Supply Chain Control Tower: Definition, Types, and Implementation

In today’s global economy, supply chain management has become increasingly complex. The challenge for businesses is to effectively manage these complex supply chains while ensuring the timely delivery of products, minimizing costs, and maintaining quality.

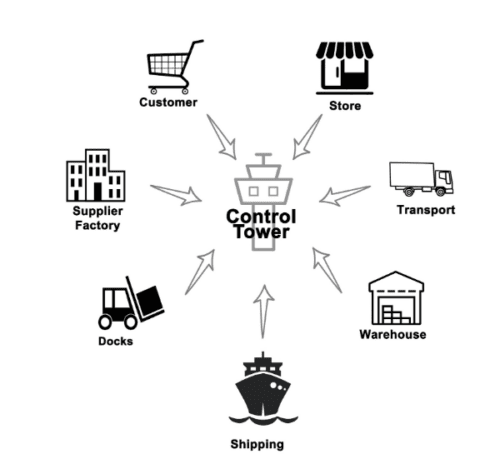

One solution to this challenge is the implementation of supply chain control towers (SCCT) that act as a centralized hub for monitoring and managing all aspects of the supply chains. Let’s discuss the concept of a supply chain control tower, its benefits, and the critical components required to implement one successfully.

What Is a Supply Chain Control Tower?

A SCCT is a central hub that provides end-to-end visibility and control over a company’s supply chain. It is a digital platform that integrates data from multiple sources and provides real-time insights into the various processes and activities within the entire supply chain.

Supply chain managers use the SCCT to monitor and manage the flow of goods and services. They also identify potential disruptions or bottlenecks in the supply chains using the SCCT, which also enables collaboration and communication among stakeholders in the supply chain, such as suppliers, manufacturers, and customers.

The SCCT uses advanced supply chain analytics and machine learning algorithms to analyze data and identify patterns, trends, and anomalies in the supply chain. It allows supply chain managers to make more informed decisions, proactively mitigate risks, and optimize operations.

Types of Supply Chain Control Towers

There are different types of SCCTs, depending on the scope and complexity of the supply chain network. Here are some common types of SCCT:

- Logistics and transportation

- Fulfillment

- Inventory control

- Supply assurance

- End-to-end SCCT

What is the Purpose of a Control Tower?

The purpose of a SCCT is to provide end-to-end visibility and control over an entire supply chain network. The goal is to improve supply chain performance by optimizing operations, reducing costs, minimizing risks, and enhancing customer service. Having a SCCT enables managers to monitor and manage supply chain operations, maximize performance, and respond to changing market conditions and customer demands. Companies that implement this structure achieve greater control over their supply chain.

What Are the Three Essential Capabilities of a Supply Chain Control Tower?

Let’s look at the three main control tower capabilities.

- Real-time end-to-end visibility. A supply chain control tower provides end-to-end supply chain visibility, including suppliers, production, logistics, inventory, and customers. It collects data from various sources and provides real-time insights into the performance of the supply chains.

- Prescriptive, predictive decision-making. Predictive analytics uses historical data to forecast future events, such as demand fluctuations or supply chain disruptions. Prescriptive analytics use optimization algorithms to recommend the best action. It enables supply chain managers to make data-driven decisions based on insights generated by the platform.

- Proactive collaboration with partners. A SCCT also facilitates collaboration and communication among stakeholders in the supply chains. It enables stakeholders to share information and work together more effectively to proactively manage the supply chain.

Potential Challenges With Establishing a Supply Chain Control Tower

Various factors can make establishing a SCCT challenging. One of the biggest challenges is data quality and accessibility, as SCCTs rely on high-quality data from multiple sources to generate insights and recommendations. Sometimes, data may be siloed or fragmented, making it difficult to integrate and analyze.

Establishing a SCCT requires a significant investment in technology and infrastructure, which may only be feasible for some companies. SCCTs need advanced technologies, such as artificial intelligence and machine learning. They also require robust infrastructure, including servers, networks, and storage, to support these expensive technologies.

Companies must also have the right skills and talent to operate the SCCT. Among the required skills are data analytics, technology, and supply chain management skills. These skills require significant investments to acquire or train existing employees.

Another challenge is stakeholder buy-in and collaboration, as SCCTs require input and participation from various stakeholders across the supply chain. It can be challenging due to organizational culture, priorities, and differences in incentives.

