What Is Your Shipper-Logistics Provider Relationship Costing You?

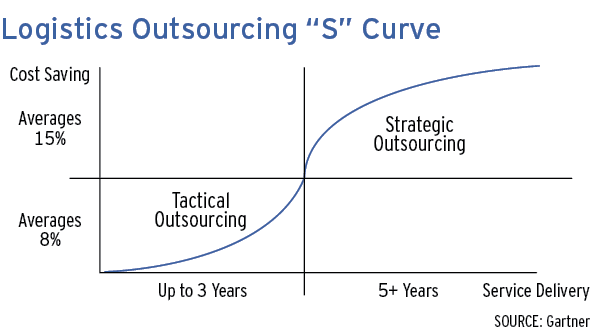

Two to three years is the average logistics provider relationship. The leading reason a shipper becomes dissatisfied with its provider is the lack of strategic initiative. Strength in planning and execution simply does not provide enough value to maintain a relationship over the long term. Innovation—the application of better solutions that meet new requirements, unarticulated needs or existing market needs—is required to avoid stagnant results and costs within a supply chain. Too often shippers are left weighing the cost of change and the challenge of finding a new provider against the savings potential when aligned with a true supply chain partner. Companies cut cost to survive; they innovate to prosper.

In a business where the length of the contract usually determines the length of the relationship, it is important to consider why supply chain cost savings flatten after a year or two. At the onset of the relationship, shippers consider savings potential and are often focused on procurement savings, including the promise of continuous improvement, that can be delivered by a new provider.

The problem with this approach is that procurement savings, while dependent on the purchasing power of the provider, are tightly linked to market conditions. In a down market, bid savings become a shiny object while results in years two and three are overlooked. The provider with the best packaging on its proposal becomes the front-runner. As the business is implemented, the shipper sees cost benefits in year one and typically does not see process improvement, productivity enhancements or cost reductions in subsequent years.

The challenge for shippers considering a new logistics provider is understanding how to evaluate the overall potential of the relationship. Key items to evaluate include:

- Tenure of relationships with the provider’s current customers. Long-standing partnerships demonstrate supply chain savings provided year-over-year, not just early in the relationship.

- The provider’s experience with characteristics similar to the shipper’s business. While a shipper often focuses on experience in its vertical, the maturity of its customer’s supply chain is also a critical factor. A rapidly growing business experiences different problems and requires different solutions to maintain service to its customers while managing supply chain costs.

- Examples of cost savings projects, not just ROI calculations, must be provided. Case studies should demonstrate proficiency.

- Reward structure for provider’s personnel. Delivering supply chain savings should be part of the performance criteria to ensure the team is not overly focused on tactical execution.

Be sure you dig into the promise of continuous improvement when evaluating your current and future supply chain partners. Ensuring results are expected beyond year one’s savings is the most critical part of the equation that is most often missed. In response to the question, what does your logistics provider cost you? The answer is savings beyond year one!