Just in Case (JIC) Manufacturing: What It Is, Benefits, and Drawbacks

JIC manufacturing focuses on keeping extra stock to prepare for unexpected changes in customer demand or supplier delays. This inventory strategy aims to avoid production delays and ensure smooth manufacturing processes by holding more raw materials and finished goods than usual.

Companies rely on just-in-case inventory to protect against supply chain disruptions and maintain supply chain reliability. Unlike the just-in-time approach, which minimizes stock, just-in-case manufacturing accepts higher storage costs and carrying costs to keep operations steady.

This article will explain what just-in-case manufacturing involves, compare it with other inventory management models, and explore its pros and cons for businesses managing their inventory levels and cash flow.

What Is Just in Case Manufacturing?

JIC manufacturing follows a risk-averse inventory management strategy. It keeps extra inventory levels to handle demand fluctuations, supplier delays, and unexpected events, ensuring businesses maintain steady production and avoid costly disruptions in their supply chain.

Companies using this method hold more raw materials and finished goods than needed to meet customer demand reliably. The approach focuses on building a safety net in the supply chain to avoid production delays and maintain steady operations despite disruptions.

Core Principles of the Just in Case Strategy

Just in case inventory helps businesses fulfill orders during demand spikes or when suppliers face delays. Companies prioritize having enough inventory available over cutting costs. This increases storage costs and carrying costs but reduces risk.

The strategy leans on higher stock levels as a buffer to protect against supply chain disruptions and unexpected production process issues.

Just in Case Inventory in Practice

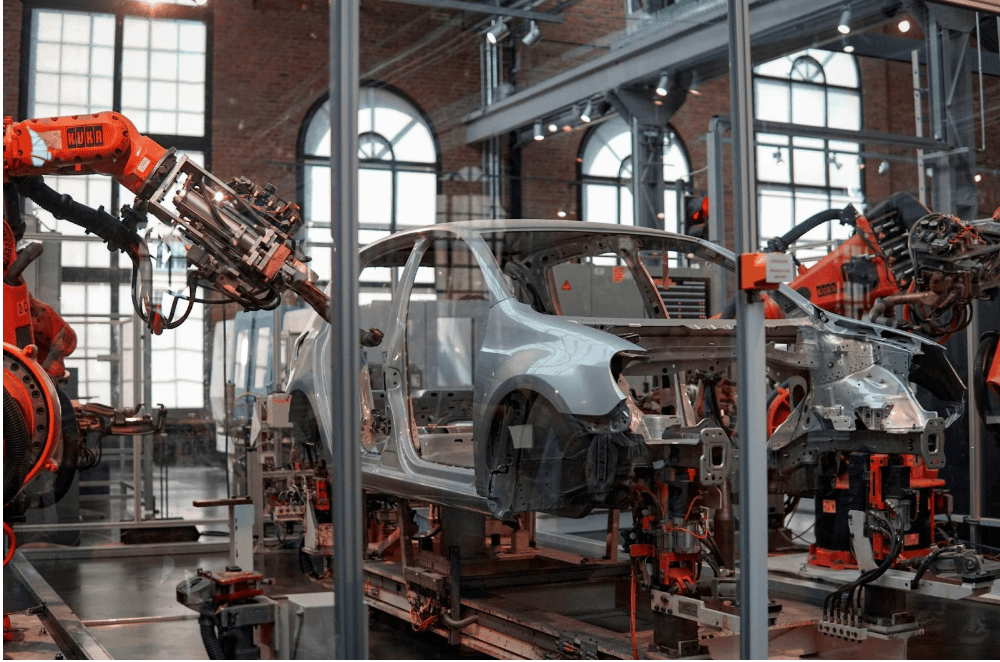

Industries with unpredictable supply chains, such as automotive and healthcare, rely on just-in-case inventory. These sectors face risks like natural disasters or sudden demand fluctuations. They hold extra raw materials and components to avoid halts on the assembly floor.

Companies with less supplier stability often adopt this JIC inventory strategy to ensure they can continue production and maintain customer satisfaction.

Just in Case vs. Just in Time

Just in case and just in time represent two very different inventory management strategies. While just-in-case focuses on holding extra stock for stability, just-in-time minimizes inventory to reduce waste through JIT inventory management practices.

Both approaches affect how companies handle supply chain management and respond to risks and costs.

Inventory Approach and Supply Chain Philosophy

Just-in-time emphasizes a lean production process that reduces waste and lowers inventory costs. It depends on reliable suppliers and tight supply chain visibility to maintain low inventory levels and support efficient, timely manufacturing operations.

Just in case focuses on readiness, holding extra inventory to absorb shocks and maintain supply chain flexibility. Companies adopting a just-in-case approach accept higher warehousing costs to secure production continuity.

Storage and Carrying Costs

Holding more stock in JIC manufacturing increases storage costs and carrying costs. Companies need larger warehouses and higher working capital to manage excess inventory, which ties up funds and raises overall inventory management expenses.

Just-in-time cuts these costs by ordering materials only as needed. While JIT lowers overhead, it leaves little room for error if suppliers fail or demand suddenly rises.

Risk and Flexibility

JIC manufacturing acts as a safety net against supply chain disruptions and supplier delays. It provides companies with more flexibility to manage unexpected demand spikes and sudden interruptions in production or supply.

JIT strategy struggles without steady supplier stability and faces higher risks if the supply chain breaks down. JIC reduces reliance on perfect timing, making it better suited for uncertain markets.

