Artificial Intelligence in Supply Chains: Game On

From decision support to reverse logistics, here’s how AI activates supply chain capabilities and takes systems to another level.

How Agentic AI Can Reshape Procurement

By Victor Kushch, Co-founder & CTO, Fairmarkit

Agentic AI can elevate the procurement team’s operating model and strategic influence. Unlike traditional AI tools that require human intervention at every step, agentic AI introduces AI-driven agents that operate autonomously, using advanced reasoning and decision-making to manage sourcing tasks end-to-end. These agents don’t just assist in procurement—they execute strategies, adapt to new data in real time, and optimize outcomes with minimal oversight.

Agentic AI can elevate the procurement team’s operating model and strategic influence. Unlike traditional AI tools that require human intervention at every step, agentic AI introduces AI-driven agents that operate autonomously, using advanced reasoning and decision-making to manage sourcing tasks end-to-end. These agents don’t just assist in procurement—they execute strategies, adapt to new data in real time, and optimize outcomes with minimal oversight.

An AI agent can analyze supplier databases, vet candidates against compliance standards, negotiate pricing, and finalize contracts. As a result, the procurement function operates as a business accelerator rather than a bottleneck.

The rise of agentic AI won’t replace procurement professionals; it will redefine their role. As AI agents take over execution-heavy tasks, procurement teams will shift their focus to strategic oversight, AI-driven decision-making, and supplier relationship management.

Agentic AI isn’t just about automating tasks—it’s about embedding AI-driven reasoning into procurement. One of the most valuable skill sets won’t be running sourcing events manually but designing and optimizing AI agent strategies to drive business impact.

Start with the Fundamentals to Unlock Value

By Shawn Vo, President and CTO, Denim

AI could add $1.2 trillion in value to supply chains globally, a McKinsey report estimates. But capturing that value depends on how—and where it’s applied. Across the freight industry, AI is already accelerating everyday work: speeding up quoting, interpreting documents, and enabling faster, more accurate payments. But it’s not one-size-fits-all.

AI could add $1.2 trillion in value to supply chains globally, a McKinsey report estimates. But capturing that value depends on how—and where it’s applied. Across the freight industry, AI is already accelerating everyday work: speeding up quoting, interpreting documents, and enabling faster, more accurate payments. But it’s not one-size-fits-all.

Choosing the Right AI Tools for the Job

Not all AI is created equal. Some systems follow rigid rules, others analyze past data to predict what’s next, and some make sense of messy, unstructured information. Think of it like this:

- Rules-based logic handles consistent, structured workflows

- Predictive models support planning with historical trends

- Language models and AI agents spot anomalies in documents and freeform data

Here are three core principles for using AI effectively in freight operations:

1. Start with Usefulness—Not Possibility

The best way to evaluate AI isn’t by asking what it could do. It’s by asking what’s slowing your team down today.

The most effective use cases aren’t trying to do everything. They’re solving well-scoped problems—like interpreting inconsistent paperwork, reducing repetitive approvals, or helping teams manage workflows that don’t scale well with headcount.

A good starting point: look for tasks that are high-volume, repeatable, and follow a general pattern—but still need occasional human judgment. That’s where AI tends to shine.

2. Place Guardrails on AI

AI systems in freight often touch sensitive data—everything from banking details and invoices to customer rates and load data. That’s why security and oversight aren’t features to layer on later—they have to be part of the system from day one.

If you’re building or buying AI into your business, it helps to ask: What kind of data will this system use? Can we explain how decisions are made? How will we track its performance, accuracy, and fairness over time?

One way to think about AI safety is the “Swiss cheese” model. A single layer of protection might have holes, but stack enough layers—training, monitoring, human review, audit logs—and those gaps start to disappear. Each layer strengthens the system. In practice, this might include:

- Training AI models with relevant, representative data

- Monitoring performance as things change

- Keeping a human involved in higher-stakes workflows

- Logging decisions and outcomes for transparency

Whether it’s reviewing a document or verifying a payment, it should always be clear what the AI is doing—and why.

3. Keep People in the Loop

AI can take on a lot of the repetitive work that slows teams down—but that doesn’t mean every decision should be fully automated. Some tasks—like updating sensitive payment information or reviewing exceptions—still benefit from human oversight. That’s why it’s important to design systems that support people, not remove them from the process entirely.

