Shipments can get lost due to disjointed communications and confusion. “When disruptions occur, every minute matters,” Fredrickson says.

End-to-end supply chain visibility can lead to better decisions and lower costs. Case in point: Pasta brand Barilla, which operates 30 production sites across multiple countries, uses FourKites’ Dynamic Ocean solution to increase visibility and shipment information for its ocean freight.

By leveraging dependable data and predictive estimated arrival times, among other information, cross-functional teams have access to critical global supply chain data when they need it.

“Before we started using the FourKites platform, we could only react to an issue when it was too late,” explains Davide Busato, Logistic Competence Center Innovation project manager with Barilla. “Now, we react before an issue escalates into a major problem.”

Robots

Autonomous mobile robots (AMRs) enhance supply chain resilience through their efficiency, adaptability, and flexibility, says Jeff Clark, executive vice president with ODW Logistics, which implemented an AMR solution for a national beverage company that was able to almost double its number of units picked per hour.

AMRs can also be swiftly deployed or reconfigured in response to shifts in volume and customer demands. “This agility empowers operations to promptly adapt to unforeseen changes in production volumes or distribution requirements,” Clark says.

Automation

An automation portal enables Montway Auto Transport to centralize order processing, transportation planning, and inventory management so it can respond quickly to demand.

Orchestrating tools, processes, and resources to function more effectively in order to boost supply chain resiliency is one important element of the automation trend.

For example, Montway Auto Transport, as its name indicates, offers auto transport services. Its Montway Automation Portal (MAP) centralizes order processing, transportation planning, inventory management, and other processes.

“This provides a more efficient, data-driven operation that can respond quickly to supply disruptions as well as consumer demands,” says Mike Trudeau, executive vice president of business development.

For instance, car dealers typically source vehicles locally, ignoring more distant markets due to perceived transportation costs. MAP allows them to generate quotes without committing to orders, so they can assess how transportation costs would impact the profitability of potential vehicle purchases. This helps dealers enlarge and diversify their supplier base.

Data Lakes

As a central repository that stores large volumes of data in their original form—whether structured, like spreadsheets; semi-structured, like web pages; or unstructured, like images—a data lake allows data to be processed and used for analysis. Data lakes offer shippers the ability to gain insights into various options that can effectively mitigate future supply chain risks.

Design for Resilience

Source: Supply chain organizations’ response to Gartner research study

Along with technology, thoughtful supply chain design is essential for resilience. “Supply chains are either purposely designed or ad-hoc designed,” says enVista’s Rosier. Purposely designing for resilience means planning for seasonality and fluctuations, and then assembling a blend of fixed and variable capacity to meet demand.

Building supply chains that can withstand uncertainty, however, may no longer be enough. Companies need to consider strategies that can help them learn and adapt so they can gain value from uncertainty. It’s what Tim Payne of Gartner calls “anti-fragility.”

This approach requires stress-testing the supply chain, and continuously asking, ‘If this were to happen, what are options to take advantage of it?’

With the right tools and techniques, companies can embrace anti-fragility and build crucial supply chain resilience to help them face off against the next inevitable challenge.

Small Companies Go Big on Resilience

Supply chain resilience isn’t the sole realm of corporate behemoths. Small and mid-size businesses also need to boost resilience to deal with uncertainty. Here are some tools and processes that can help SMBs firms drive resilience.

1. Low-code development. This method of software development requires minimal coding and offers drag-and-drop functionality through an easily navigable graphical user interface (GUI).

How does this relate to supply chains? “Platforms for low code have made the process of developing new applications very easy for less-technical people,” says KPMG’s Mary Rollman.

One area that has seen a lot of low-code solutions development is supply chain planning. Because these solutions can be personalized, they often enjoy strong adoption, unlike software that requires users to change their processes.

2. Artificial intelligence. Even small companies are getting into AI, says Tim Payne of Gartner. They can start small, focusing on even one specific area that’s causing the most pain, such as transaction history.

3. Software as a Service. SaaS solutions are an affordable option for many companies. With SaaS, companies typically avoid initial hardware costs and benefit from flexible payment options, like pay-as-you-go arrangements.

4. Processes. Organizations of any size can take steps to empower decision-makers so they can make informed choices that contribute to more agile and adaptive supply chains, says Elizabeth McGuire of Clarkston Consulting. These choices include:

- Identifying the business’s most impactful vulnerabilities, such as technology, suppliers, or location.

- Developing a supply base that leverages alternative suppliers or an inventory strategy to support single or sole suppliers.

- Using technology to ensure operations can grow and/or are stable.

- Placing inventory so it’s aligned with product distribution and meets customer service levels, while also reducing the risk of excess and obsolescence.