Additionally, organizations may need to address security and privacy concerns. Integrating multiple systems and data sources can result in multiple and often complex security and privacy concerns, requiring organizations to provide critical security and privacy infrastructure and policies.

Finally, there may be resistance to change, as stakeholders may hesitate to adopt new technologies or processes that disrupt existing working methods.

How Do You Implement a Supply Chain Control Tower?

Implementing a SCCT is a complex process. It involves integrating data from various sources, building analytics and reporting capabilities, establishing governance and communication structures, and piloting and refining the platform.

There are different approaches to implementing a SCCT, including buying a commercial platform or building a custom solution, and each option has its pros and cons. Let us look at the different approaches to implementing a SCCT.

Buying a SCCT

Buying a SCCT refers to purchasing a pre-existing software platform from a vendor that provides the capabilities necessary for managing and optimizing a supply chain.

Pros of buying a SCCT:

- Faster implementation time due to pre-existing platform and infrastructure.

- Access to established technology and expertise from the vendor.

- Lower upfront investment compared with building a custom solution.

Cons of buying a SCCT:

- Limited customization and control over the platform.

- Dependence on the vendor for ongoing maintenance and support.

Building a SCCT

This refers to creating a custom solution for managing and optimizing a supply chain, often using a combination of in-house and third-party technologies.

Pros of building a SCCT:

- Customize and control the platform to meet specific needs.

- Ability to adapt to changing conditions and requirements.

- Potential for cost savings over time compared to buying a commercial solution.

Cons of building an SCCT:

- Longer implementation time due to developing a custom solution.

- Need for in-house expertise and resources to build and maintain the platform.

- Higher upfront investment compared to buying a commercial solution.

Here is how to implement a supply chain control tower in your organization.

Identify Business Goals

One of the critical steps in implementing a SCCT is identifying the business goals the platform is intended to achieve. These goals will guide the selection of technology, data sources, supply chain analytics, and reporting capabilities.

It is essential to involve stakeholders across the supply chain to ensure that the identified goals reflect the organization’s needs and are achievable.

The plans are a benchmark for evaluating the success of the SCCT implementation and continuously monitoring and improving the platform over time.

Research and Analyze

Research and analysis involve evaluating different commercial platforms and assessing in-house capabilities. It also includes identifying the technology, data sources, analytics, and reporting capabilities that align with the organization.

Companies must also evaluate the ROI of the SCCT implementation and determine the cost-benefit analysis of buying a commercial platform versus building a custom solution.

By researching and analyzing, organizations make informed decisions and ensure that the SCCT implementation process is aligned with their specific needs and requirements, leading to a more effective and efficient supply chain operation.

Design and Deploy the Control Tower

This process involves customizing and configuring the selected platform to meet the organization’s specific needs and requirements. It also involves integrating data from the identified sources and establishing governance and communication structures to facilitate stakeholder collaboration.

In this process, it is essential to define the key performance indicators (KPIs) and metrics that will be tracked and reported through the SCCT. Once the platform is designed and configured, it is piloted and tested to ensure it functions correctly and meets the identified requirements.

Deployment involves rolling out the platform to the broader organization and ensuring stakeholders receive training to use it effectively.

Monitor and Adjust

By continuously monitoring the performance of the SCCT against the identified KPIs and metrics, users can identify areas for improvement, making necessary adjustments to ensure that the platform delivers the expected business value.

Companies must establish a feedback loop and regularly engage with stakeholders across the supply chain to solicit feedback about the platform’s performance.

SCCT performance should be periodically reviewed and evaluated against the organization’s goals. You should adjust to ensure the platform effectively addresses the identified needs and requirements.

Tips for Choosing a Supply Chain Control Tower

Choosing the right SCCT is critical to achieving supply chain visibility and optimizing supply chain management. When selecting an SCCT, organizations should consider several factors:

- Alignment of the SCCT with the organization’s specific needs and requirements

- Scalability and flexibility of the SCCT

- Robust analytics and reporting capabilities

- Data security and governance features

- Data quality and output

Final Thoughts

SCCTs have become an essential tool for managing complex supply chains and optimizing supply chain management. While there may be challenges in establishing an SCCT, the benefits are significant.

With the right SCCT, organizations can improve supply chain efficiency, enhance visibility, reduce costs, and ultimately drive business growth.