One helpful approach is to treat AI as a recommendation engine. It can process data, identify patterns, and handle the routine cases, while flagging the ones that need a second look. For higher-impact actions, having a person make the final call adds a layer of confidence and accountability.

6 Actions for Responsible AI

Balancing AI’s benefits and environmental challenges requires governance, responsible investment, and strategic integration. Experts recommend 6 moves:

1. Ground corporate strategy and decision-making in the responsible implementation of AI and its sustainability impacts. Consider both short-term efficiency and productivity gains and long-term ripple effects on corporate, human, and planetary health.

2. Track and report. Communicate the commitments from the executive team and board on how AI impacts will be measured and reported. This should include energy and water sources, usage trends, emissions, and offsets in other areas of operations.

3. Focus on systems Innovation. Deploy AI to accelerate internal innovation in electrified manufacturing processes, optimized supply chain routes, evaluation of alternative transportation modes, and preferences for “clean” investment portfolios.

AI is rapidly being integrated into SCM tech stacks across many workflow areas. Today, AI is digitizing and standardizing data, so trust is building quickly because the manual approach to processing data is slow and error prone. It will take time to trust AI to autonomously make decisions, such as rerouting freight, but that day is closer than we all think.

4. Ensure sustainability across suppliers. Demand the same level of sustainability commitments and disclosures by external suppliers, vendors, and partners to ensure alignment and continual progress toward strategic and sustainability goals.

5. Seek federal advocacy. Join with peers and industry associations to advocate for incentives, such as the extension and expansion of federal tax credits to accelerate and fund the widespread adoption of sustainable manufacturing and logistics practices.

6. Foster cross-industry networks. Engage in diverse and multi-disciplinary forums to broker explicit commitments that humans will drive the training of AI. Leaders across industries, utilities, governments, NGOs, and academics are best positioned to develop innovative solutions and a comprehensive approach that balances environmental, social, and governance (ESG) factors.

Source: Balancing the Benefits of AI & the Health of Our Planet: How to Embrace the Benefits of AI Technology without Sacrificing Environmental Progress, a white paper spearheaded by the Women’s Leadership Center at Williams Bay.

Source: Balancing the Benefits of AI & the Health of Our Planet: How to Embrace the Benefits of AI Technology without Sacrificing Environmental Progress, a white paper spearheaded by the Women’s Leadership Center at Williams Bay.

Forming the Core of Supply Chain Resilience

By Paul Pallath, VP of Applied AI, Searce

AI repositions supply chains from reactive systems into predictive, adaptive ecosystems. By analyzing vast volumes of real-time data from IoT sensors, GPS trackers, and enterprise systems, AI can anticipate early signals of disruptions—whether it’s a material shortage, factory downtime, or a transportation delay—and recommend preemptive actions. This is not speculative decision-making; it’s grounded in live, multi-source intelligence.

Digital twins take this a step further. These AI-powered virtual replicas of entire supply chains allow organizations to simulate complex scenarios and test responses in a safe, dynamic environment. The ability to explore “what-if” situations, identify weak links, and optimize operations without disrupting real-world activities is nothing short of a breakthrough in operational resilience, made possible by AI.

Imagine a manufacturing leader facing a potential port closure. In the past, they would have scrambled reactively. Today, with AI-driven agility, they pivot. AI enables hyper-accurate demand forecasting by analyzing real-time market conditions, regional buying patterns, and even social sentiment. Businesses can adjust production schedules, inventory levels, and distribution routes to meet demand more precisely, reduce waste, and prevent overstock or understock situations. The result is a supply chain that’s not just faster, but smarter.

Sustainability goals are also benefiting from AI’s precision. Blockchain and AI work together to create environmentally responsible and transparent supply chains. AI tracks emissions, energy use, and waste, helping companies hit ESG targets with actionable insights. Blockchain adds accountability by verifying sustainable sourcing and ethical labor practices, building trust with consumers and stakeholders.

Communication—often the hidden friction point in global operations—is being reshaped. Large language models (LLMs) are removing long-standing language and documentation barriers, enabling collaboration and generating contextual insights in real time. Teams around the world stay aligned, informed, and ready to act, no matter the time zone or language.

Ultimately, the future of supply chain leadership isn’t just about speed or cost efficiency. It’s about using AI-driven intelligence not just to respond to disruption, but to anticipate it, shape strategy, and drive innovation.