Hybrid Inventory Management Models

Combining just-in-case with just-in-time creates a hybrid inventory management model. This approach balances cost savings with risk management. Businesses keep essential safety stock while cutting excess inventory costs elsewhere.

A hybrid model allows companies to respond to sudden demand spikes without the full burden of holding extra inventory all the time.

Benefits of Just-in-Case Inventory Strategies

JIC inventory strategies offer strong protection against disruptions and demand changes. Companies gain stability and readiness by holding extra stock. The following benefits explain why some businesses prefer this inventory management strategy despite higher costs.

Business Continuity and Risk Management

Holding JIC inventory helps businesses avoid halts during supplier delays or unexpected events. It creates a safety stock that keeps the production process running smoothly. Companies protect their cash flow by reducing the risk of costly downtime.

Maintaining extra raw materials and products ensures operations continue through supply chain disruptions or demand fluctuations.

Meeting Customer Demand and Avoiding Lost Sales

Extra inventory boosts customer satisfaction by preventing stockouts. When companies keep more inventory, they can respond quickly to customer orders without delay. This approach lowers the chance of lost sales and damaged reputation.

Holding enough stock helps companies consistently meet customer demand and avoid stockouts, which improves customer satisfaction and strengthens their position in competitive markets over time.

Preparing for Seasonal and Sudden Demand Changes

Seasonal peaks or sudden demand spikes challenge many businesses. JIC manufacturing offers flexibility by holding extra stock in advance, allowing companies to respond quickly and meet forecast demand without disrupting production.

This strategy allows companies to react faster and avoid scrambling for supplies during busy periods. Planning reduces stress on the assembly floor and helps maintain steady output.

Drawbacks of the Just in Case Model

Holding extra stock requires more resources and comes with tradeoffs between security and efficiency. While it reduces risks, JIC manufacturing often raises costs and affects overall operations.

Higher Costs and Storage Requirements

Larger inventory levels increase storage costs and holding costs. Companies must spend more on warehouses and staff to manage excess inventory. This ties up working capital and impacts the company’s cash flow. Higher overhead means less flexibility for other investments or growth opportunities.

Inventory Waste

Excess inventory risks becoming obsolete or spoiling, especially for perishable or seasonal goods. Holding more stock than needed can lead to significant inventory waste. Companies lose money on expired or outdated products and must manage returns or write-offs. Effective inventory management software can reduce these risks, but cannot eliminate them.

Impact on Profitability

Just in case inventory reduces cost savings from lean operations. Long-term holding costs add up and affect the bottom line. Businesses face challenges balancing risk mitigation with maintaining healthy profits. Overreliance on extra stock may lower efficiency and increase cash flow implications, reducing the overall company’s profitability.

Managing Just in Case Inventory Effectively

Making JIC manufacturing work requires careful planning and smart tools. Without thoughtful execution, holding extra stock can waste resources. Managing JIC inventory efficiently means tracking stock levels, forecasting demand, and balancing risk with cost.

Using Inventory Management Software

Inventory management software helps businesses track just-in-case inventory accurately. It monitors reorder points and delivers real-time updates on stock levels to improve decision-making and reduce excess inventory.

Using software tools improves inventory management by reducing errors and avoiding excess stock. Companies gain better control over case inventory management and streamline their supply chain processes.

Data-Driven Demand Planning

Analyzing past sales, market trends, and seasonal patterns supports smarter demand planning. Using data to forecast demand helps companies avoid over-reliance on guesswork and better manage their inventory levels and cash flow.

Businesses can adjust JIC strategy to avoid holding too much or too little inventory. Data-driven planning improves customer satisfaction by ensuring the right products are available at the right time.

Balancing JIT and JIC for Better Outcomes

Combining just-in-time and just-in-case strategies creates a flexible inventory approach. Companies must identify critical items needing case inventory and prepare for possible supplier delays to keep production running smoothly.

Reducing additional storage costs while keeping a safety net helps optimize cash flow. Balancing these methods supports smooth production without unnecessary waste.

When Just in Case Manufacturing Makes Sense

Choosing JIC manufacturing depends on the business context and supply chain risks. It fits certain scenarios better than others.

- Unreliable Suppliers: When suppliers face frequent delays or quality issues, holding extra stock prevents production delays.

- Long Lead Times: Items with long delivery times require more JIC inventory to keep production steady.

- Global Shipping Delays: Shipping interruptions increase risk; extra stock acts as a buffer against unpredictable transport issues.

- Seasonal or Unpredictable Customer Demand: Sudden spikes or seasonal shifts call for higher stock levels to meet demand quickly.

- Highly Regulated or High-Risk Products: Products needing strict compliance or careful handling benefit from a stable supply secured by case inventory.

Matching the right inventory strategy to a company’s model and supply chain management environment improves resilience and efficiency.

Conclusion

Just in case manufacturing builds extra JIC inventory to manage risks like supplier delays and demand fluctuations. It differs from just-in-time manufacturing by prioritizing readiness over reducing inventory costs.

Businesses facing unpredictable supply chains or sudden changes in demand benefit most from this inventory management approach. Using a JIT model or JIT system offers less inventory and cost savings but requires reliable suppliers.

Effective JIC inventory management balances stock levels with demand. Combining it with just-in-time inventory helps reduce risks when demand slows, giving companies less concern about supply disruptions.