AI Tackles Tariff Volatility

By Rohit Tripathi, VP of Industry Strategy, Manufacturing, RELEX

Today’s volatile trade environment doesn’t allow for decision lag. AI-powered supply chain planning platforms are changing how companies adapt and how quickly they can sense and respond to disruptions.

These sophisticated tools can process thousands of variables simultaneously, like tariff rates, supplier lead times, country-of-origin rules, and inventory positions, enabling manufacturers to simulate tariff scenarios and calculate cost impacts in minutes. The systems can also evaluate supplier alternatives, model recipe changes, and recalculate landed costs across multiple regions in real time—giving companies the agility to sense, evaluate, and respond to disruptions almost as quickly as they happen.

The decisions companies face after policy changes are even more challenging when you consider how complex modern supply chains are. A product’s bill of materials might originate from six different countries, each with varying tariff constraints and lead times. When a CEO wants to know how a new policy will affect a product mix in one market, AI can analyze each component’s tariff exposure and model various scenarios.

The ability to model different scenarios is also helping brands shift toward modular risk management. Brands can simulate complex trade-offs and reconfigure business rules on the fly to see how it impacts their topline and their profitability. This allows companies to embed adaptability into their planning processes instead of managing uncertainty through massive capital investments.

For example, a coconut-based beverage company effectively managed tariff-related supply chain adjustments and reconfigurations across a global supply chain spanning 15 factories and 20+ market warehouses. The ability to represent tariff structures within the AI solution meant these were included in optimization algorithms as a key input, not an afterthought calculation on a spreadsheet.

In demand planning, AI helps decipher consumer response by separating true baseline demand from short-term distortions, when customers “pre-buy” to avoid a tariff change. It can pick out subtle patterns in consumer behavior that are invisible to human analysts and optimize SKU planning by analyzing historical sales trends.

Retailers can then make more informed, proactive decisions about pricing, inventory levels, and assortment adjustments, separating the true demand signal from the noise that may come through.

Optimizing Retail Returns

By Pedro Ramos, Chief Revenue Officer, Appriss Retail

AI can help retailers analyze real-time returns data across all channels—online, in-store, and call centers—while preserving consumer anonymity. It evaluates behavior patterns like purchase frequency, return habits, and anomalies such as the use of multiple identities, addresses, or payment methods. This gives retailers’ systems a more nuanced understanding of each transaction, enabling them to approve, warn, or decline returns based on actual risk, not rigid rules.

AI-driven systems provide an omnichannel view of returns, identifying root causes such as product quality, logistical issues, serial returners, or potential abuse (like wardrobing), while also recognizing and rewarding trustworthy customers. Retailers can use these insights to power a positive impact on margin and drive more sustainable shopping options—to reduce returns and limit environmental impact.

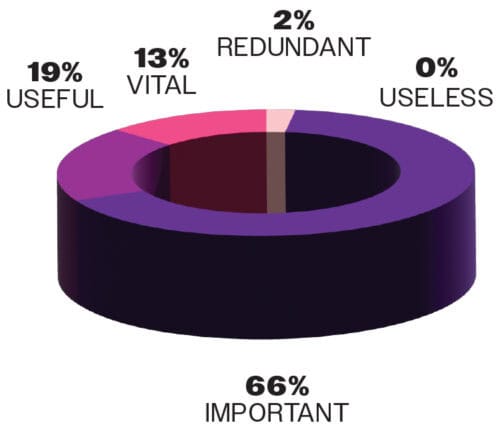

98%

respondents who work for organizations that use AI say it’s useful, important, or vital, according to the recent Deep Analysis report AI Readiness in Transportation and Logistics Back-Office Operations. AI is seen as a transformative force that enhances efficiency and reduces operational costs, with only 2% not agreeing:

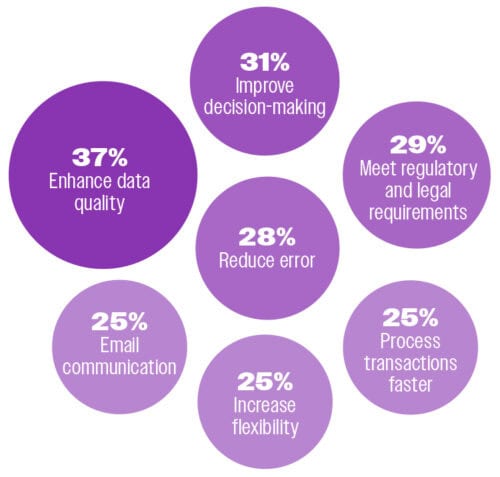

For this research project, Hyperscience and the Council of Supply Chain Management Professionals (CSCMP) worked with Deep Analysis to gather and analyze data to shed light on the impact of AI. Respondents use AI to:

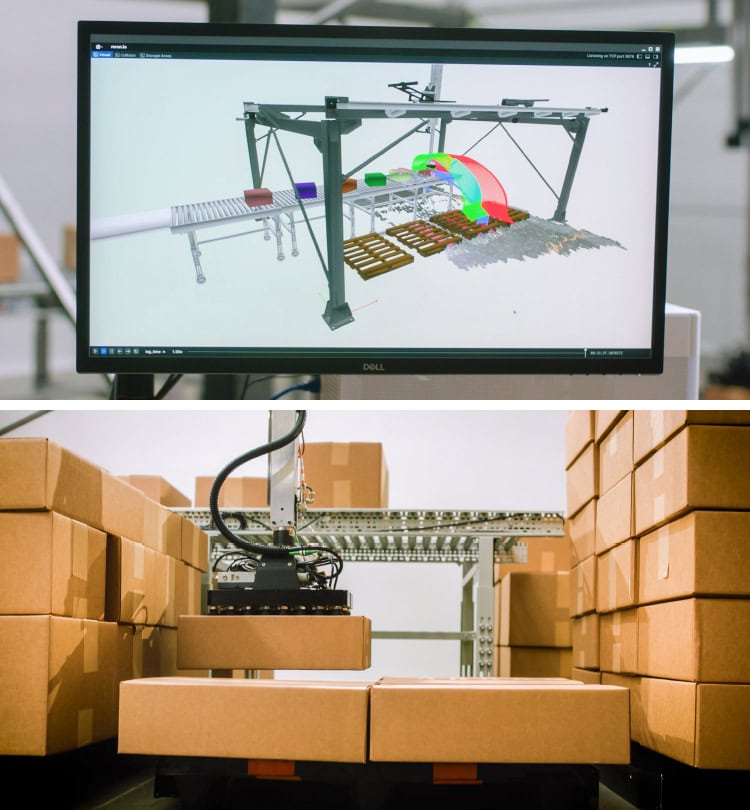

Stack ’Em High, Stack ’Em Tight

Precise pallet stacking for both inbound and outbound warehouse materials handing? Artificial intelligence is guiding the way.

Powered by an AI vision system based on foundation models, AmbiStack from Ambi Robotics is a robotic stacking solution that analyzes, tracks, and picks items while performing quality control checks. Its AI planning system, built on simulation-to-reality technology, eliminates the need for real-world data collection, letting companies deploy it quickly. Sim2Real reinforcement learning optimizes pallets for density and stability without advance knowledge of item sets or sequencing.

AI launchpad

The shipping container turns into an AI agent. Net Feasa’s new platform transforms the container into an AI agent that can initiate auctions among prospective customers seeking cargo slots on vessels. The AI-enabled container can self-manage, negotiate, and secure optimal bids.

New AI agent helps other AI agents. Logistics provider C.H. Robinson created an AI agent that automates the process of classifying freight, helping shippers, particularly small-to-medium businesses, which are heavy users of both LTL shipping and email. The new agent assists other AI agents: It determines the class and code for a shipment and helps other agents turn emailed tenders into accurate orders.

AI, where’s my inventory? SC Codeworks, a provider of warehouse management solutions, introduced CODI, designed to help warehouse operators and decision-makers access insights from their data. The AI-powered data retrieval and conversational command agent, built into SC Codeworks’ platform, acts as an in-house expert on the user’s own warehouse operations.

Meet scheduling expert, Alan. FourKites unveiled Alan, an AI-powered digital worker for yard scheduling. Working with AutoGate AI, a computer vision technology solution, it can streamline the way facilities manage arrivals and departures. Alan handles the entire appointment lifecycle across communication channels.

AI optimizes decision-making. The Kraft Heinz Company is transforming how decisions are made across its global supply chain by using AI-powered decision intelligence from Aera Technology. Aera Technology’s Aera, a decision intelligence agent, improves decision making—from support to augmentation to full decision automation.

AI enables robotic cross-dock. Warp secured new capital—$10 million—to fund the expansion of its AI systems and the launch of its first fully robotic cross-dock, a flagship facility that will automate the entire freight lifecycle from inbound receiving and dimensioning to smart sortation and outbound dispatch.